Large capacity environmental protection dust collector

A technology of processing capacity and dust collector, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of bulky size, low efficiency of bag filter air, affecting the volume of dust collector, etc., and achieve the improvement of air filtration efficiency , reduced volume, large air filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

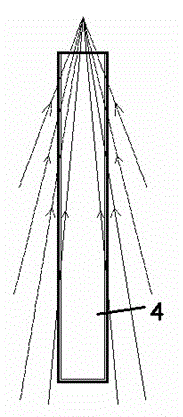

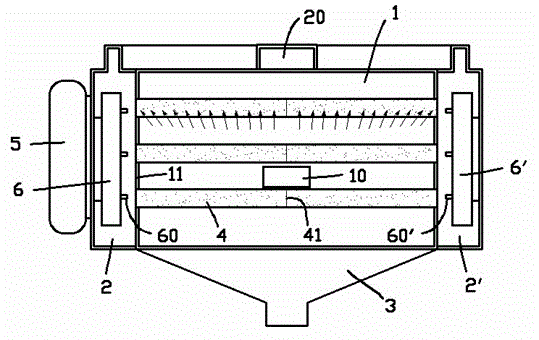

[0021] exist image 3 In the shown embodiment one, the large-capacity environmental protection dust collector includes an air filter chamber 1, an injection chamber 2, 2', an ash hopper 3, a cloth bag 4, and an injection system.

[0022] The cloth bag 4 runs through the air filter chamber 1 transversely, and is fixed on the porous plate 11, so that the gas in the air filter chamber can only enter the cloth bag 4 before entering the spray chamber 2, 2'.

[0023] Both ends of each cloth bag 4 are open ends, and the center of the internal channel of each cloth bag is provided with a partition layer 41; the injection system includes a high-pressure air bag 5, and injection parts 6, 6'; the injection chamber 2, 2' has two, symmetrically distributed on both sides of the air filter chamber 1, each spray chamber is respectively provided with a said blowing part; the two ends of each cloth bag are respectively facing a nozzle 60 of said blowing part , 60'; the housing of the air filte...

Embodiment 2

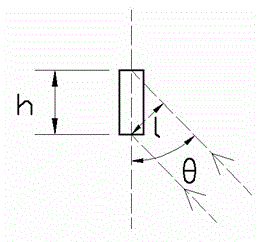

[0033] Figure 5 Shown is the second embodiment of this large-capacity environmental protection dust collector, which differs from the first embodiment in that the cloth bag is thin in the middle and thick on both sides, and is in the shape of a long circular table with two symmetrical sections connected.

[0034] Considering that even if the two ends of the cloth bag 4 are symmetrically discharged, except for the central part of the cloth bag, the rest of the air on the surface of the cloth bag still cannot enter the cloth bag vertically. The taper is equivalent to turning the surface of the bag through a certain angle relative to the direction of the intake air flow. When the taper is appropriate, the dust-laden gas can enter the bag from the surface of the bag at an angle closer to the vertical on the whole, making the bag The air filtration efficiency has been greatly improved. After testing, the appropriate taper is 0.347~0.518; since arcsin(0.347 / 2)=10°, arcsin(0.518 / 2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com