Hot press for processing dots on surface of light guide plate

A surface processing and light guide plate technology, which is applied in the field of plastic product production, can solve problems such as high process requirements, ink chemical pollution, and injection stress affecting product flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

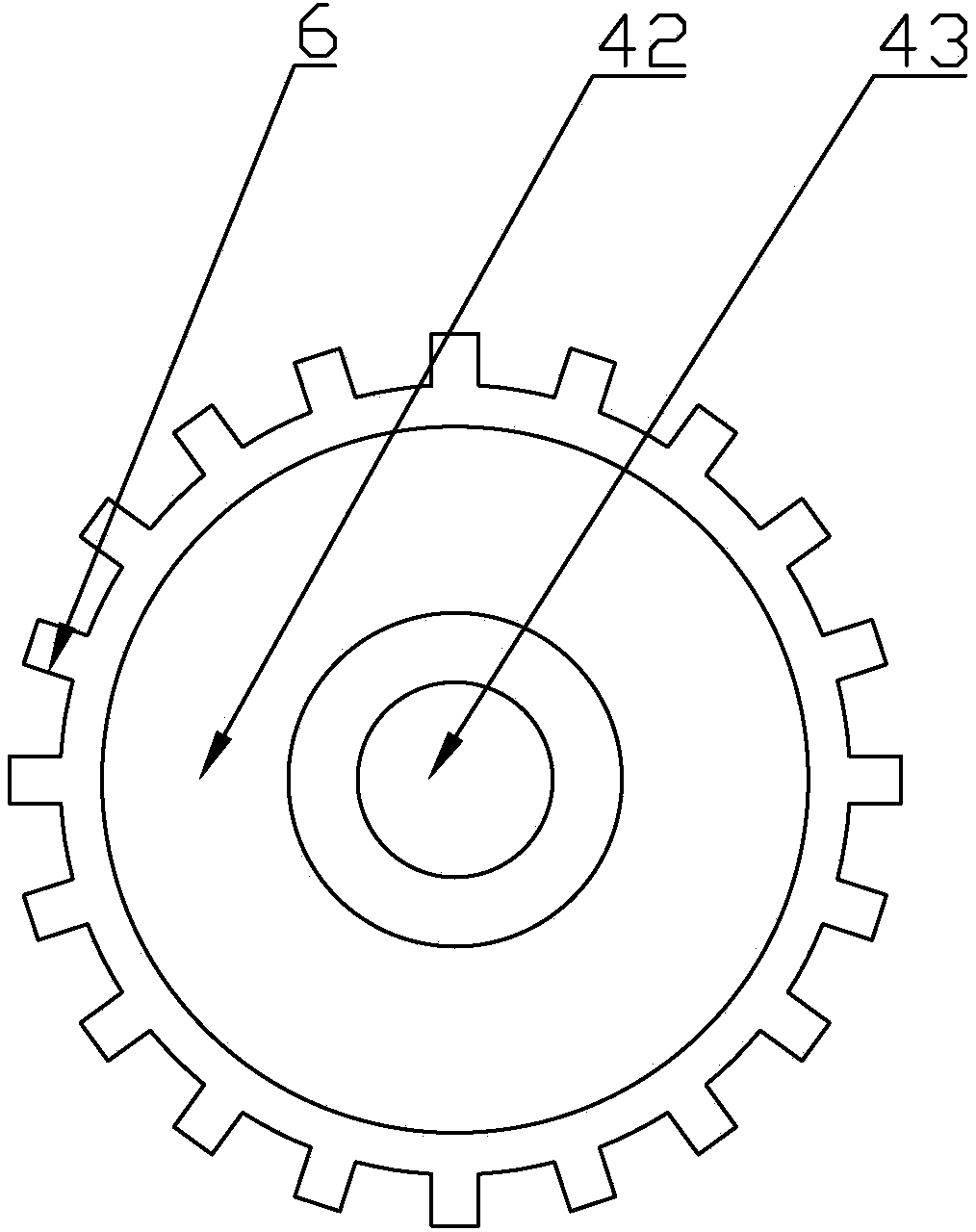

[0037] Such as figure 1 , figure 2 with image 3 As shown, a hot press machine for processing outlets on the surface of a light guide plate includes a frame 1, a manipulator 2, a transmission mechanism, a roller set, an output belt 5, a three-axis mechanism and a transmission support frame 11, and the frame 1 is equipped with The base 10, the roller support frame 12 and the lifting block 13, the roller support frame 12 is provided with a hydraulic device 121, and the described lifting block 13 is slidably installed on the roller support frame 12, and the bottom of the lifting block 13 is in contact with the hydraulic device 121 The top is in contact with each other, ensuring the stability of the lifting block 13 when lifting.

[0038] The three-axis mechanism includes a Y-axis transmission mechanism 81, an X-axis transmission mechanism 82, a Z-axis lifting mechanism 83 and a horizontal rotation mechanism 84; the horizontal rotation mechanism 84 is mounted on the Y-axis tran...

Embodiment 2

[0050] Such as figure 1 with figure 2 As shown, the rest are the same as in Embodiment 1, except that the outside of the drive roller 42 is provided with a mold belt 6. This design is for processing light guide plates that require single-sided screen dots, and there is no special limitation here. All belong to the protection scope of the present invention. Its production process is also the same as in Example 1, and will not be repeated here.

Embodiment 3

[0052] Such as figure 1 with image 3 As shown, the rest are the same as in Embodiment 1, the difference is that the outside of the fixed roller 41 is provided with a mold belt 6, this design is for processing the light guide plate that requires single-sided screen dots, and there is no special limitation here, and the same All belong to the protection scope of the present invention. Its production process is also the same as in Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com