A Welding Method for Reducing Porosity in Fusion Welding of Die Casting Magnesium Alloy

A welding method and fusion welding technology, applied in welding/welding/cutting items, welding equipment, welding medium, etc., can solve the problem of less research on porosity reduction/elimination measures, and achieve low implementation cost, improved welding quality, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

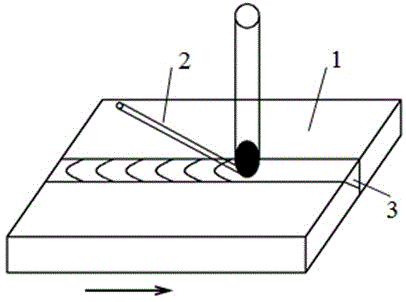

Method used

Image

Examples

Embodiment 1

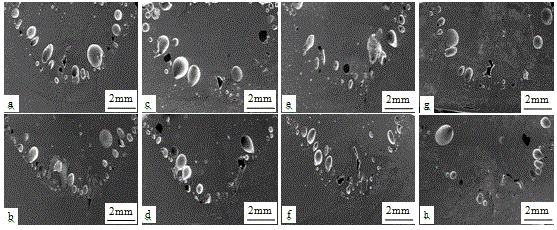

[0025] Embodiment 1: Based on the above specific implementation method, the welding wire material selected is an extruded AZ61 magnesium alloy for welding. The specific composition of the welding wire is as follows: Al6.45%, Zn0.80%, Si0.07%, Mn0.24%, and the balance is Mg. Two weld cross-sections obtained by intercepting typical parts of the weld after welding are shown in figure 2 As shown in (a) and (b), there are more bubbles and poor welding quality.

Embodiment 2

[0026] Example 2: Based on the above specific implementation method, the selected welding wire material is an extruded AZ61 magnesium alloy, mixed with a small amount of neodymium-rich rare earth elements, and the specific components of the welding wire are taken in the following mass percentages: Al6.37%, Zn0.7 %, Si0.04%, Mn0.15%, Nd1.00%, La0.2%, and the balance is Mg. Two weld cross-sections obtained by intercepting typical parts of the weld after welding are shown in figure 2 As shown in (c) and (d), the porosity is reduced relative to (a) and (b), and the welding quality is improved.

Embodiment 3

[0027] Example 3: Based on the above specific implementation method, the selected welding wire material is an extruded AZ61 magnesium alloy mixed with a small amount of neodymium-rich rare earth elements. The specific components of the welding wire are the following mass percentages: Al6.26%, Zn0.73 %, Si0.06%, Mn0.26%, Nd2.00%, La0.4%, and the balance is Mg. Two weld cross-sections obtained by intercepting typical parts of the weld after welding are shown in figure 2 As shown in (e) and (f), the porosity is reduced again relative to figures (c) and (d), and the welding quality is further improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com