Full-automatic detection device of automobile parts

A technology for testing equipment and spare parts, applied in the field of opto-mechanical integration testing systems, can solve problems such as failure to detect, engine running failure, defective products leaving the factory, etc., to improve the detection speed, improve the degree of automation, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, content of the present invention is described further:

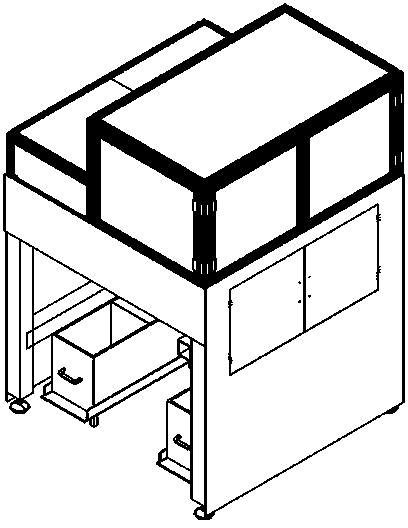

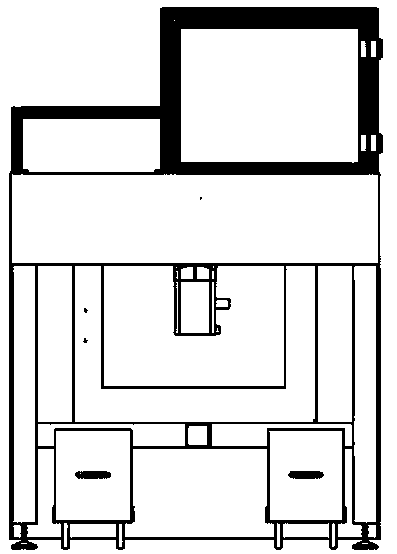

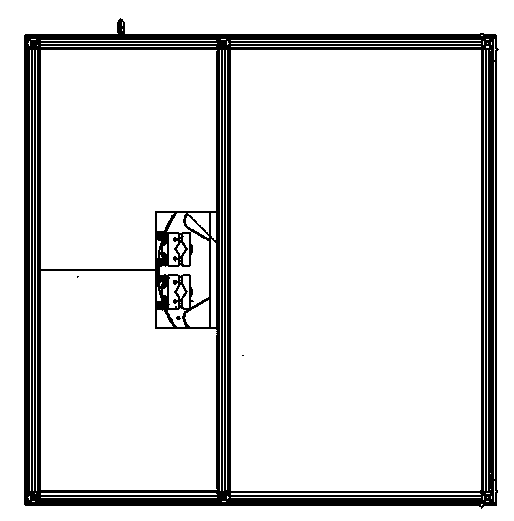

[0018] figure 1 It is a structural diagram of the main inspection table of the automatic inspection equipment for auto parts that integrates vision and robots, including the overall support of the equipment, the turntable, the light source of the defect detection camera, the feeding and discharging cylinder, and the feeding pipe. The product is precisely placed on the special fixture on the inspection platform. Through the human-computer interaction platform, select the corresponding mode for different specifications and models, start the system, the electrical system controls the mechanical arm to start automatic loading, and the vision system captures and analyzes images at the designated station. Corresponding results, and according to the results, the control mechanical system continues to automatically load materials, deliver them to designated stations, and sor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com