A kind of round aluminum phosphate/thermosetting resin composite material and preparation method thereof

A technology of resin composite materials and disc aluminum phosphate, which is applied in the fields of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems that aluminum phosphate is not a flame retardant, and the research and development results of flame retardant have not been reported, and achieve excellent results Effects of thermal stability, good interfacial force, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of disc-shaped aluminum phosphate

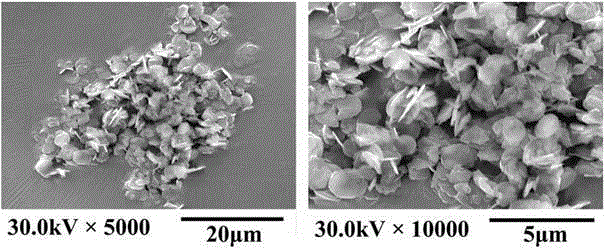

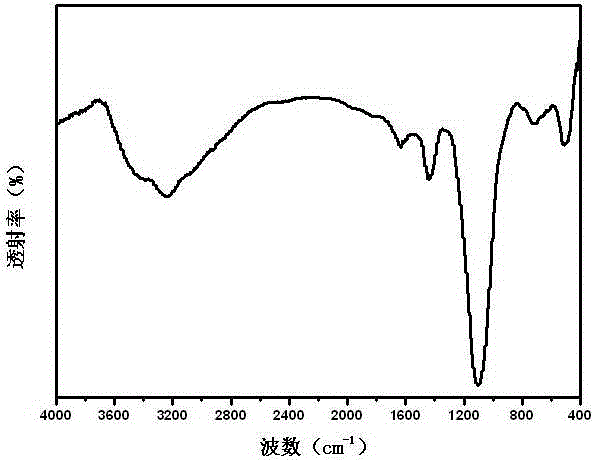

[0035] Under stirring conditions at 80° C., 1 mol of aluminum hydroxide was reacted with 3.5 mol of phosphoric acid for 20 minutes to prepare an aluminum dihydrogen phosphate precursor. In the prepared aluminum dihydrogen phosphate precursor, add 5.5 moles of deionized water to obtain the aluminum dihydrogen phosphate precursor solution; the precursor aluminum dihydrogen phosphate solution is cooled to 0 ° C, and the aluminum dihydrogen phosphate precursor solution is The ammonia solution with a concentration of 8 mol / liter was added dropwise to the solution until the pH value of the solution was 4; it was continued at 0°C for 9 hours; after the reaction was completed, washing and suction filtration were performed to remove impurities to obtain disc-shaped aluminum phosphate, with a yield of 90.0%. Synthetic reaction formula, scanning electron microscope, infrared spectrum, X-ray diffraction spectrum of this disc-shape...

Embodiment 2

[0060] 1. Preparation of disc-shaped aluminum phosphate

[0061] Under stirring conditions at 40°C, 0.5 mol of alumina was reacted with 4.0 mol of phosphoric acid for 20 minutes to obtain an aluminum dihydrogen phosphate precursor; 17 moles of deionized water were added to the prepared aluminum dihydrogen phosphate precursor, Obtain the aluminum dihydrogen phosphate precursor solution; cool the aluminum dihydrogen phosphate precursor solution to 20°C; drop 8.0 mol / liter of ammonia solution into the solution to adjust the pH of the solution to 6, and keep it warm at 20°C for 10 hours; after the reaction , washed, and suction filtered to remove impurities to obtain disc-shaped aluminum phosphate with a diameter of 1.1 μm and a yield of 85.0%.

[0062] 2. Preparation of Flame Retardant Disc Aluminum Phosphate / Bismaleimide Resin Composite

[0063] Weigh 56.8g of N,N'-4,4'-diphenylmethane bismaleimide and 43.2g of O,O'-diallyl bisphenol A in a beaker, and mechanically stir at 135°...

Embodiment 3

[0065] 1. Preparation of disc-shaped aluminum phosphate

[0066]Under stirring conditions at 50°C, react 1 mol of aluminum nitrate with 3.8 mol of sodium dihydrogen phosphate for 10 minutes to obtain an aluminum dihydrogen phosphate precursor; add 8.5 moles of deionized water to obtain an aluminum dihydrogen phosphate precursor solution; cool the aluminum dihydrogen phosphate precursor solution to 10° C.; add 6 mol / liter of ammonia solution dropwise to the solution until the pH of the solution is 6, and keep warm at 15° C. for 8 hours; After the reaction, wash and filter with suction to remove impurities to obtain disc-shaped aluminum phosphate with a diameter of 1.3 μm and a yield of 92.0%.

[0067] 2. Preparation of Flame Retardant Disc Aluminum Phosphate / Cyanate Resin Composite

[0068] Weigh 60g of bisphenol A type cyanate in a beaker and stir mechanically at 150°C until the cyanate is completely dissolved to obtain a clear liquid; add 15g of the disc-shaped aluminum phos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com