Method for preparing grade porous ZMS (Zeolite Socony Mobil)-5 molecular sieve by acid-base coupling

A technology of ZSM-5 and hierarchical pores, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of easy carbon deposition, structural collapse, damage, etc., to avoid catalyst , low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Choose ZSM-5 with a silicon-aluminum ratio of 38, ZSM-5:NaOH:H 2 O was stirred evenly at a mass ratio of 1:0.24:30 to make a slurry, placed in a water bath and heated to 80°C, and stirred for 30 minutes. Then cool to room temperature to filter, first wash with water, then wash with nitric acid, and finally dry in an oven at 110°C for 12 hours, and ion-exchange the obtained sample with ammonium nitrate. Ion exchange conditions: alkali treatment ZSM-5: NH 4 NO 3 The solid-liquid ratio is 1g:30mL, and the ion exchange temperature is 80°C. Finally, the sample is filtered, dried, and calcined at 550°C for 4 hours. The sample is designated as AT-6.

[0040] Figure 4 NH for samples AT-3 and AT-6 3 -TPD spectrum, AT-3 and AT-6 samples have three desorption peaks at 170°C, 230°C, and 470°C respectively, indicating that AT-3 has weak acid sites, medium strong acid sites and strong acid sites. But after HNO 3 In the washed samples, the amount of acid corresponding to the we...

Embodiment 2

[0042] Choose ZSM-5 with a silicon-aluminum ratio of 38, and mix ZSM-5:NaOH:H 2 O was stirred evenly at a mass ratio of 1:0.24:30 to make a slurry, placed in a water bath and heated to 80°C, and stirred for 30 minutes. Then it was cooled to room temperature, filtered, washed with water, and finally dried in an oven at 110°C for 12 hours, and the obtained sample was ion-exchanged with ammonium nitrate. Ion exchange conditions: alkali treatment ZSM-5: NH 4 NO 3 The solid-to-liquid ratio is 1g:30mL, and the exchange temperature is 80°C. Finally, the sample is filtered, dried, and calcined at 550°C for 4 hours. The sample is designated as AT-7.

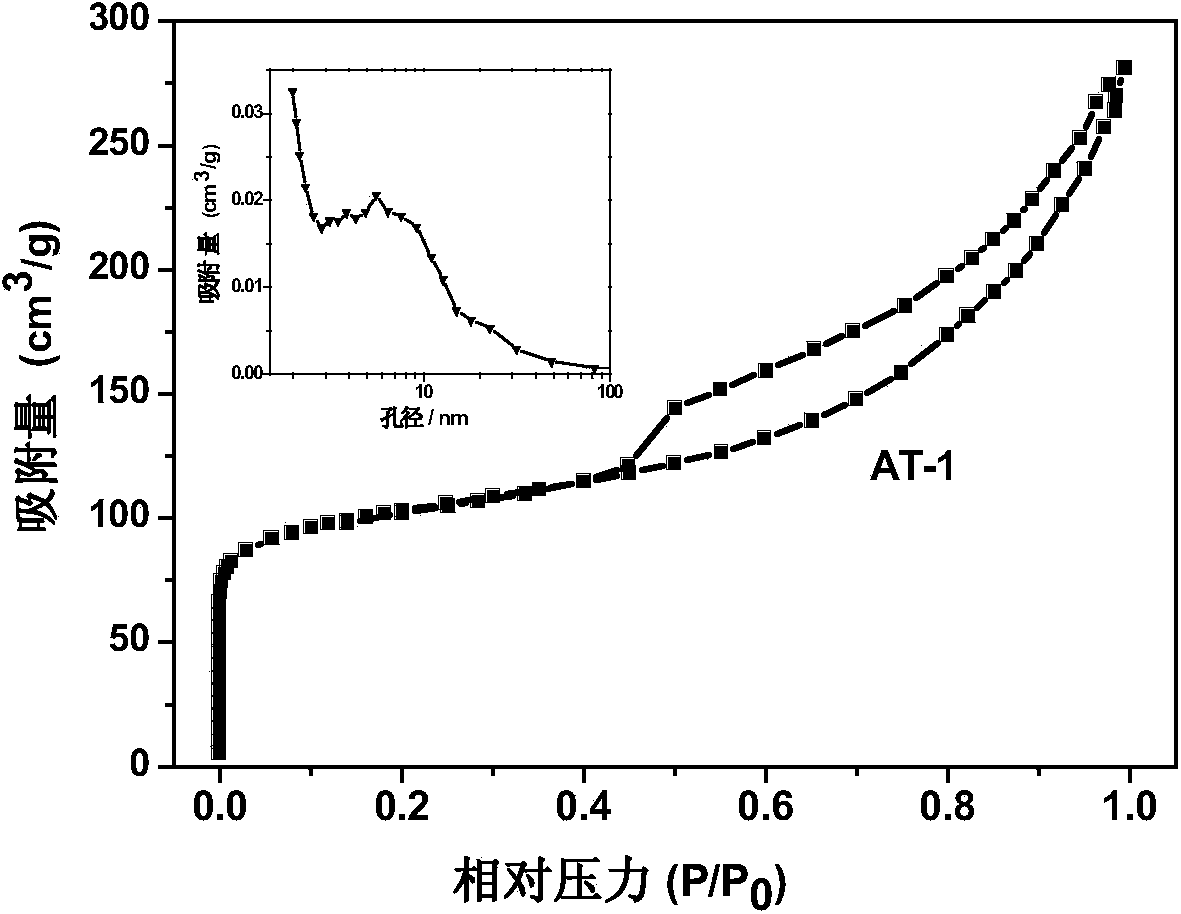

[0043] Figure 5 The adsorption-desorption curves of samples AT-3 and AT-7, after ion exchange, the specific surface area of the samples increased by 100m 2 / g, the specific surface area of micropores is basically unchanged, and the specific surface area of mesopores is increased by 70m 2 / g, the mesopore volume increased by 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com