Polyoxin water-dispersible granule, its preparation method and application

A technology of polyvinylomycin and dispersible granules, applied in the field of pesticides, can solve the problems of polluting the environment, high cost of use, endangering human health, etc., and achieve the effects of reducing pollution, low cost of use, and saving packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

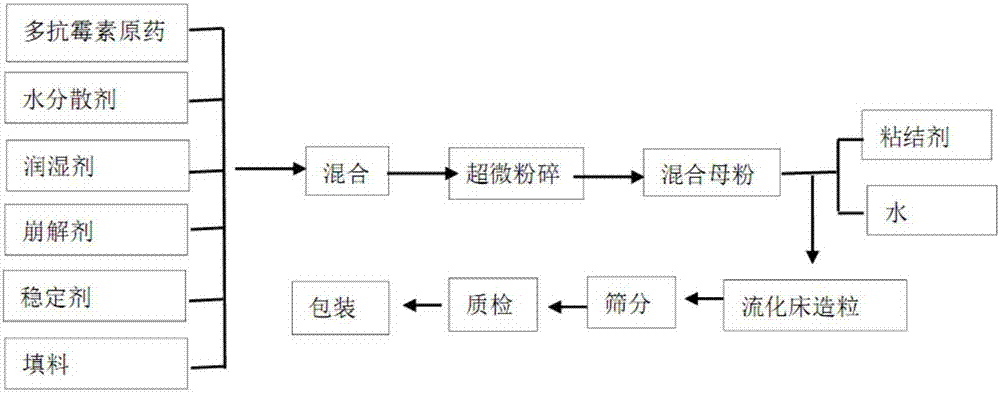

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 50% polyoxin water dispersible granules

[0037] The selection and ratio of original drug and auxiliary agent are: polyoxin original drug 85%, discount 50% accounting for 59%, dispersant NNO, sodium lignosulfonate, tripolyphosphate, polyoxyethylene polypropylene ether embedded One or two combinations in the section account for 5%, wetting agent sodium dodecylbenzene sulfonate, tea cumin, saponin, sodium lauryl polyvinyl ether sulfate, penetrant T (disecondary maleic acid One or two combinations of sodium octyl sulfonate) accounted for 4%, and one or two combinations of disintegrant sodium sulfate, sodium carboxymethyl starch, ammonium sulfate, sodium chloride, and urea accounted for 3%, Binder polyethylene glycol, carboxymethyl cellulose, dextrin, gelatin, gypsum, or a combination of two of them accounted for 3%, and stabilizers, one of tributyl phosphate, triphenyl phosphite, and BHT Or two combinations account for 0.4%, and one or two ...

Embodiment 2

[0040] The preparation of embodiment 2 50% polyoxin water dispersible granules

[0041]The selection and ratio of original drug and auxiliary agent are: 85% polyoxin original drug, 50% discount, 59%, one or two combinations of dispersant NNO, sodium lignosulfonate, and tripolyphosphate Accounting for 7%, wetting agent sodium dodecylbenzene sulfonate, tea ku, saponin, sodium lauryl polyvinyl ether sulfate or a combination of two accounted for 4.5%, disintegrating agent sodium sulfate, carboxymethyl One or a combination of sodium starch, sodium chloride, and urea accounted for 4%, and one or a combination of binder polyethylene glycol, carboxymethyl cellulose, dextrin, and gypsum accounted for 2.5%. One or two combinations of stabilizer tributyl phosphate, triphenyl phosphite, and BHT account for 0.7%, and one or two combinations of filler bentonite, white carbon black, diatomite, and clay make up 100% .

[0042] Pour the original polyoxin powder and other additives except the...

Embodiment 3

[0044] The preparation of embodiment 3 50% polyoxin water dispersible granules

[0045] The selection and ratio of original drug and auxiliary agent are: 85% polyoxin original drug, 50% discount, 59%, one or two combinations of dispersant NNO, sodium lignosulfonate, and tripolyphosphate Accounting for 9%, wetting agent sodium dodecylbenzene sulfonate, tea ku, saponin, sodium lauryl polyvinyl ether sulfate or a combination of two accounted for 5%, disintegrating agent sodium sulfate, carboxymethyl One or a combination of sodium starch, sodium chloride, and urea accounted for 5%, and one or a combination of binder polyethylene glycol, carboxymethyl cellulose, dextrin, and gypsum accounted for 2%. One or two combinations of stabilizer tributyl phosphate, triphenyl phosphite, and BHT account for 1%, and one or two combinations of fillers bentonite, white carbon black, diatomite, and clay make up 100% .

[0046] Pour the original polyoxin powder and other additives except the bin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com