Preparation method for high fine rubber powder and production line thereof

A high-precision, production line technology, applied in recycling technology, mechanical material recycling, plastic recycling, etc., to achieve the effect of stabilizing physical and chemical properties and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

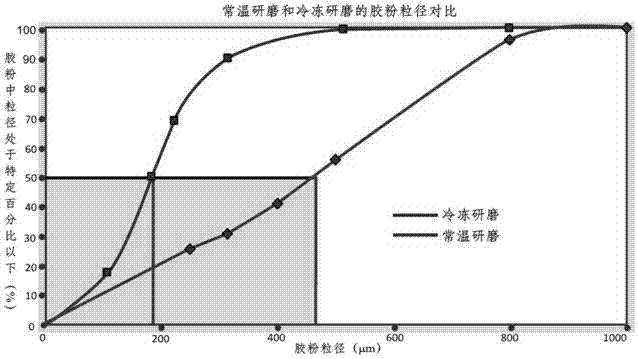

[0062] Example: Freeze Grinding Process

[0063] According to the embodiment of the present invention, the fine grinding system adopts a pressureless design, which is suitable for low temperature grinding.

[0064] material selection

[0065] In terms of materials of construction, unless otherwise specified, all equipment and system elements are preferably fabricated from mild steel. The conveying screw cooler is preferably made of stainless steel, and the grinding elements of the pin mill are preferably made of special steel, which is suitable for low-temperature grinding. The inlet trough is also made of stainless steel.

[0066] Mill noise level

[0067] In terms of the noise level of the mill, without noise protection measures: about 110dB(A). Frequency range 63-16000 Hz, measuring surface-integrated sound pressure level (SPL) according to DIN45635, Part 1, accuracy class 3.

[0068] electrical control

[0069] In terms of electrical control, supply voltage: 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com