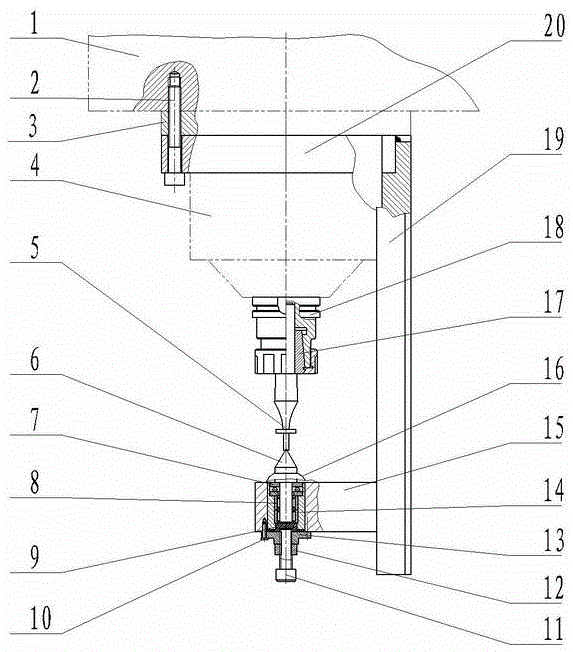

Fixture for NC Milling Crankshaft Keyway

A CNC milling and crankshaft key technology, applied in clamping, clamping devices, manufacturing tools, etc., can solve the problems of difficult to guarantee the machining accuracy of ordinary milling machines, environmental pollution around the machine tool, unstable machining quality, etc., to save direct production costs , the production environment is good, the effect of saving maneuver time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

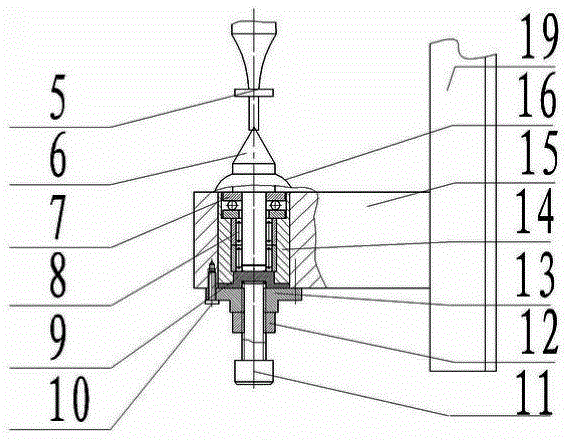

[0019] Such as figure 1 , figure 2 As shown, the milling cutter 5 is clamped on the spindle bearing seat 4 of the end milling head with a circlip 17 and a collet 18. Circular transition fit can play the role of pin hole positioning, ensuring the coaxiality accuracy of the center axis of the fixture and the spindle of the end milling head; Close on the bed 1 of the end milling head, the flange connecting sleeve 20 is welded on the fixed bracket 19, which ensures the firmness of the milling cutter installation, and ensures that the fixed bracket 19 is directly behind the CNC end milling machine table; the milling cutter 5 according to According to the needs of crankshaft processing, it is designed as a special milling cutter to ensure that it does not interfere with the journal of the crankshaft keyway when milling the keyway. When the milling cutter 5 is clamped by the circlip 17, there is a stepped shaft for positioning to ensure that the top 6 is tight. , the axial positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com