Biodegradable material for preventing postoperative adhesion and preparation method thereof

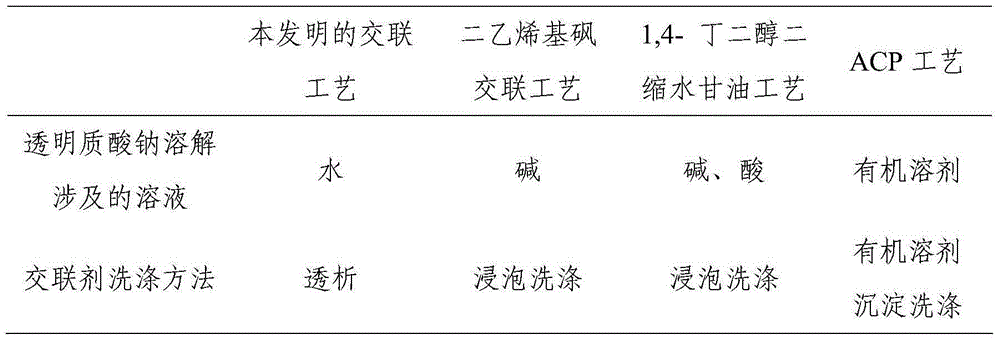

A degradable material and biological technology, applied in surgery, medical science, etc., can solve the problems of long preparation period and complicated operation steps, and achieve the effect of preventing adhesion, good mechanical strength, and no genotoxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Biodegradable material for preventing postoperative adhesions and its preparation

[0027] Include the following steps:

[0028] (1) Sodium hyaluronate with a molecular weight of 2 million Daltons was dissolved in purified water to prepare a solution with a concentration of 2%. Stir to fully dissolve the sodium hyaluronate.

[0029] (2) Slowly add 2-chloro-1-methylpyridinium iodide (CMPI) dropwise to the sodium hyaluronate solution, so that the molar ratio of CMPI to sodium hyaluronate is 1:8, and after fully stirring and mixing, Stand at room temperature for 12h.

[0030] (3) Use dialysis paper to dialyze the mixed solution, and replace the purified water for dialysis regularly.

[0031] (4) Pour the mixed solution into a mold, and vacuum-dry for 24 hours in a temperature-changing environment of 30° C., 40° C., 45° C., and 30° C. to obtain a film-like degradable anti-adhesion material.

Embodiment 2

[0032] Example 2 Biodegradable material for preventing postoperative adhesions and its preparation

[0033] (1) Sodium hyaluronate with a molecular weight of 2 million Daltons was dissolved in purified water to prepare a solution with a concentration of 0.6%. Stir to fully dissolve the sodium hyaluronate.

[0034] (2) Slowly add water-soluble carbodiimide (EDC) dropwise to the sodium hyaluronate solution, so that the molar ratio of EDC to sodium hyaluronate is 1:5, stir and mix well, and let stand at room temperature for 8 hours.

[0035] (3) Dialyze the mixed solution with dialysis paper, and replace the purified water for dialysis every 1 hour. Cumulatively wash 12 times.

[0036] (4) Pour the mixed solution into a mold, freeze at -30° C. for 2 hours, and then dry at 25° C. for 24 hours to obtain a spongy degradable anti-adhesion material.

Embodiment 3

[0037] Example 3 Biodegradable material for preventing postoperative adhesions and its preparation

[0038] (1) Sodium hyaluronate with a molecular weight of 1.6 million Daltons was dissolved in purified water to prepare a solution with a concentration of 2%. Stir to fully dissolve the sodium hyaluronate.

[0039] (2) Slowly add 2-chloro-1-methylpyridinium iodide (CMPI) dropwise to the sodium hyaluronate solution, so that the molar ratio of CMPI to sodium hyaluronate is 1:16, and after fully stirring and mixing, Stand at room temperature for 12h.

[0040] (3) Dialyze the mixed solution with dialysis paper, replace the purified water for dialysis every 2 hours, and wash 5 times cumulatively.

[0041] (4) Pour the mixed solution into a mold, and vacuum-dry it in an environment of 40° C. for 24 hours to obtain a transparent film-like degradable anti-adhesion material.

[0042] The self-crosslinking biodegradable biomaterial prepared in Examples 1-3 has good mechanical strength, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com