Method for machining butt joints with lock bottoms based on electronic beam welding

An electron beam welding and butt joint technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of insufficient size, large welding deformation of parts, difficult to eliminate deep pores, etc., and achieve high quality The effect of welding level, avoiding the problem of welding seam porosity, and ensuring the pass rate of one-time inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

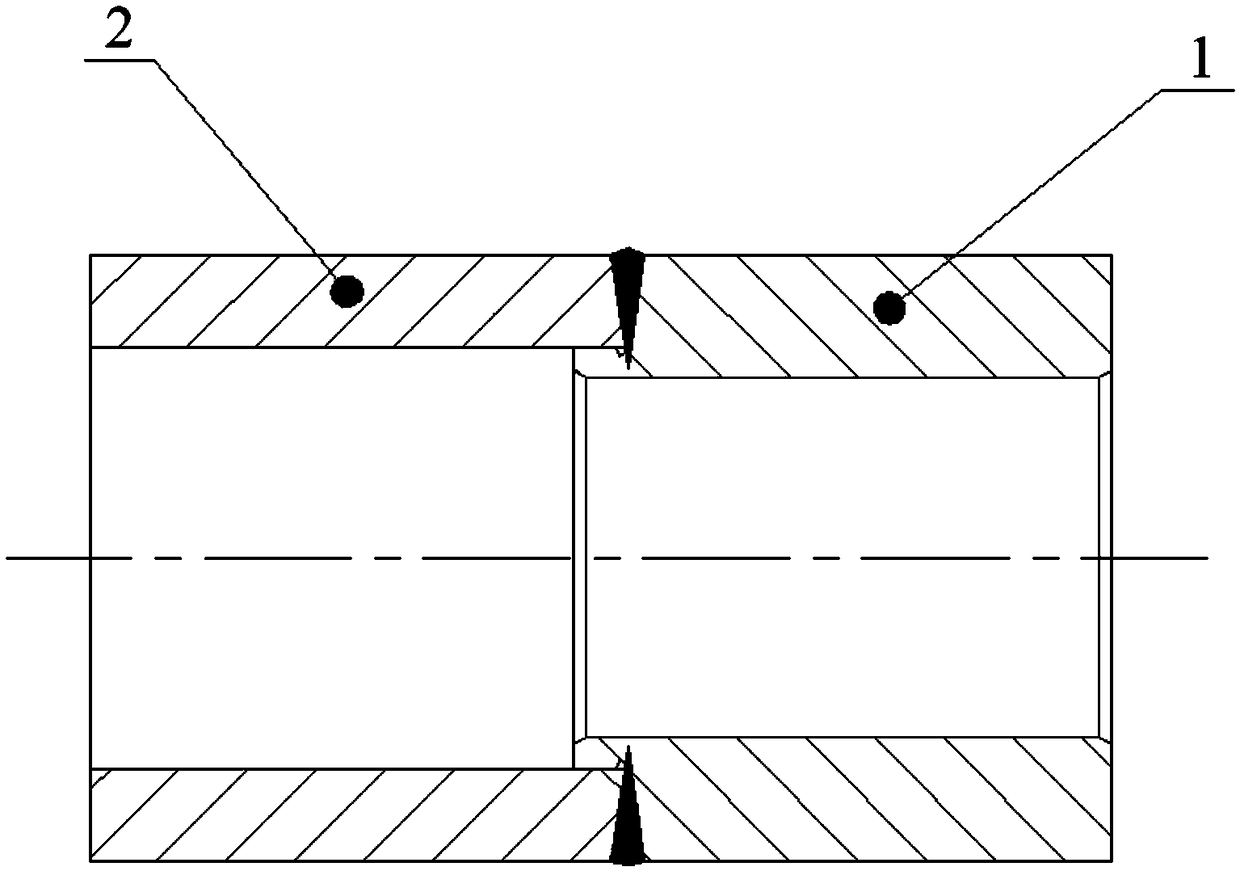

[0026] see Figure 4 ~ Figure 6 , Figure 5 Yes Figure 4 In the enlarged view at A, a method for processing a butt joint with a bottom lock based on electron beam welding provided by an embodiment of the present invention includes the following steps:

[0027] S1, pre-open multiple air outlets on the part with the lock bottom, the multiple air outlets are located at the root of the lock bottom and are evenly distributed, and the air outlets penetrate from one side of the lock bottom to the other side.

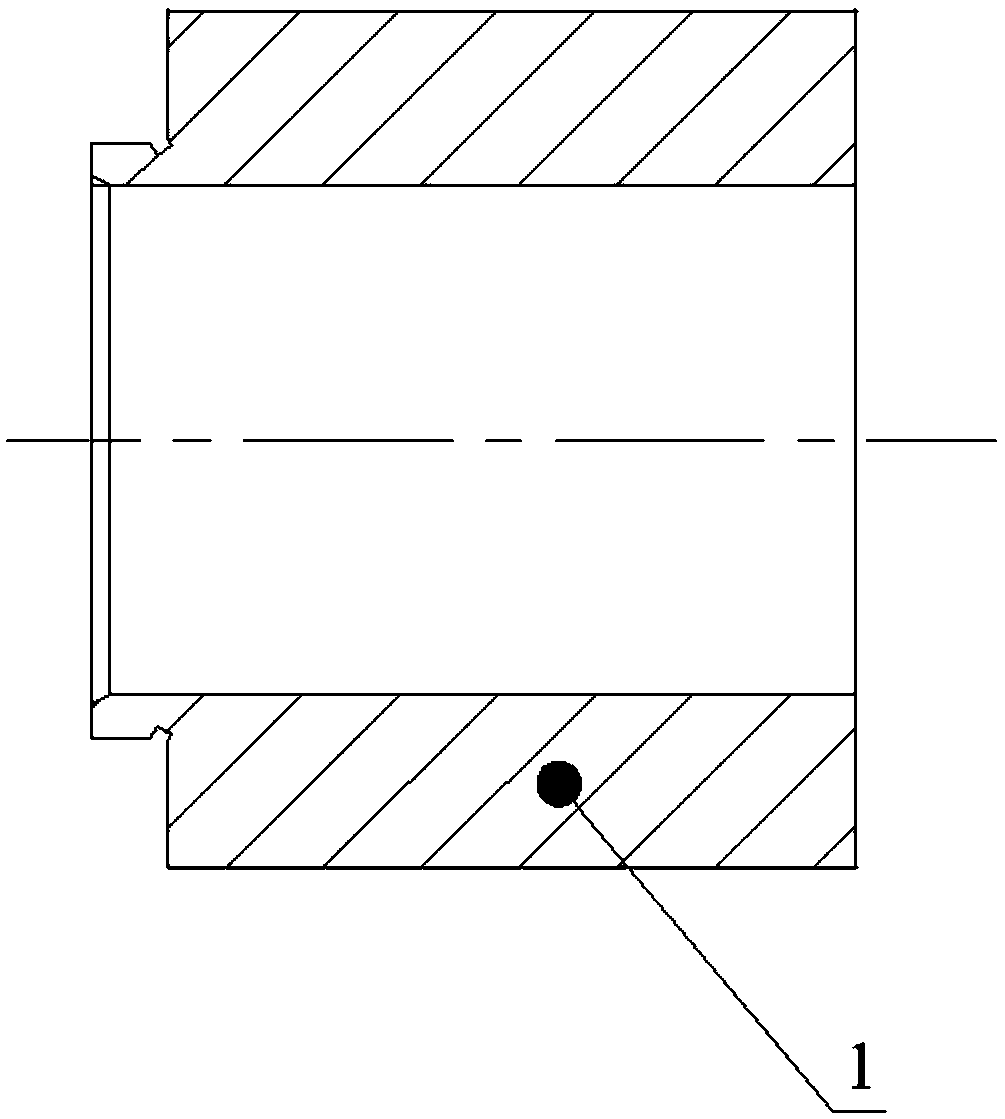

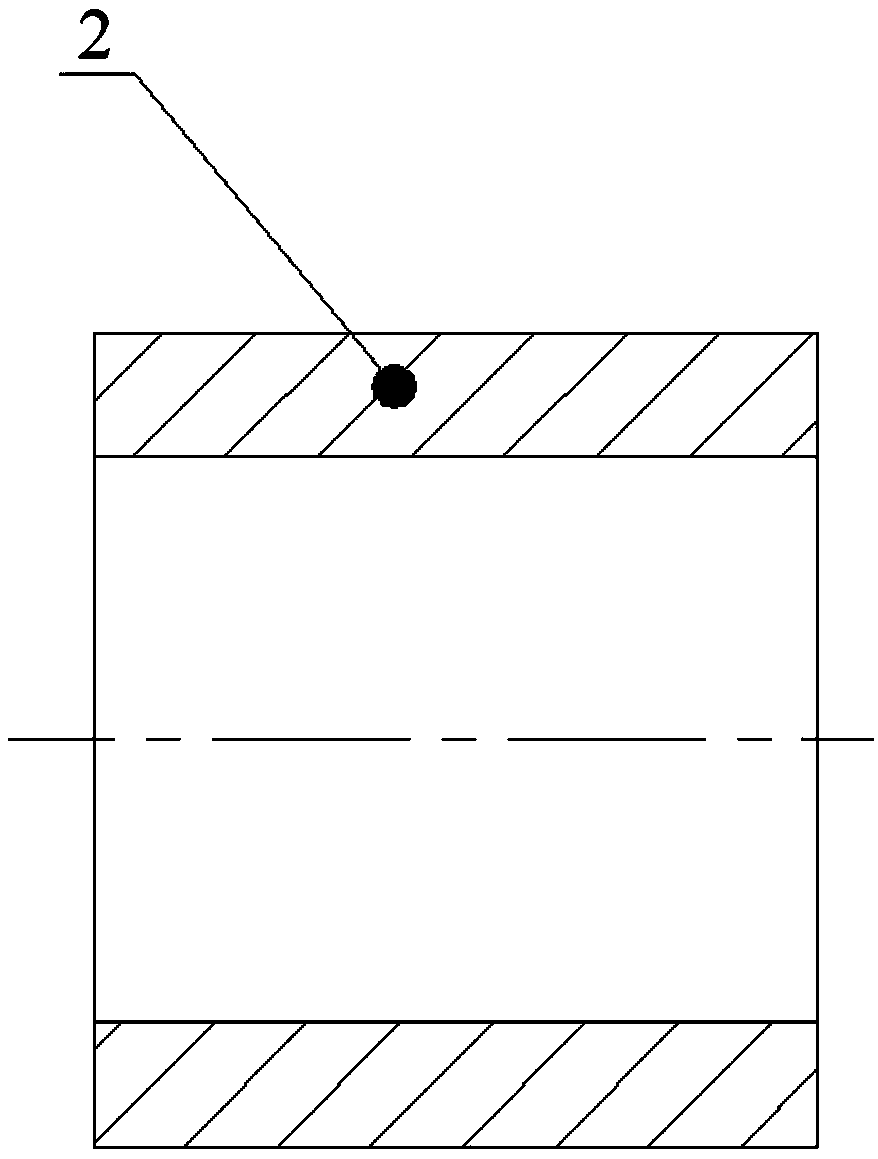

[0028] As shown in the figure, 1 and figure 2 As shown, piece 1 is a part with a bottom lock. Before docking with piece 2, a plurality of air outlet holes 11 are opened on piece 1 in advance, as Figure 4 and Figure 5 As shown, the opening position of the air outlet hole 11 is the root of the lock bottom, and the air outlet hole 11 pen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com