Improved gradient freeze GaAs single crystal growing method

A gradient solidification, improved technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as cumbersome

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

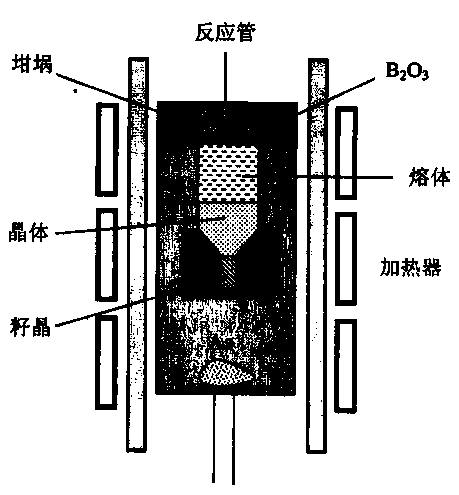

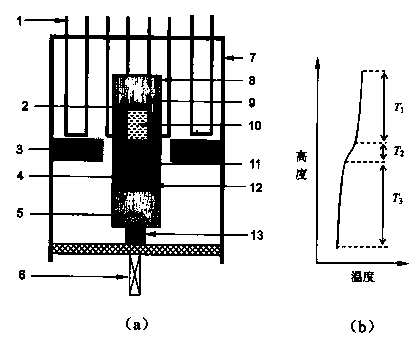

Method used

Image

Examples

Embodiment 1

[0020] Growth of undoped GaAs single crystals. Put 4.0 kg of high-purity GaAs polycrystalline raw material into a PBN crucible with a diameter of 4 inches, and a seed crystal with a orientation and a diameter of 10 mm was placed on the bottom of the crucible in advance. Then the crucible was placed in a crystal growth furnace, the furnace temperature was controlled at 1255°C, and seed growth was started after the temperature was kept constant for 12 hours. The crystal growth temperature gradient was 7°C / cm, and the growth cycle was 7 days. After the growth, anneal at 850°C for 10 hours in a constant temperature zone, and slowly cool down to room temperature to obtain GaAs crystals with bright and non-wetting surfaces.

Embodiment 2

[0022] Growth of low Si-doped GaAs single crystals. 3.8 kg of high-purity GaAs polycrystalline raw material and 55 mg of Si were mixed into a PBN crucible with a diameter of 4 inches, and a seed crystal with a diameter of 12 mm and a orientation was placed at the bottom of the crucible. Put the PBN crucible into the crystal growth furnace, control the temperature of the furnace at 1255°C, and start the inoculation growth after 12 hours of constant temperature. The crystal growth temperature gradient was 10°C / cm, and the growth cycle was 7 days. After the growth is completed, anneal at 900°C for 12 hours in a constant temperature zone, and slowly cool down to room temperature to obtain a 4-inch low-Si-doped GaAs crystal with a bright and non-wetting surface.

Embodiment 3

[0024] Growth of heavily Si-doped GaAs single crystals. 3.5 kg of high-purity GaAs polycrystalline raw material was mixed with 80 mg Si and placed in a 4-inch-diameter PBN crucible. A -oriented seed crystal with a diameter of 10 mm was placed at the bottom of the crucible. Put the PBN crucible into the crystal growth furnace, control the temperature of the furnace at 1260°C, and start the inoculation growth after 12 hours of constant temperature. The crystal growth temperature gradient was 15°C / cm, and the growth cycle was 7 days. After the growth is completed, anneal at 950°C for 12 hours in a constant temperature zone, and slowly cool down to room temperature to obtain a 4-inch heavily Si-doped GaAs crystal with a bright and non-wetting surface.

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com