Interlayer film for laminated glass and laminated glass containing same

A technology of laminated glass and interlayer film, applied in the directions of lamination, layered products, lamination devices, etc., can solve the problems of reduced service life of the release agent, sticking, and difficulty in exhausting and degassing the air of the laminated glass, so as to improve the degassing effect. Gas, avoid ripple phenomenon, improve the effect of manufacturing and processing workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

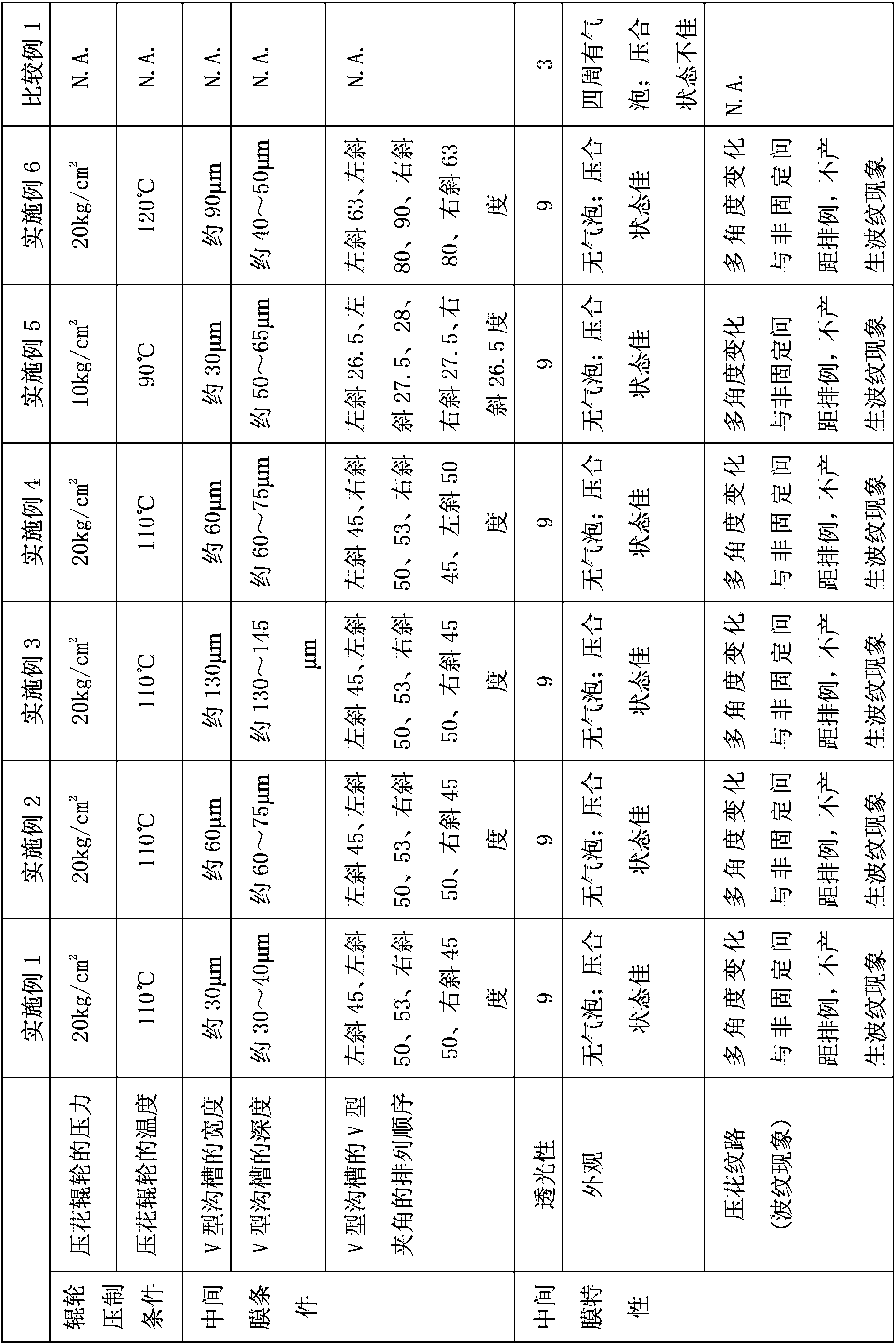

Embodiment 1

[0047] Embodiment 1, preparation of interlayer film A1 for laminated glass of the present invention

[0048] Cut the polyvinyl butyral interlayer film of Production Example 1 into a square of 35 cm×35 cm, preheat the polyvinyl butyral interlayer film to 65 to 75° C., and perform double-sided pressing. The pressing conditions are embossing roller temperature 110°C, pressure 20kg / cm 2 , there are several parallel V-shaped raised line embossing lines on the embossing roller, which are complementary to the line-shaped concave lines that the intermediate film wants to have. The top angle of the V-shaped angle is in the range of 45 degrees to 53 degrees For example, the sequence is left oblique 45 degrees, left oblique 50 degrees, 53 degrees, right oblique 50 degrees, right oblique 45 degrees as a cycle, the height of the apex angle from the roller surface is 50 μm, the width is 50 μm, and the distance between the vertices of adjacent raised lines The multi-angle V-shaped convex li...

Embodiment 2

[0049] Embodiment 2, preparation of interlayer film A2 for laminated glass of the present invention

[0050] The conditions are the same as in Example 1, only the embossing roller is replaced by an embossing roller with several parallel V-shaped embossing lines for embossing, and the apex angle of the V-shaped included angle is 45 degrees to 53 degrees Intervals, the order of sorting is 45 degrees to the left, 50 degrees to the left, 53 degrees, 50 degrees to the right, and 45 degrees to the right. The multi-angle V-shaped convex lines with a distance between the vertices of 600 μm were pressed with the embossing rollers that extruded the interlayer film under the above conditions, that is, the pressing operation was completed, and the interlayer film A2 for laminated glass was obtained.

Embodiment 3

[0051] Embodiment 3, preparation of interlayer film A3 for laminated glass of the present invention

[0052] The conditions are the same as in Example 1, only the embossing roller is replaced by an embossing roller with several parallel V-shaped embossing lines for embossing, and the apex angle of the V-shaped included angle is 45 degrees to 53 degrees Intervals, the order of sorting is 45 degrees to the left, 50 degrees to the left, 53 degrees, 50 degrees to the right, and 45 degrees to the right. The multi-angle V-shaped convex lines with a distance of 600 μm between the vertices were pressed with the embossing rollers that extruded the interlayer film under the above conditions, that is, the pressing operation was completed, and the interlayer film A3 for laminated glass was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle angle | aaaaa | aaaaa |

| Vertex angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com