Antibacterial reinforced nylon material and preparation method thereof

A technology of nylon and compound antibacterial agent, which is applied in the field of preparation of antibacterial reinforced nylon materials, which can solve the problems of short validity period, inability to use broad spectrum and long-term effect, and limited antibacterial effect of natural antibacterial agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

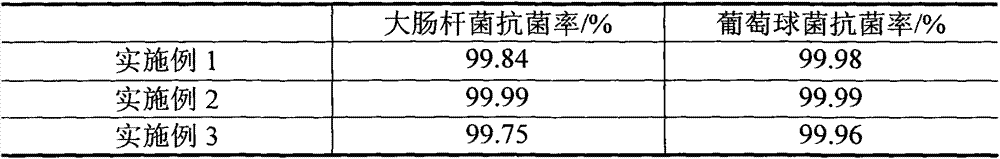

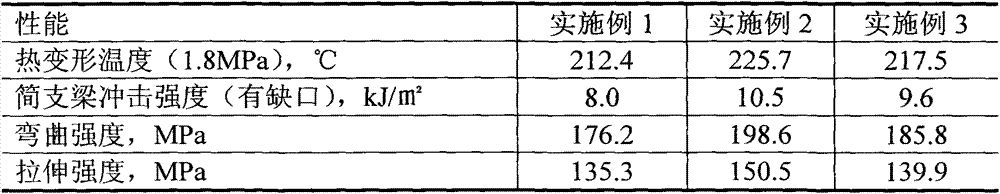

Examples

Embodiment 1

[0015] 1. Take by weighing 180 grams of Pr-Ag antibacterial white carbon black, 30 grams of nano-titanium dioxide, and 800 grams of nylon 66 raw material. %; use a mixer to mix the coupling agent and antibacterial agent first, then add other materials and mix evenly; carry out extrusion granulation at 220°C to 260°C and a speed of 250 to 400r / min to prepare antibacterial nylon masterbatch.

[0016] 2. Weigh 60 parts of nylon 66 plastic, 10 parts of alkali-free short glass fiber, 0.1 part of antioxidant, 0.1 part of lubricant, and 0.1 part of coupling agent. The material is extruded and granulated in a twin-screw extruder, the temperature of each section of the extruder is controlled at 220°C to 260°C, and the rotation speed is 250 to 400r / min to obtain reinforced nylon.

[0017] 3. Weigh the two materials according to the ratio of antibacterial nylon masterbatch (mass): reinforced nylon (mass) = 1:30; place the weighed two materials in a disperser and mix them evenly to obtain...

Embodiment 2

[0020] 1. Take by weighing 180 grams of Pr-Ag antibacterial white carbon black, 30 grams of nano-titanium dioxide, and 800 grams of nylon 66 plastics. The coupling agent is a silane coupling agent and a titanate coupling agent, and the addition is 0.5% of the weight of the antibacterial agent. %; use a mixer to mix the coupling agent and antibacterial agent first, then add other materials and mix evenly; extrude and granulate at 220°C to 260°C at a speed of 250 to 400r / min to prepare antibacterial nylon masterbatch.

[0021] 2. Weigh 80 parts of nylon 66 plastic, 25 parts of alkali-free short glass fiber, 0.3 part of antioxidant, 0.2 part of lubricant, and 0.3 part of coupling agent. Mix the above raw materials evenly with a mixer, and then extrude and granulate in a twin-screw extruder. The temperature of each section of the extruder is controlled at 220°C to 260°C, and the speed is 250 to 400r / min to obtain reinforced nylon.

[0022] 3. According to the ratio of antibacteria...

Embodiment 3

[0025] 1. Take by weighing 170 grams of Pr-Ag antibacterial white carbon black, 30 grams of nano-titanium dioxide, and 785 grams of nylon 66 plastics. The coupling agent is a silane coupling agent and a titanate coupling agent. %, use a disperser to mix the coupling agent and antibacterial agent first, then add other materials and disperse evenly; then extrude and granulate. Obtain antibacterial nylon masterbatch.

[0026] 2. Weigh 70 parts of nylon 66 plastic, 15 parts of alkali-free short glass fiber, 0.3 part of antioxidant, 0.2 part of lubricant, and 0.1 part of coupling agent. The extruder is extruded and granulated, and the temperature of each section of the extruder is controlled at 220°C to 260°C, and the rotation speed is 250 to 400r / min to obtain reinforced nylon.

[0027] 3. Weigh the two materials according to the ratio of antibacterial nylon masterbatch (mass): reinforced nylon plastic (mass) = 1:25, put the weighed two materials in a disperser and disperse evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com