Method for recycling reclaimed water in circulating cooling water system

A technology for circulating cooling water and reclaimed water, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as pipeline corrosion, reduce difficulty and reduce secondary pollution The effect of low risk and fouling risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

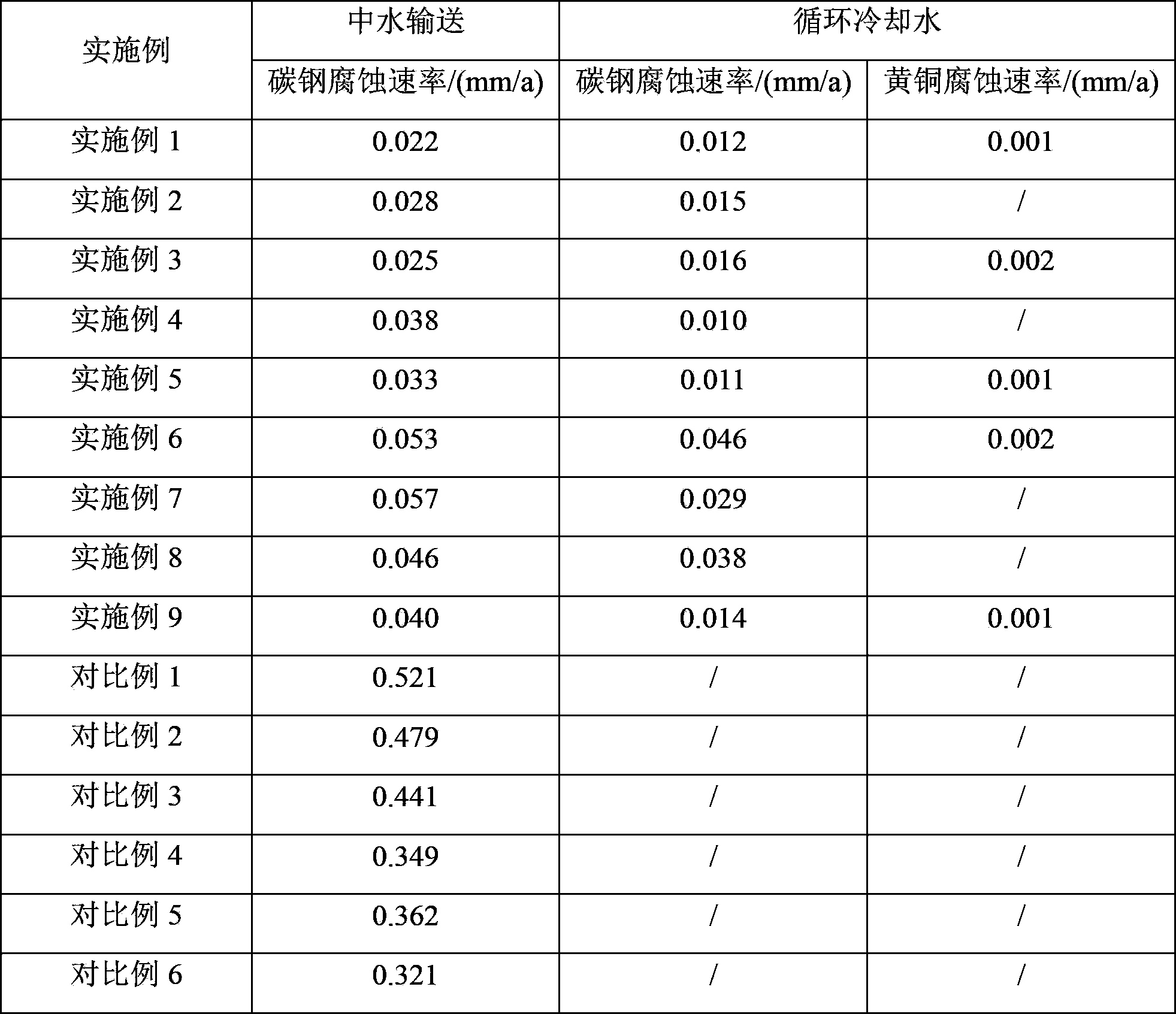

Examples

Embodiment 1

[0047] Take 1# reclaimed water as the test water, add quicklime to it, and calculate per liter of reclaimed water, quicklime (as CaCO 3 The input amount is 40mg / L, and the softened reclaimed water is obtained through solid-liquid separation. Add anhydrous sodium borate to the softened reclaimed water, so that the concentration of anhydrous sodium borate (calculated as B) in the softened reclaimed water is 140mg / L, and conduct the corrosion evaluation test of reclaimed water pipeline transportation. Concentrate the above-mentioned reclaimed water by 3 times, and simulate the state where the reclaimed water added with the aforementioned corrosion inhibitor in the production site is added to the recirculating cooling water in the recirculating cooling water system as replenishment water of the recirculating cooling water to obtain simulated recirculating cooling water. Add polymaleic acid (Changzhou Wujin Water Quality Stabilizer Factory, Nanjing Institute of Chemical Technology,...

Embodiment 2

[0049] Take 2# reclaimed water as the test water, add slaked lime thereinto, in terms of per liter of reclaimed water, the slaked lime in reclaimed water (as CaCO 3 The input amount is 110mg / L, and the softened reclaimed water is obtained through solid-liquid separation. Sodium borate decahydrate was added to the softened reclaimed water so that the concentration of sodium borate decahydrate (calculated as B) in the softened reclaimed water was 70 mg / L, and the corrosion evaluation test for reclaimed water pipeline transportation was carried out. Concentrate the above-mentioned reclaimed water by 4.5 times, and simulate the state where reclaimed water added with the aforementioned corrosion inhibitor in the production site is added to the recirculating cooling water in the recirculating cooling water system as replenishment water for recirculating cooling water to obtain simulated recirculating cooling water. Add polyepoxysuccinic acid (Changzhou Global Chemical Co., Ltd., bra...

Embodiment 3

[0051] Take 3# reclaimed water as the test water, add slaked lime thereinto, in terms of per liter of reclaimed water, the slaked lime in reclaimed water (as CaCO 3 The input amount is 220mg / L, and the softened reclaimed water is obtained through solid-liquid separation. Add anhydrous potassium borate to the softened reclaimed water, so that the concentration of anhydrous potassium borate (calculated as B) in the softened reclaimed water is 120mg / L, and conduct corrosion evaluation test for reclaimed water pipeline transportation. Concentrate the above-mentioned reclaimed water by 2.5 times, and simulate the state where reclaimed water added with the aforementioned corrosion inhibitor in the production site is added to the recirculating cooling water in the recirculating cooling water system as replenishment water for recirculating cooling water to obtain simulated recirculating cooling water. Add acrylic acid-hydroxypropyl acrylate-2-acrylamide-2-methylpropanesulfonic acid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com