Spherical surface capacitive type plane level detection sensor

A level detection and sensor technology, which is applied in the fields of sensing, instrumentation and manufacturing, and machinery, can solve problems such as low sensitivity, low precision, and inability to perform digital display, and achieve high sensitivity, convenient measurement and installation, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

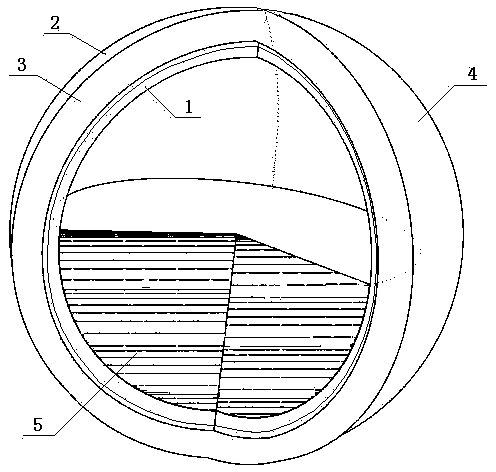

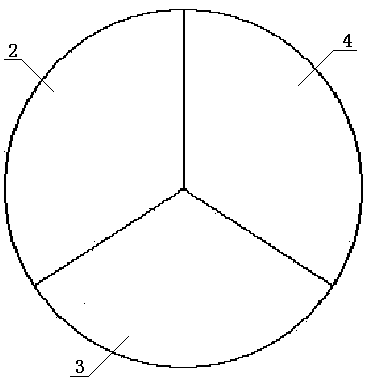

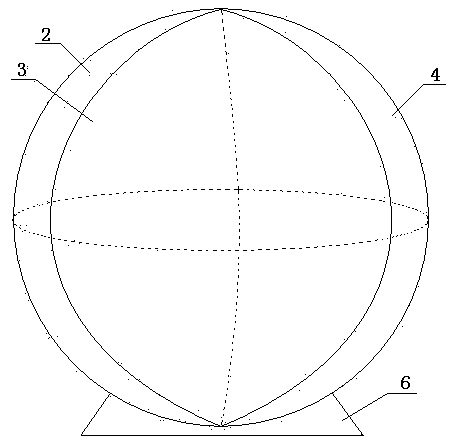

[0014] Example 1 A spherical capacitive plane level detection sensor consists of a plastic spherical surface (1), a fixed electrode A (2), a fixed electrode B (3), a fixed electrode C (4), a liquid dynamic electrode (5), a base ( 6), capacitance conversion circuit (7) and single-chip microcomputer system (8); the plastic spherical surface (1) is hollow spherical, the thickness of the spherical surface wall is uniform, the interior is sealed and filled with half-capacity conductive liquid to form a liquid dynamic electrode (5), plastic The outer surface of the spherical surface (1) is divided into thirds from the longitudinal direction, and each third of the spherical surface is coated with a metal film to form three fixed electrodes, which are fixed electrode A (2), fixed electrode B (3), fixed electrode C (4 ), the three fixed electrodes are insulated from each other, and form three variable capacitors with the liquid dynamic electrode (5); the three variable capacitors are co...

Embodiment 2

[0015] Embodiment 2 In this embodiment, the capacitance conversion circuit (7) is two capacitance-to-digital conversion chips AD7150, which directly convert the capacities of three capacitors into digital values, and the result is read by the single-chip microcomputer system (8) and calculated in the single-chip microcomputer output capacitance value. The single-chip microcomputer can calculate the inclination angle of the plane where the base (6) is located through the size of the three capacitance values.

Embodiment 3

[0016] Embodiment 3 In this embodiment, the single-chip microcomputer system (8) includes a single-chip microcomputer, a single-chip microcomputer reset circuit, a crystal oscillator, buttons and a display.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com