Polypropylene composition with high fluidity and high dimensional stability and preparation method thereof

A polypropylene composition and dimensional stability technology, applied in the field of high flow and high dimensional stability polypropylene composition and its preparation, can solve problems such as defects and easy appearance, achieve low shrinkage rate and wide injection molding process range , the effect of good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

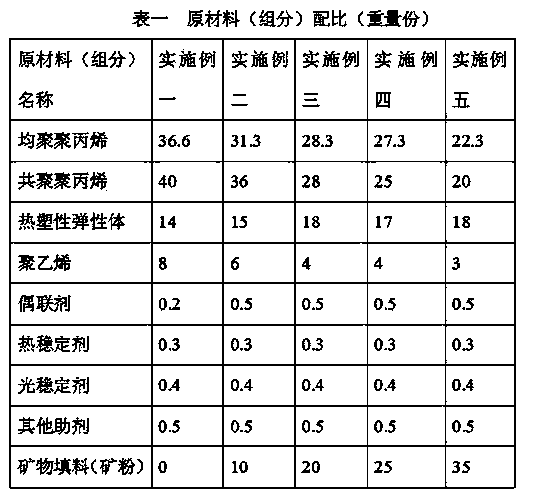

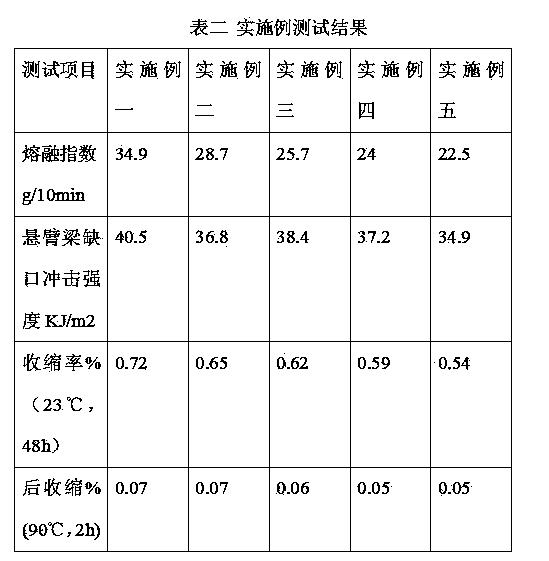

Examples

preparation example Construction

[0038] The preparation method of described high flow high dimensional stability polypropylene composition comprises the following steps:

[0039] Step 1. Add the homopolypropylene, copolymerized polypropylene, thermoplastic elastomer, and linear low-density polyethylene into the mixer for uniform mixing according to the weight ratio, then add the coupling agent for uniform mixing, and then add other additives , heat stabilizer, light stabilizer, mineral filler, mixed at a low speed for 2-8 minutes to obtain a premix.

[0040] Step 2. Add the premix obtained in step 1 to the twin-screw extruder, set the feeding frequency to 6-10Hz, the frequency of the host machine to 22-26Hz, and set the temperature of the extrusion section to 170-180°C, 190-230°C , 190-230°C, 190-230°C, 190-230°C, 185-225°C, 185-225°C, 185-225°C, 200-240°C, the extruded plastic strips are water-cooled, the water tank temperature is 20-60°C, Air-dried and pelletized to obtain a polypropylene composition with hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com