Modified polyvinyl alcohol, preparation method and use thereof

A polyvinyl alcohol and modification technology, applied in the field of polymer chemistry, can solve the problems that the absorption capacity of the plasticizer cannot reach the ideal, the characteristics of the auxiliary dispersant cannot be fully exerted, and the effect of the auxiliary dispersant cannot be fully exerted. effect of reducing the number of fish eyes, excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Copolymerize 12 parts of allyl polyoxyethylene ether with an average added mole number of ethylene oxide of 10 and 100 parts of vinyl acetate in 150 parts of methanol solvent in the presence of 2.1 parts of AIBN. The polymerization temperature is 60°C. When the polymerization reaction is over, switch to blow out the residual single to obtain the comonomer, take a part of the comonomer and adjust it into a methanol solution with a concentration of 40wt%, and carry out alcoholysis with a sodium hydroxide methanol solution with a concentration of 40g / L to obtain the molecule Modified polyvinyl alcohol containing oxyalkylene groups in the chain.

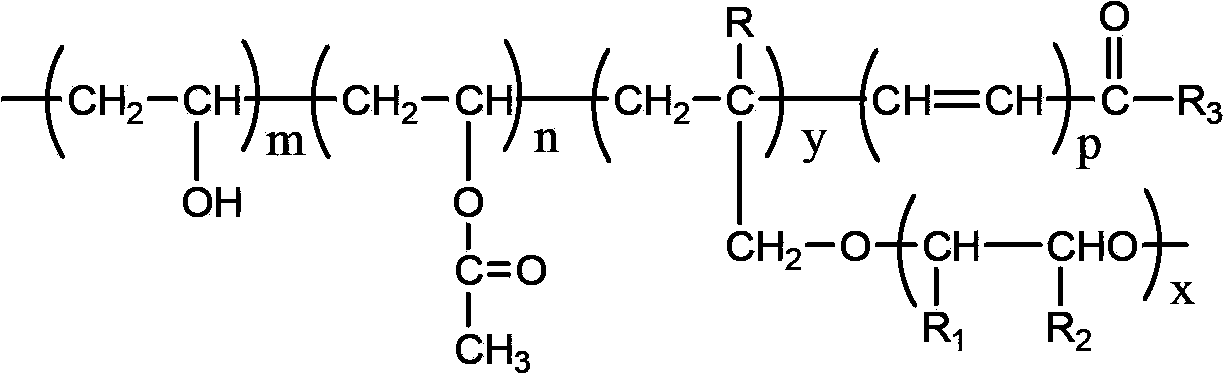

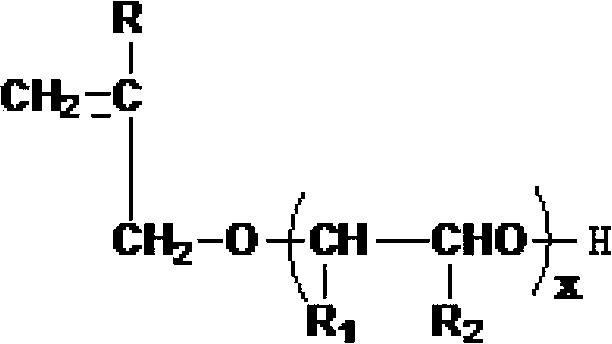

[0025] In order to analyze and confirm the structural formula of the obtained modified polyvinyl alcohol, we have carried out the following detection to the polymer synthesized in Example 1:

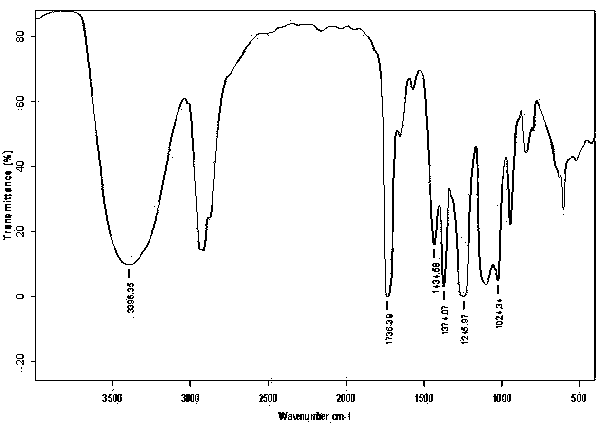

[0026] 1. Infrared qualitative analysis

[0027] Firstly, after air-drying the film of the obtained product, the TENSOR TMSeries FT-IR (l...

Embodiment 2

[0073] The modified polyvinyl alcohol of the present invention is made into the use of aqueous solution assistant dispersant:

[0074] Usually, the water-based auxiliary dispersant of the present invention and other dispersion stabilizers are added into water to disperse the vinyl monomers in it, and carry out polymerization in the presence of an oil-soluble initiator. Such other dispersion stabilizers include methylcellulose, hydroxypropylcellulose, derivatives of hydroxypropylmethylcellulose and cellulose, gelatin or water-soluble polymers such as polyvinyl alcohol and polyvinylpyrrolidone, among which Polyvinyl alcohol with an alcoholysis degree of 68-88mol% and a polymerization degree of 500-2500 is most suitable for use. As for the type of dispersant, the weight ratio range of the added amount of the dispersion stabilizer and the auxiliary dispersant aqueous solution should be 95 / 5-20 / 80, preferably 80 / 20-30 / 60. The aqueous solution of the auxiliary dispersant can be add...

Embodiment 3-9

[0100] Embodiment 3-9, comparative example 1-4

[0101] Using the relevant parameters described in the following tables 1 and 2 and in combination with the conventional production process, according to the preparation method of Examples 1 and 2, the aqueous solution of polyvinyl alcohol auxiliary dispersant and the polyvinyl chloride particle product are prepared, as shown in Table 1. ,Table 2.

[0102] Table 1

[0103]

[0104] Note: A in the table 3 ~A 9 : Specifically: A 3 : Acryl polyether (APEG)-500, A 4 : APEG-600, A 5 .: APEG-300, A 6 : Polyoxyethylene (methyl) allyl ether, A 7 : Isobutylene polyoxyethylene ether, A 8 .: Polyoxypropylene allyl ether, A 9 : polyoxypropylene (meth)propenyl ether; --: no modified monomer added; A: dodecyl mercaptan; B: SMAS; C: itaconic acid.

[0105] Table 2

[0106]

[0107] In addition to the above eight modified polyvinyl alcohols, for polyvinyl alcohols of other structures in the general structural formula of the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com