Method for preparing vanillyl alcohol by utilizing bacterial reduced vanillin

A technology of vanillin and vanillyl alcohol, which is applied in the field of preparation of vanillyl alcohol, can solve the problems of chemically synthesizing vanillyl alcohol such as long reaction time, large amount of solvent, and low conversion rate, and achieves good application prospects, high conversion yield and excellent reaction conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Activated bacteria

[0019] Take a ring of Acetobacter xylinum ATCC23770 from the agar slant medium where the strains are preserved, and insert it into the liquid seed medium (mannitol, glucose, sucrose or glycerin 25g, peptone 3g, yeast extract 5g, water 1L, pH3 .5, sterilized at 121°C for 20 minutes), cultured at 160 rpm at 30°C for 12 hours to activate the bacteria;

[0020] (2) Expansion of bacterial strain cells

[0021] Add the seed liquid containing 6% (v / v) into the liquid medium (glucose, mannitol, sucrose or glycerin 25g, peptone 3g, yeast extract 5g, water 1L, pH3.5, sterilized at 121°C for 20min) medium, cultured on a shaking table at 20°C and 100r / min or statically cultured for 12 hours before use;

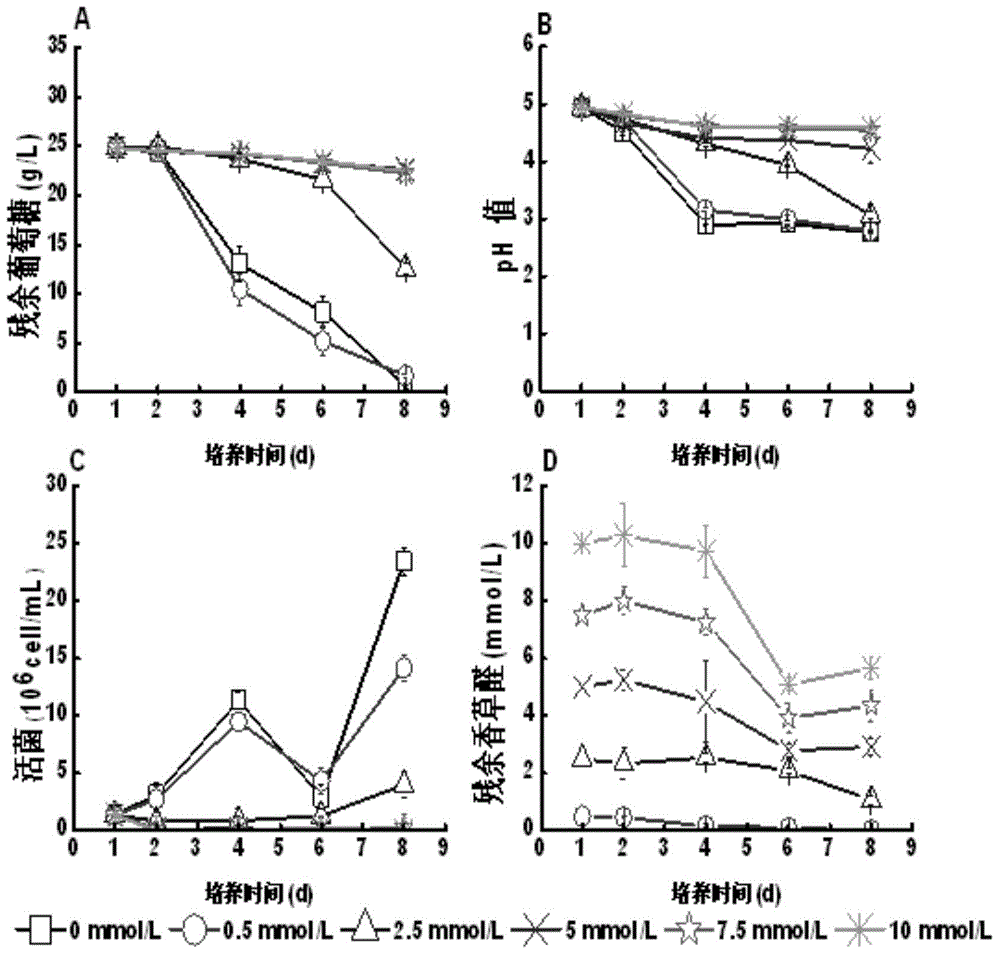

[0022] (3) Adding vanillin to prepare vanillyl alcohol

[0023] After a large amount of flocs are formed in the culture medium, add the sterile filtered vanillin solution to the culture medium respectively, so that the final concentration of vanillin in ...

Embodiment 2

[0027] (1) Activated bacteria

[0028] Take a ring of Acetobacter xylinum ATCC23770 from the agar slant medium where the strains are preserved, and insert it into the liquid seed medium (mannitol, glucose, sucrose or fructose 25g, tryptone 3g, yeast extract 5g, water 1L, pH 5.5, sterilized at 121°C for 20 minutes), cultured at 160 rpm at 30°C for 18 hours to activate the strains;

[0029] (2) Expansion of bacterial strain cells

[0030] Add the seed liquid containing 8% (v / v) into the liquid medium (glucose, mannitol, sucrose or fructose 25g, tryptone 3g, yeast extract 5g, water 1L, pH5.5, sterilized at 121°C for 20min ) in a shaker culture at 30°C and 250r / min or static culture for 18 hours before use;

[0031] (3) Adding vanillin to prepare vanillyl alcohol

[0032] After a large amount of flocs are formed in the culture medium, add the sterile filtered vanillin solution to the culture medium respectively, so that the final concentration of vanillin in the culture medium ...

Embodiment 3

[0034] (1) Activated bacteria

[0035] Take a ring of Acetobacter xylinum ATCC23770 from the agar slant medium where the strains are preserved, and insert it into the liquid seed medium (mannitol, glucose, sucrose or fructose 25g, tryptone 3g, yeast extract 5g, water 1L, pH 5.5, sterilized at 121°C for 20 minutes), cultured at 30°C at 160 rpm for 24 hours to activate the strains;

[0036] (2) Expansion of bacterial strain cells

[0037] Add the seed liquid containing 10% (v / v) into the liquid medium (mannitol, glucose, sucrose or fructose 25g, tryptone 3g, yeast extract 5g, water 1L, pH5.5, sterilized at 121°C for 20min ) in a shaker culture at 25°C and 150r / min or static culture for 48 hours before use;

[0038] (3) Adding vanillin to prepare vanillyl alcohol

[0039] When a large amount of flocs are formed in the culture medium, add the sterilized and filtered vanilla solution to the culture medium to make the final concentration of vanilla in the culture medium reach 3.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com