Water spraying device for blowing-out of blast furnace

A blast furnace, horizontal technology, applied in the direction of cooling devices, etc., can solve the problems of low heat exchange rate between water and gas, serious environmental pollution, long shutdown time, etc., achieve good atomization effect, low H2 content, and improve heat exchange rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

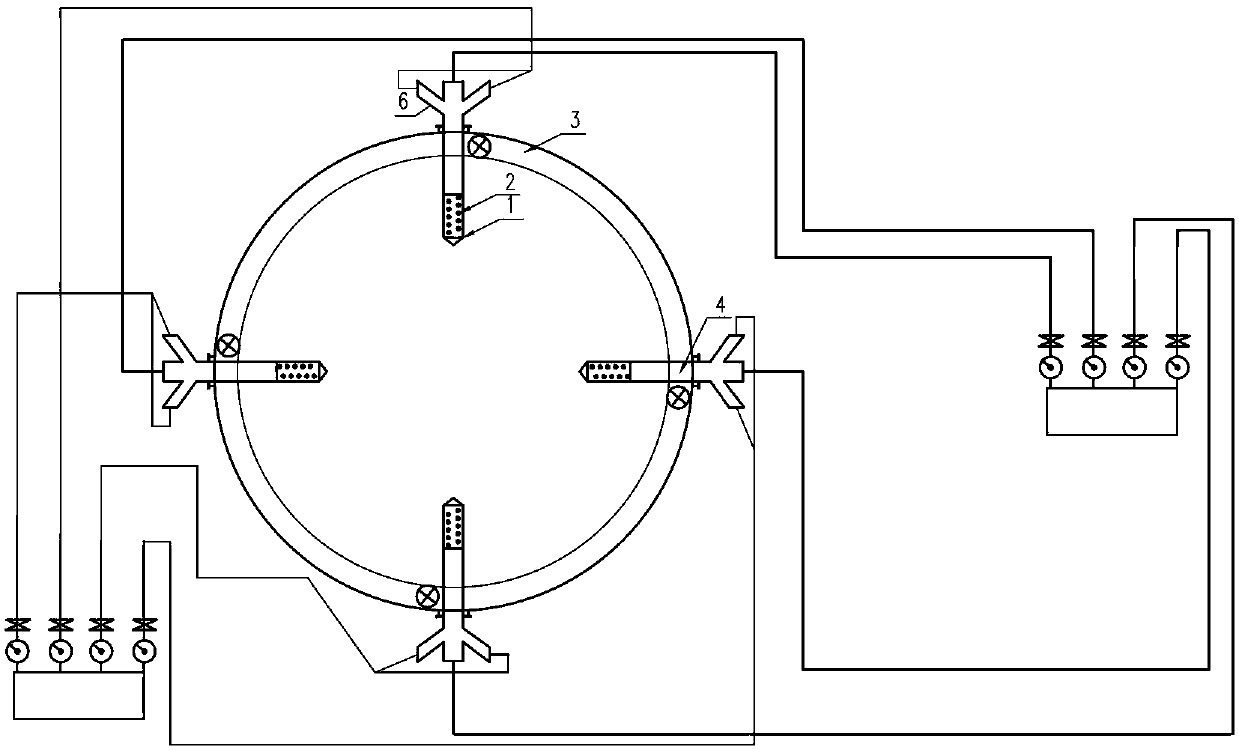

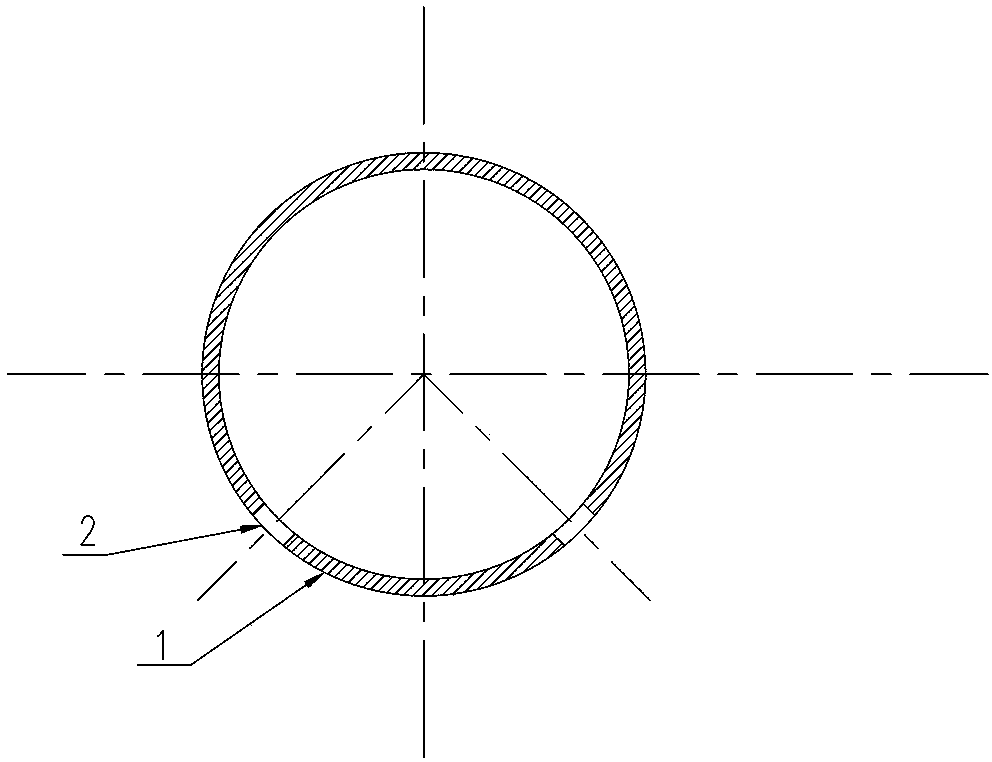

[0018] A blast furnace shut down water fetching device, such as figure 1 , figure 2 As shown, including the gun body 4 with the gun head 1, the gun body 4 is four, and the four gun bodies 4 are centrally symmetrical and horizontally distributed and installed on the furnace shell wall 3 at intervals, and the two sides of the rear end of the gun body 4 are respectively connected with A nitrogen injection pipe 6, each nitrogen injection pipe 6 and the gun body 4 are connected at an angle of 45 degrees, the front end of the gun head 1 is closed, and two rows of spray holes 2 are arranged on the bottom surface of the gun head 1 along its axial direction. Two adjacent rows of nozzle holes 2 are arranged in a misplaced position, and the angle between the two rows of nozzle holes 2 is 90 degrees, such as figure 2 As shown, that is, the angle between the center line of each row of nozzle holes 2 and the vertical line is 45 degrees. The gun body 4 is connected with a high-pressure w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com