A method for surface modification of metal materials by atmospheric pressure cooling plasma jet

A technology of cold plasma and metal materials, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve low cost, improve hydrophilicity, and increase surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

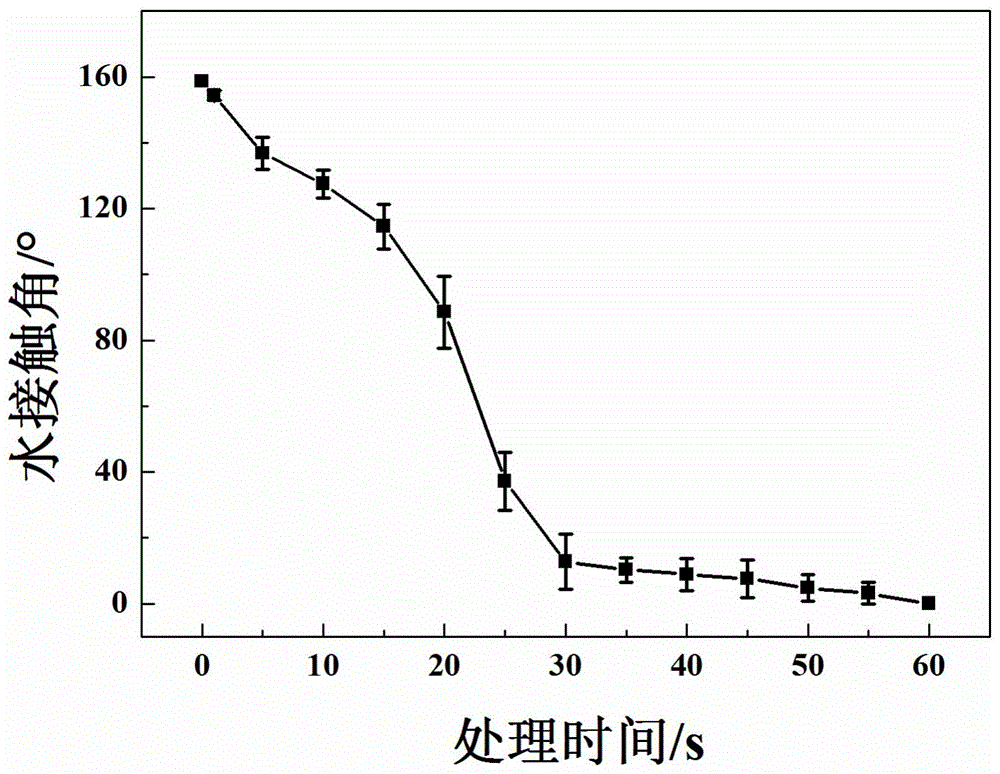

[0016] The surface modification of superhydrophobic aluminum by atmospheric pressure-cooled plasma jet can significantly improve its surface energy and wettability, and realize the transformation from superhydrophobic to superhydrophilic.

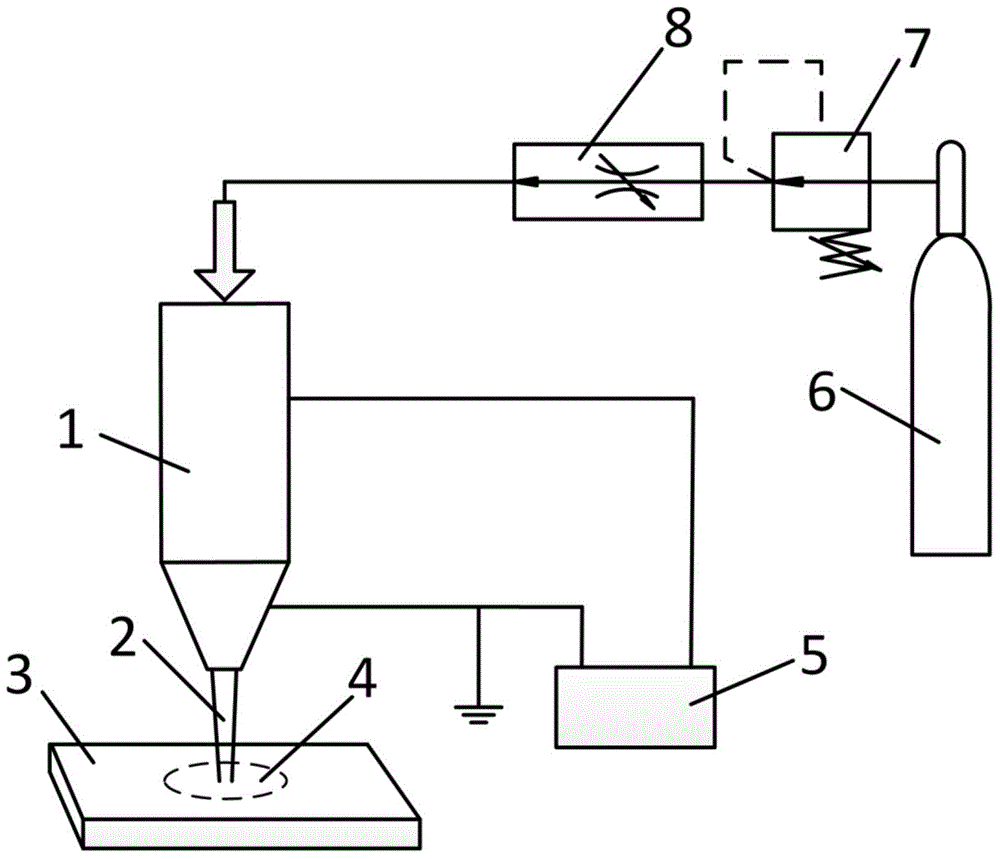

[0017] The atmospheric pressure cooled plasma jet generator 1 uses a bare electrode discharge form, and the cold plasma jet generated by this type of electrode will not cause spark breakdown discharge between the metal and the metal. The two electrodes are respectively a nozzle electrode made of brass and a needle electrode made of tungsten, and the vertical distance between the two electrodes is 2.0 mm. The high-voltage power supply 5 adopts an intermediate-frequency sine wave AC power supply, with an output frequency of 50-120kHz, an output voltage of 0-10kV, and a maximum power of 150W; the high-voltage and low-voltage output terminals of the high-voltage power supply 5 are respectively connected to the central needle electrode and the n...

Embodiment 2

[0019] The surface modification of ordinary aluminum by atmospheric pressure-cooled plasma jet can improve its surface energy and wettability, and make the treated surface have good hydrophilicity.

[0020] The atmospheric pressure cooling plasma jet generator and its discharge parameters are the same as those in Example 1, and the operation steps and methods are also the same. image 3 Shown is the relationship between the water contact angle on the surface of ordinary aluminum and the treatment time of atmospheric pressure-cooled plasma. It can be seen that the original contact angle of the ordinary aluminum surface is about 80°. After the surface is treated with the atmospheric pressure cooling plasma jet, its wettability can be improved, and the contact angle can be reduced to 20° after 90s of treatment. It has good hydrophilicity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com