Anticorrosive paint, preparation method of anticorrosive paint and oil tube coated with anticorrosive paint

A technology of anti-corrosion coatings and oil pipes, which is applied in the preparation of oil pipes with anti-corrosion coatings on the surface, and in the field of anti-corrosion coatings. It can solve the problems that cannot fully meet the anti-corrosion requirements of oil casings, easy to block pipelines, and needs to be removed, and achieve high cost performance. Construction Good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

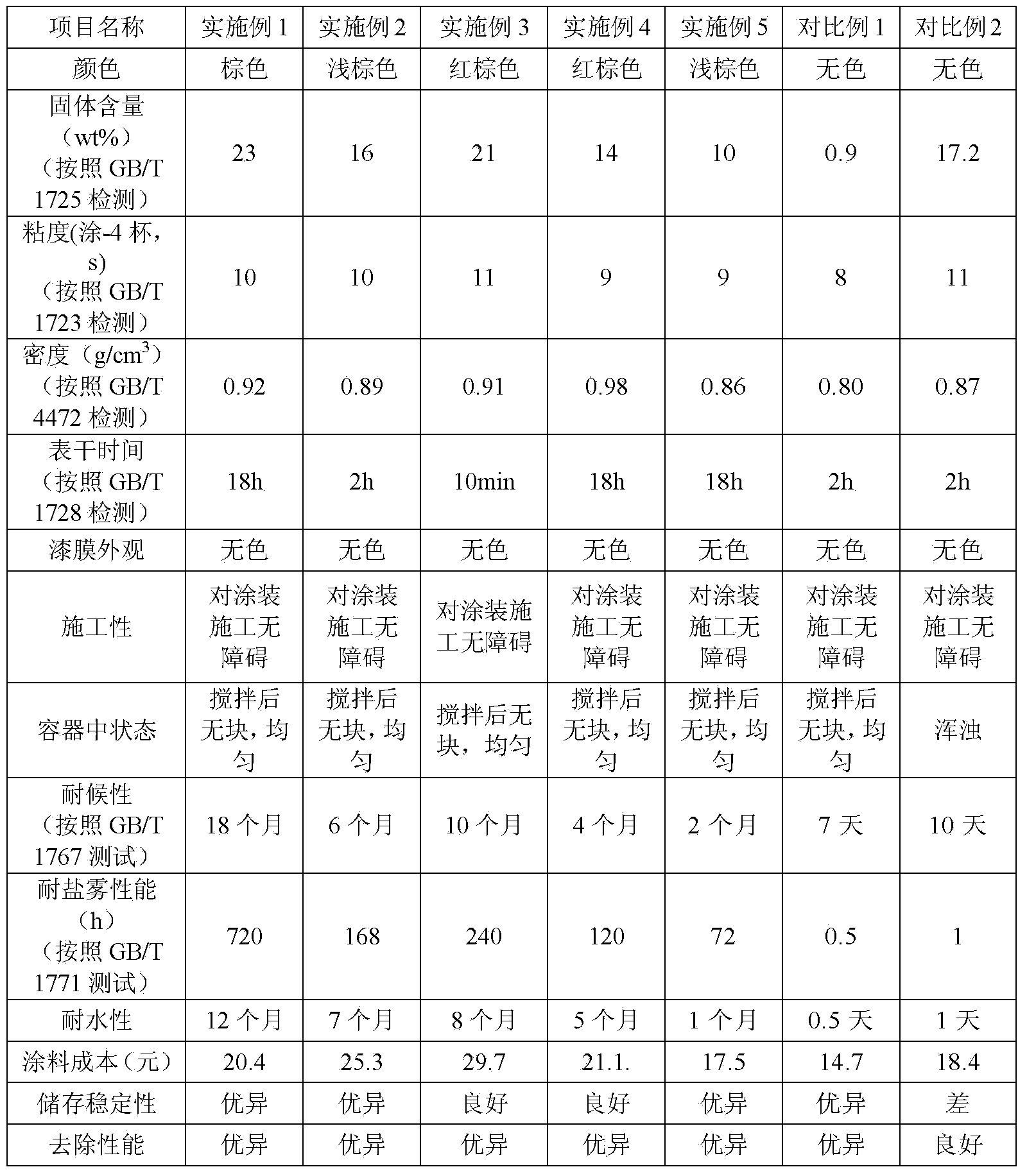

Examples

preparation example Construction

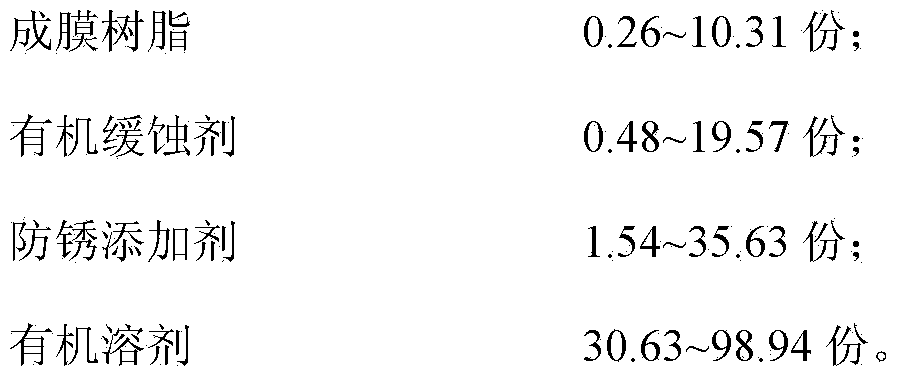

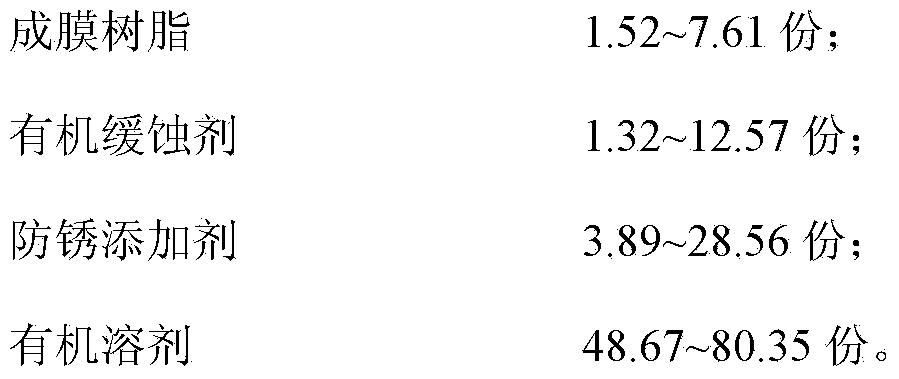

[0030] According to another aspect of the present invention, there is provided a method for preparing an anti-corrosion coating, comprising the following steps: S1, mixing the film-forming resin with part of the organic solvent, and stirring to dissolve the film-forming resin; S2, adding the dissolved film-forming resin Add organic corrosion inhibitors and antirust additives to the mixture, add the remaining organic solvent, and stir evenly to obtain anticorrosion coatings. Preferably, part of the organic solvent added in step S1 accounts for 30wt%-50wt% of the total amount of organic solvent. The purpose of adding the organic solvent step by step is to make the film-forming resin dissolve in the organic solvent better, so as to achieve the purpose of its comprehensive dissolution. In the present invention, the film-forming resin is first dissolved in an organic solvent, and the purpose is to obtain a uniformly dispersed film-forming resin. If the dispersion is not uniform, th...

Embodiment 1

[0034] In terms of parts by mass, take 5.79 parts of 210 modified phenolic resin (provided by Zhengli Chemical Co., Ltd.), and add it to 38.66 parts of aromatic solvent oil (provided by Loctite Chemical Co., Ltd., the model is s-100 solvent oil), Stir at a speed of 1500r / min until the above-mentioned modified phenolic resin is completely dissolved.

[0035] To the dissolved modified phenolic resin, add 11.21 parts of ZTH-D1821 dialkyl quaternary ammonium salt (provided by Zibo Tenghui Oil Chemical Co., Ltd.) and 25.76 parts of high-efficiency anti-rust grease (provided by Wuxi Feitian Oil Co., Ltd. ), stirred at a speed of 2000r / min for 2 hours, then added 38.66 parts of organic solvent n-butanol, stirred evenly, and obtained a temporary protective anti-corrosion coating.

Embodiment 2

[0037] In terms of parts by mass, take 1.52 parts of JY14-60 styrene-modified alkyd resin (provided by Dongguan Junyi Chemical Technology Co., Ltd.), and add it to 14.6 parts of organic solvent n-butanol. Stir at high speed until the above-mentioned modified alkyd resin is completely dissolved.

[0038] In the dissolved resin, add 8 parts of organic corrosion inhibitor ZTH-D1821 dialkyl quaternary ammonium salt (provided by Zibo Tenghui Oil Chemical Co., Ltd.), 1.6 parts of carboxymethyl amphoteric imidazoline (provided by Suizhou Tianfeng Chemical Technology Co., Ltd.) and 2.97 parts of pentasodium ethylenediamine tetramethylene phosphate (provided by Shandong Taihe Water Treatment Co., Ltd.) and 15 parts of complex soap-based grease (Great Wall 7013 grease, provided by Yunfeng, Taicang City Provided by Lubricating Oil Co., Ltd.), stirred at a speed of 2000r / min for 2 hours, added 34.07 parts of organic solvent n-butanol, stirred evenly, and obtained a temporary protective an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com