Skin care soap containing Spina Gleditsiae and Mythic Fungus, and its making method

A production method and technology of skin care soap, applied in the field of skin care soap, can solve problems such as skin damage and environmental pollution, and achieve the effect of safe and simple production process, hair care, anti-dandruff skin itching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

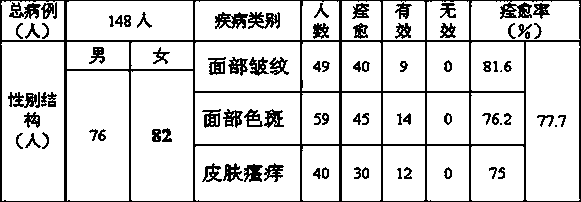

Examples

Embodiment 1

[0050] Present embodiment is to prepare saponins skin care soap of the present invention, comprises following process steps:

[0051] (1) Weigh saponins and Ganoderma lucidum dry products, slice them separately, and the weight ratio of saponins and Ganoderma lucidum is 3:1;

[0052] (2) Put saponin slices and ganoderma lucidum slices into two dipping tanks respectively, add appropriate amount of water and soak for 8-12 hours;

[0053] (3) Preparation of ganoderma lucidum concentrate: put the mixture of ganoderma lucidum slices and water obtained in step (2) in a cooking pot, add water to 20-25 times the weight of saponins dry weight, and boil over fire , filter to remove slag, continue to boil and concentrate, while stirring, until it is thin and thick;

[0054] (4) Preparation of saponin concentrate: put the mixture of saponin slices and water obtained in step (2) in a cooking pot, add water to 2.5-3 times the weight of saponin dry weight, and use fire to Stew for about 4-5...

Embodiment 2

[0061] Present embodiment is another kind of process of preparing saponins skin care soap of the present invention, comprises following processing step:

[0062] (1) Weigh saponins and Ganoderma lucidum dry products, slice them separately, and the weight ratio of saponins and Ganoderma lucidum is 3:1;

[0063] (2) Put saponin slices and ganoderma lucidum slices into two dipping tanks respectively, add appropriate amount of water and soak for 8-12 hours;

[0064] (3) Preparation of ganoderma lucidum concentrate: put the mixture of ganoderma lucidum slices and water obtained in step (2) in a cooking pot, add water to 20-25 times the dry weight of saponins, and boil over fire , filter to remove slag, continue to boil and concentrate, while stirring, until it is thin and thick;

[0065] (4) Preparation of saponin concentrate: put the mixture of saponin slices and water obtained in step (2) in a cooking pot, add water to 2.5-3 times the weight of saponin dry weight, add soap Panc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com