Outer wall system with insulation structure and manufacturing method thereof

A production method and technology for exterior walls, applied in thermal insulation, walls, building components, etc., can solve the problem of difficulty in passing the external thermal insulation system of heavy-duty finishing materials, and achieve rich decorative effects, meet weather resistance, and have a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

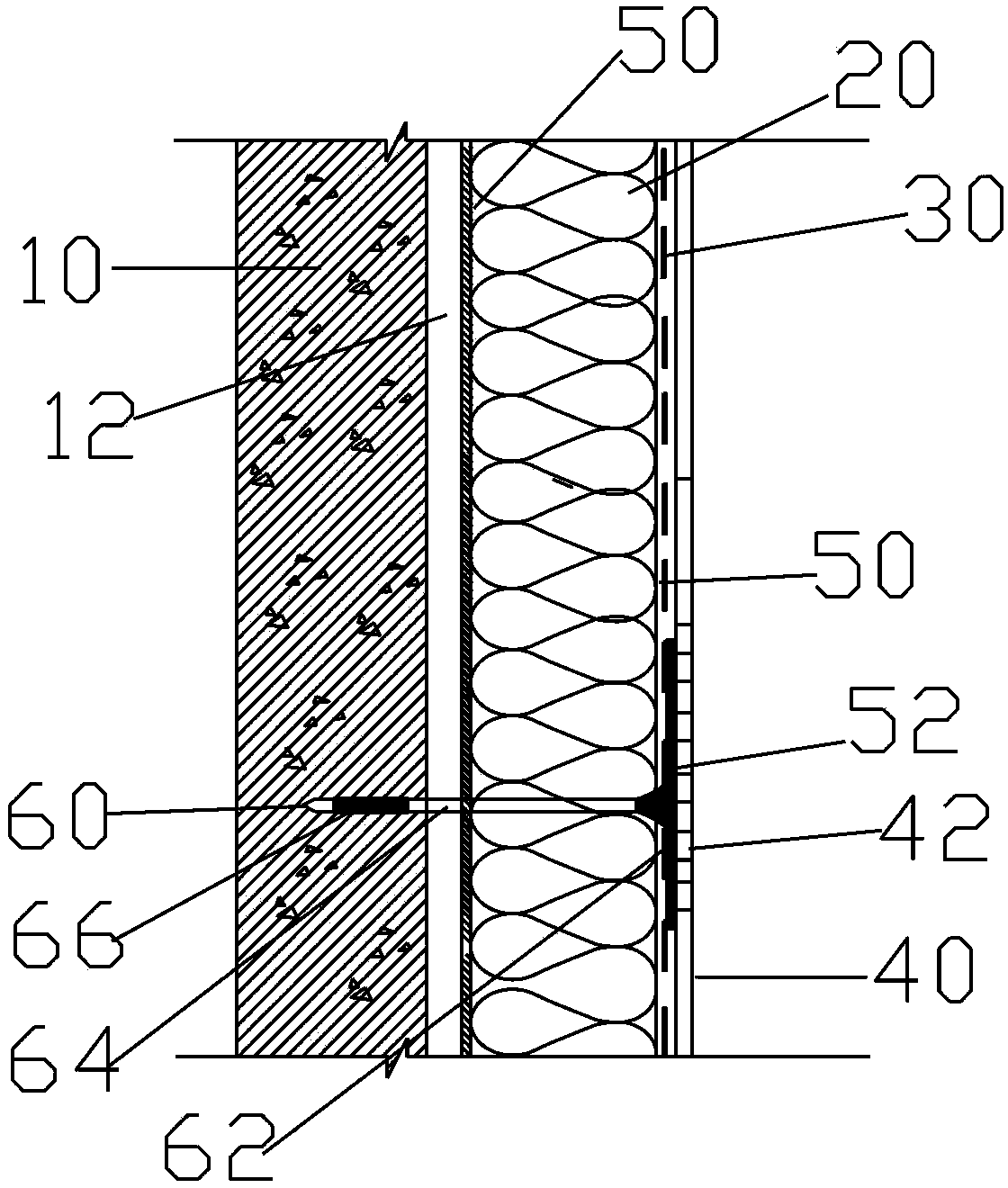

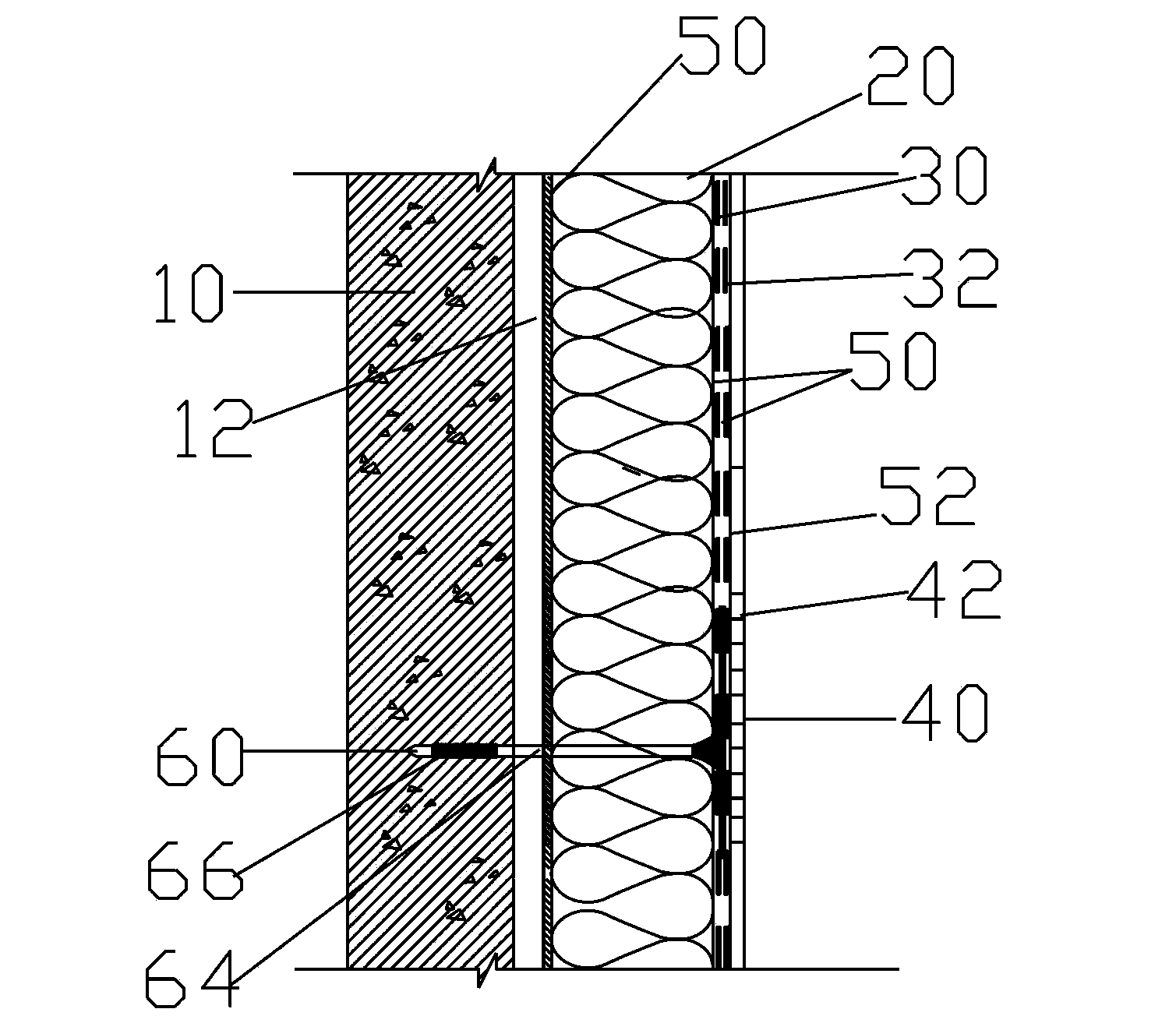

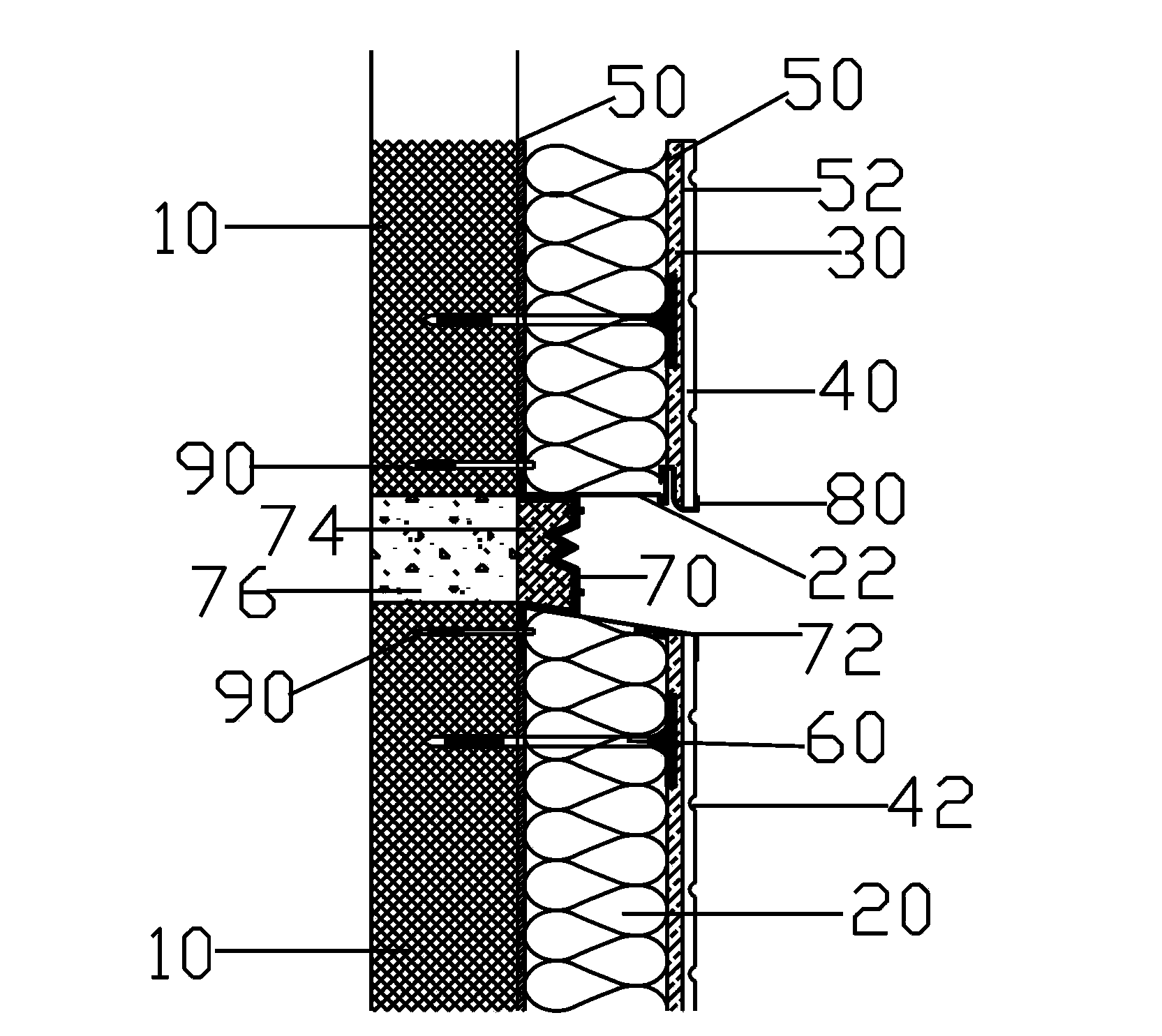

[0029] Example: refer to figure 1 As shown, the present invention provides an embodiment of an exterior wall system with a thermal insulation structure, which is arranged on the leveling layer 12 of the base wall 10, which includes rock wool 20 bonded to the leveling layer 12, bonded to the The protective net 30 on the rock wool 20 , the facing layer 40 arranged on the protective net 30 , and the diffusion fixing device 60 passing through the protective net 30 and the rock wool 20 and fixed to the base wall 10 . Among them, the rock wool 20 is bonded to the base wall 10 through the first layer of glue 50, the rock wool 20 is bonded to the protective net 30 through the second layer of glue 52, and the protective net 30 is passed between the decorative layer 40 and the protective net 30. Glue 52 is fixed. Ventilation holes 22 are provided around the rock wool 20 to allow water vapor to permeate unimpeded and improve the safety of the finish layer 40 . The protective net 30 ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com