Hot-rolling H-shaped steel containing and vanadium boride and having excellent low-temperature impacttoughness and preparation method of hot-rolling H-shaped steel

A low-temperature impact toughness, H-shaped steel technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of large fluctuations in impact absorption energy, low operability of steel properties, and low pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

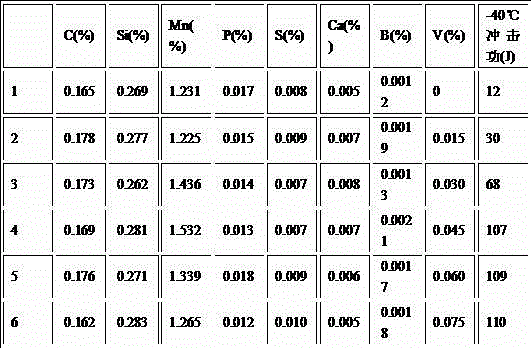

[0022] Example 1: Boron-vanadium-added Q345 H-shaped steel, product specification 700×300×13×24, the mass fraction of the steel is as follows (%): C 0.16~0.18, Si 0.26~0.29, Mn 1.20~1.27, P 0.012~0.018, S 0.007~0.010, Ca 0.005~0.008, B 0.0012~0.0023, V 0~0.076, the balance is Fe and trace impurities.

[0023] During the smelting process, control the mass percentage of gas in the profile billet: [N]≤80 ppm, [O]≤100 ppm. According to the above-mentioned smelting composition of Q345, the rolling process temperature is controlled as follows: heating temperature 1250~1280 ℃, billet opening temperature 1180~1225 ℃, final rolling temperature 790~830 ℃. During the universal rolling process, the billet stays for 35 seconds, and the cumulative reduction ratio is 60%.

[0024] The impact test adopts the Charpy V-shaped impact specimen, and the length direction is along the longitudinal direction of the flange of the H-shaped steel product.

[0025] See the experimental results figure ...

Embodiment 2

[0028] Example 2: boron-vanadium-added Q345 H-shaped steel, product specification 350×350×12×19, the mass fraction of steel is as follows (%): C 0.14~0.17, Si 0.25~0.30, Mn 1.31~1.39, P 0.01~0.018, S 0.005~0.010, Ca 0.005~0.008, B 0.0013~0.0022, V 0.035~0.05, the balance is Fe and trace impurities.

[0029] During the smelting process, control the mass percentage of gas in the profile billet: [N]≤80 ppm, [O]≤100 ppm. According to the above-mentioned smelting composition of Q345, the rolling process temperature is controlled as follows: heating temperature 1250~1280 ℃, billet opening temperature 1180~1230 ℃, final rolling temperature 760~810 ℃. During the universal rolling process, the billet stays for 15-50 seconds, and the cumulative reduction ratio is more than 55%. The impact test adopts the Charpy V-shaped impact specimen, and the length direction is along the longitudinal direction of the flange of the H-shaped steel product.

[0030] The experimental results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com