Annealed free organic solar cell and production method thereof

A solar cell, annealing-free technology, applied in the field of solar cells, can solve the problems of destroying the cell structure and affecting the performance of the cell, and achieve the effect of improving transmission efficiency and reducing recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

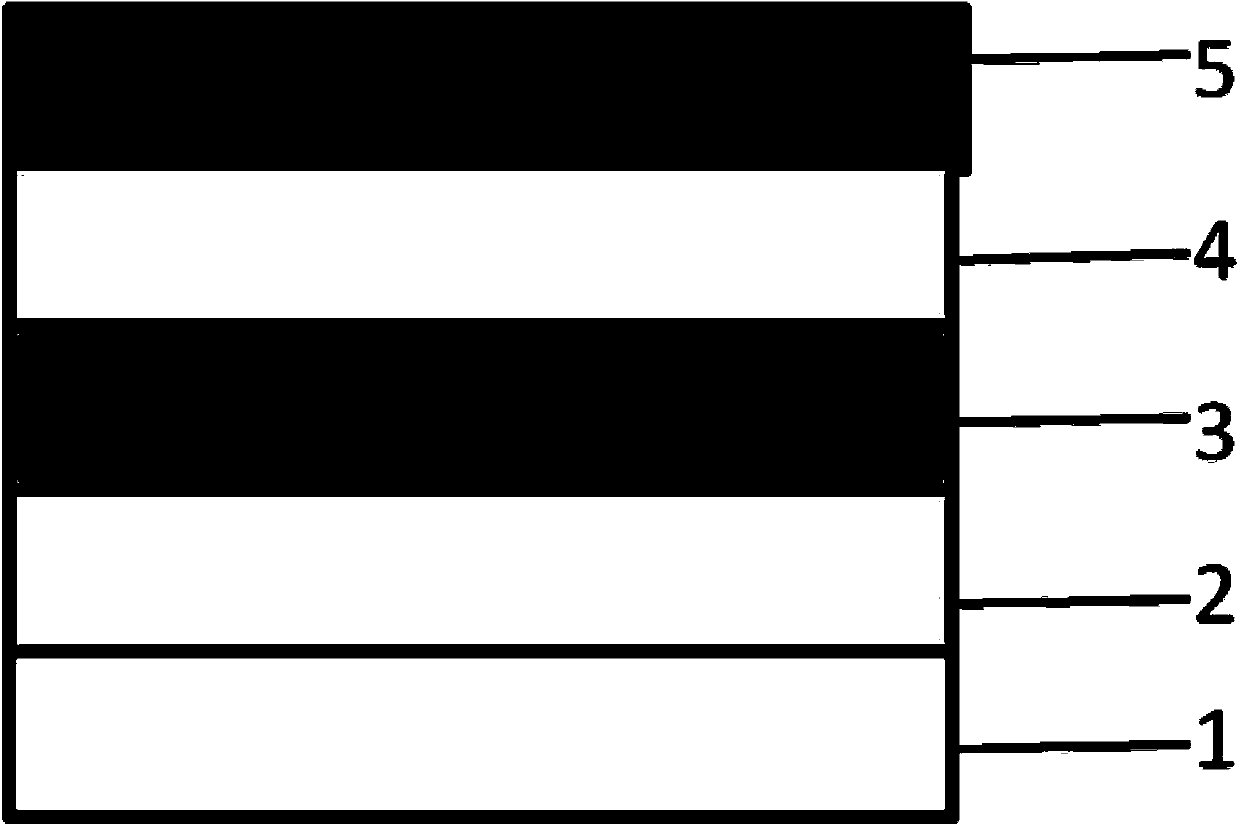

Image

Examples

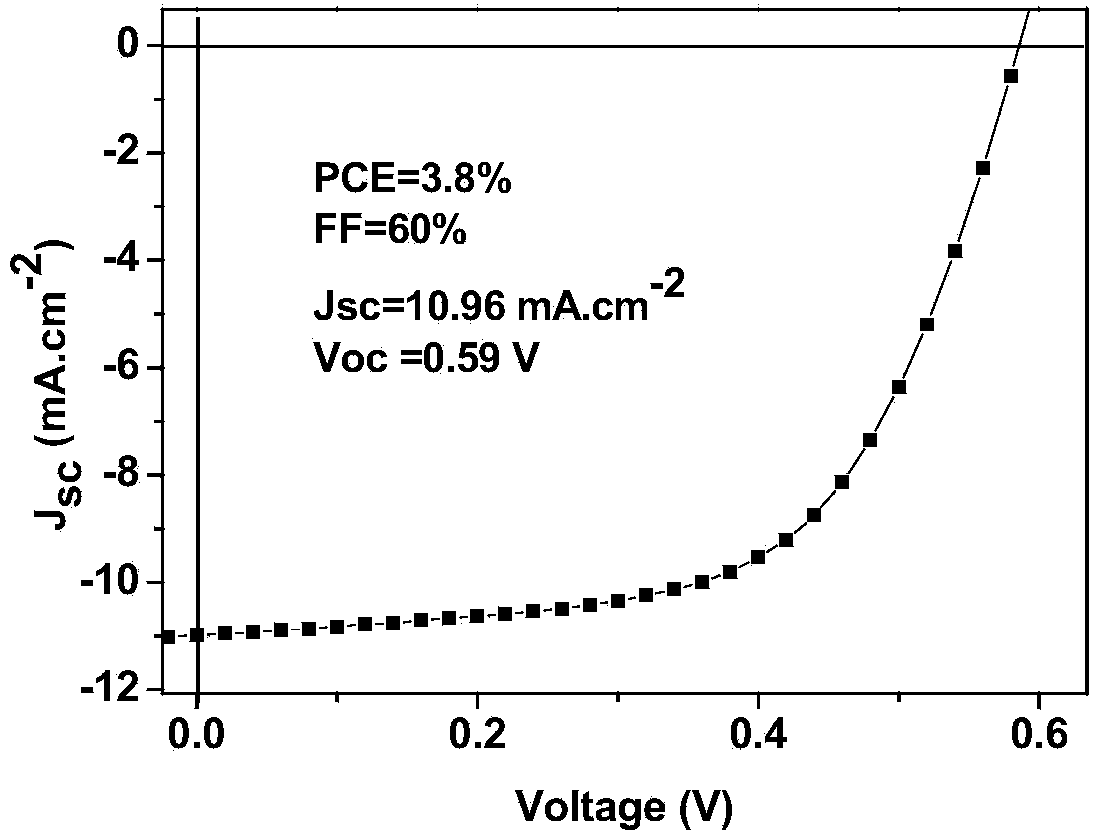

Embodiment 1

[0025] The first step is to prepare ZnO nanoparticles. Dissolve 0.799g of zinc acetate and 0.337g of potassium hydroxide in 50mL of methanol solution, then stir at 63°C for two hours to obtain a white precipitate, and centrifuge the white particles , then re-dissolved in methanol and rinsed again, then centrifuged, and washed 3 times repeatedly, and the finally obtained white precipitate was dissolved in methanol at 0.5 mg / mL and set aside. PEIE was purchased from SigmaAldrich, PEIE solution was diluted PEIE into dimethoxyethanol, the concentration of PEIE accounted for 0.04% (weight ratio) in the solution. Or refer to the literature Y. Zhou, et al, A universal method to produce low-work function electrodes for organic electronics, Science, 336, (2012) 327-332.

[0026] The second step is to configure the P3HT:PCBM organic active layer solution, 18mg of P3HT (aldrich) and 18mg of PCBM (SigmaAldrich) are dissolved in 1mL of chlorobenzene, stirred in the dark for 8 hours, and se...

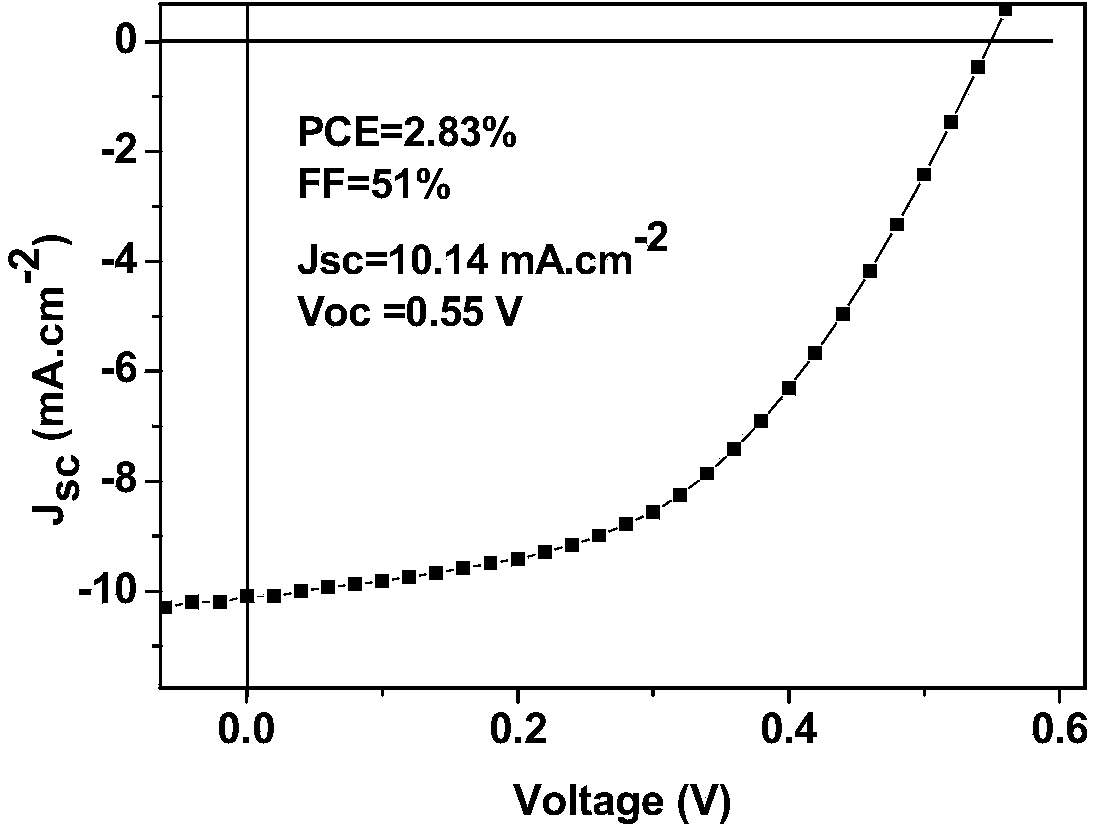

Embodiment 2

[0033] The first, second and third steps are the same as in Example 1.

[0034] The fourth step is to prepare a single-layer ZnO film; spin-coat a layer of ZnO film, take 80uL of the ZnO solution prepared in the first step, and spin-coat at a speed of 2500-3000rpm; after the spin-coating is completed, put the sample in a 150°C Bake on a hotplate for 10 minutes.

[0035] The fifth and sixth steps are the same as in embodiment 1

[0036] Through the above preparation process, the conversion efficiency of the obtained organic solar cell is 2.83%. I-V curve such as image 3 shown.

Embodiment 3

[0038] The first, second and third steps are the same as in Example 1.

[0039] The fourth step is to prepare a single-layer PEIE film; spin-coat a layer of PEIE film, take 100uL of the PEIE solution prepared in the first step, and spin-coat at a speed of 4000rpm; after the spin-coating is completed, put the sample on a hotplate at 100°C Bake for 15 minutes.

[0040] The fifth and sixth steps are the same as in Example 1.

[0041] Through the above preparation process, the conversion efficiency of the obtained organic solar cell is 2.71%. I-V curve such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com