Faraday apparatus for measuring beam

A measuring device, Faraday cup technology, applied in the direction of measuring device, radiation measurement, X/γ/cosmic radiation measurement, etc., can solve problems such as difficult to guarantee sealing performance, heat generation, inaccurate test results, etc., and achieve magnetic circuit design Reasonable, simple wiring, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

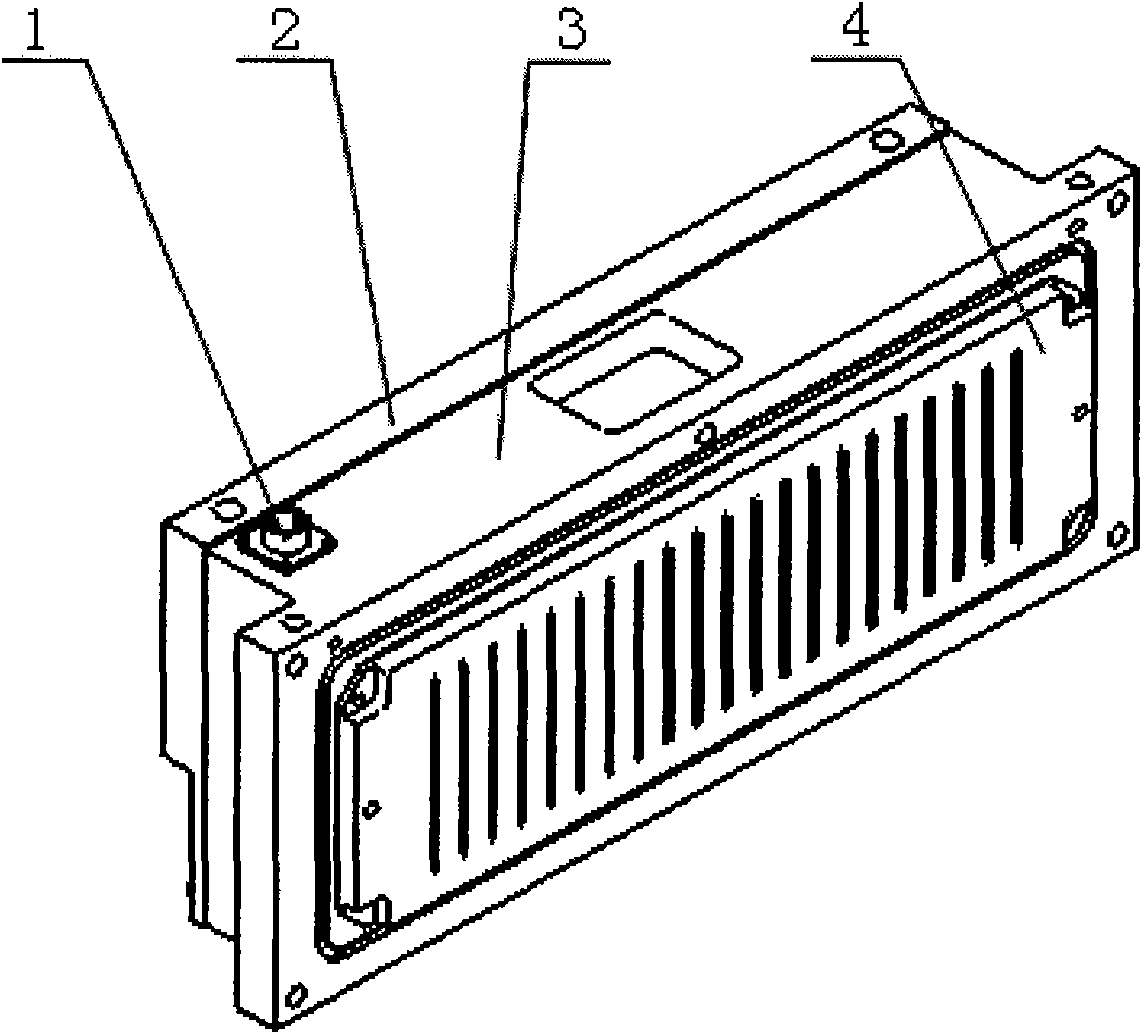

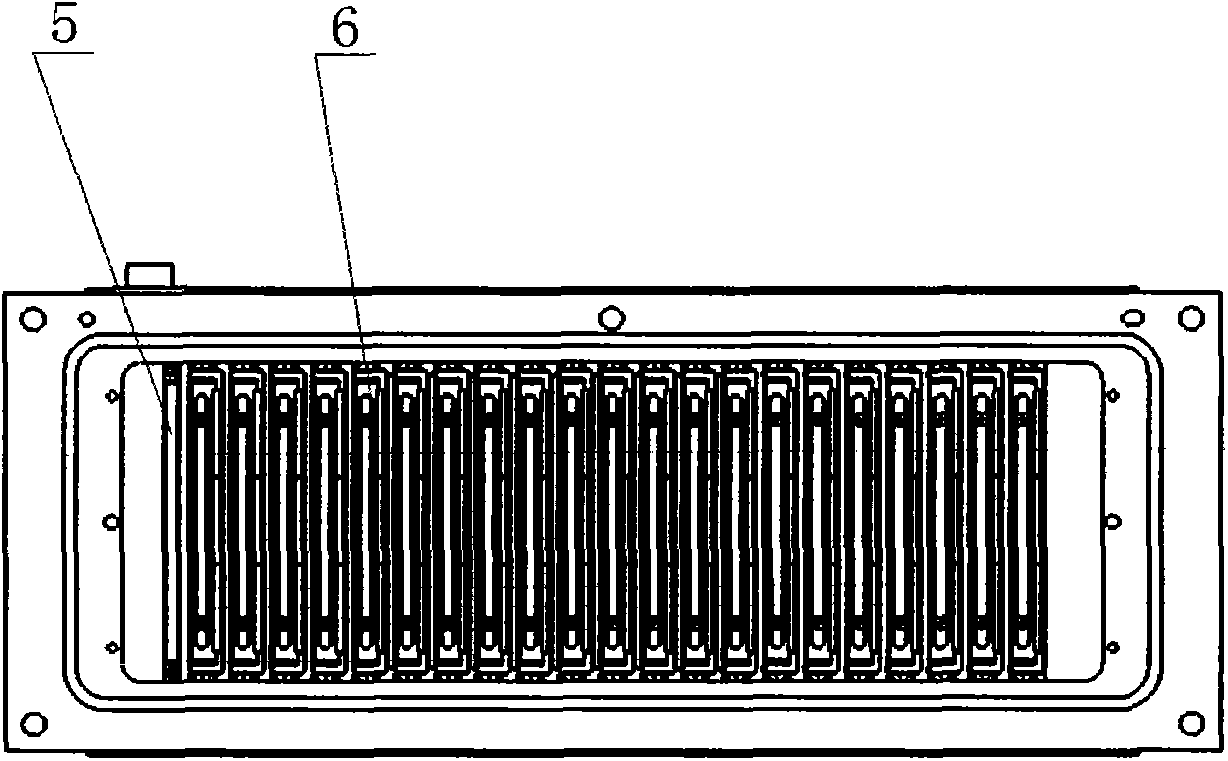

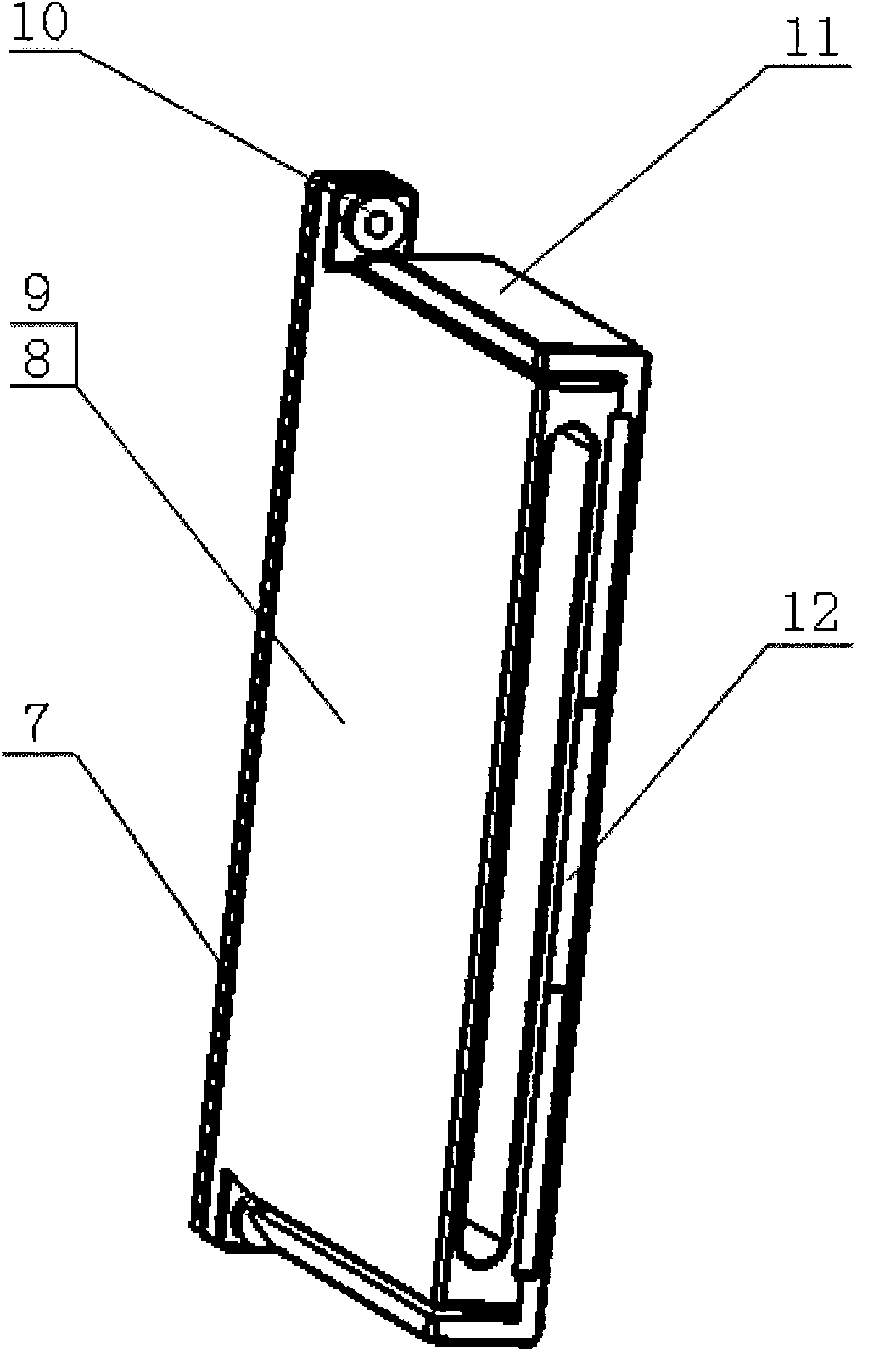

[0023] Attached below figure 1 , attached figure 2 And attached image 3 The present invention is further introduced, but not as a limitation to the present invention. The scope of the invention is limited only by the scope of the appended claims.

[0024] One embodiment of the present invention is as figure 1 , figure 2 and image 3 shown.

[0025] see figure 1 , figure 2 and image 3 , a beam Faraday measuring device, comprising: a sealed socket (1), a Faraday cup mounting plate (2), a Faraday collection frame (3), a graphite baffle (4), a magnetic plate (5), a miniature Faraday cup (6), where if image 3 As shown, the miniature Faraday cup (6) is composed of an insulating gasket (7), a Faraday cup body (8), graphite at the bottom of the cup (9), a small insulating gasket (10), a magnet mounting plate (11) and a suppression magnet (12). A total of 21 of the miniature Faraday cups (6) are installed side by side with the magnetic guide plate (5) on the Faraday c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com