Preparation methods of graphene-carbon nanotube composite thin film and electrochemical capacitor

A carbon nanotube composite and carbon nanotube technology, which is applied in the manufacture of hybrid/electric double layer capacitors, chemical instruments and methods, graphene, etc., can solve the problem of graphene's low energy storage performance, inability to use energy storage, and graphene Avoid problems such as easy agglomeration of sheets to achieve the effects of preventing agglomeration, high energy storage capacity, and high energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

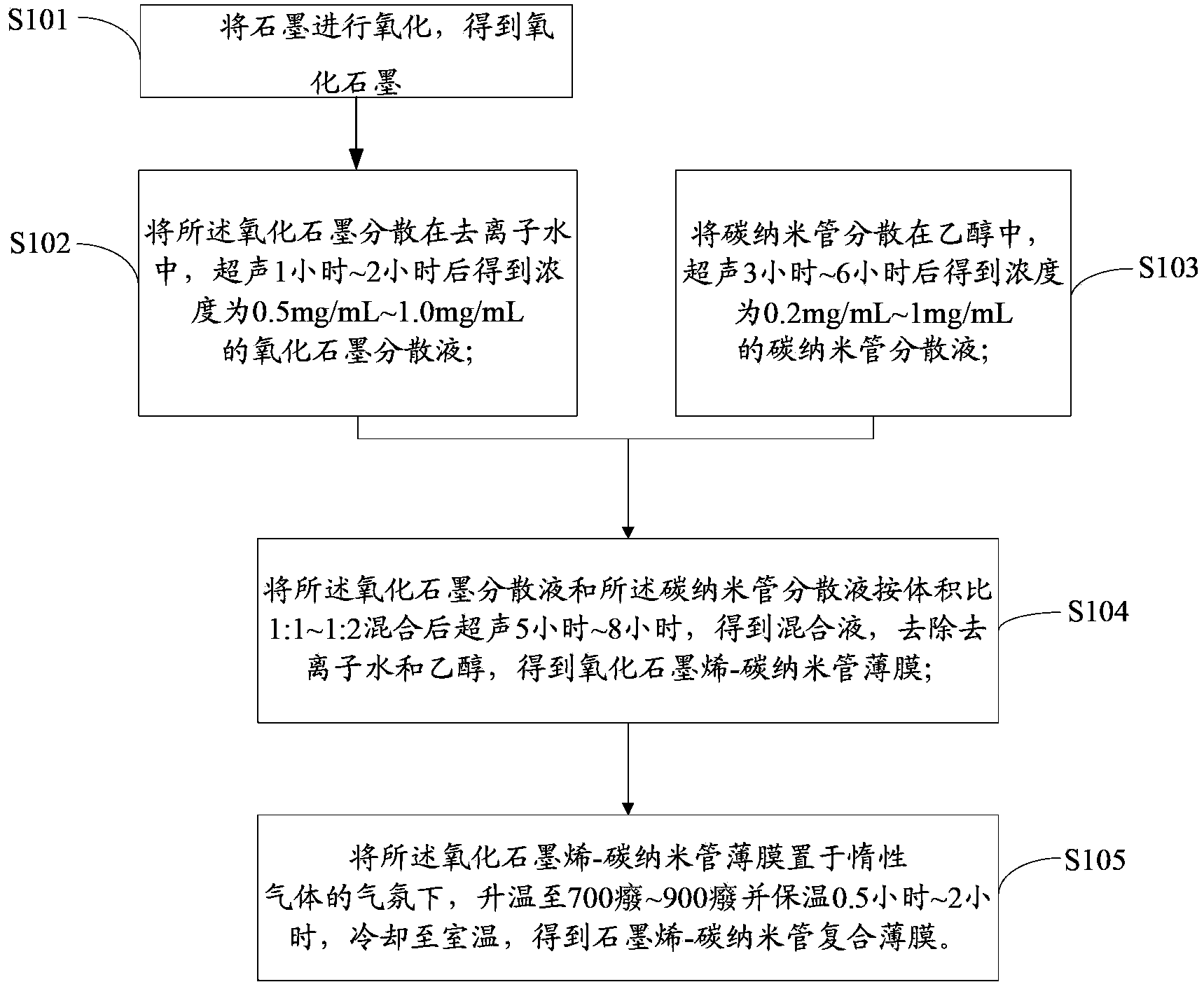

[0034] see figure 1 , the preparation method of the graphene-carbon nanotube composite film of an embodiment comprises the following steps:

[0035] S101, oxidize the graphite to obtain graphite oxide.

[0036] The specific steps are: add graphite to the mixed solution of concentrated sulfuric acid and concentrated nitric acid, stir in an ice-water mixing bath while keeping the temperature at about 0°C; then slowly add potassium permanganate to the mixed solution In the process, because potassium permanganate has strong oxidizing properties under acidic conditions, graphite can be oxidized; then the mixed solution is heated to 85°C for reaction and kept for 30 minutes. During the heat preservation process, graphite can be further oxidized ; Add deionized water, continue to maintain 85 ° C temperature for 30 minutes; then add hydrogen peroxide to the mixed solution, remove excessive potassium permanganate, obtain graphite oxide solution; graphite oxide solution is suction filt...

Embodiment 1

[0057] (1) Weigh 1 g of graphite with a purity of 99.5%, add it to a mixed solution consisting of 90 mL of concentrated sulfuric acid with a mass fraction of 98% and 25 mL of concentrated nitric acid with a mass fraction of 65%, and place the mixture in an ice-water mixing bath environment Stir for 20 minutes; then slowly add 6 g of potassium permanganate to the mixture, stir for 1 hour, heat the mixture to 85° C. and keep it for 30 minutes; add 92 mL of deionized water and continue to keep it at 85° C. for 30 minutes; Add 10mL of hydrogen peroxide solution with a mass fraction of 30%, and stir for 10 minutes; filter the mixture with suction, and then wash the solid matter with 100mL dilute hydrochloric acid and 150mL deionized water successively, washing three times in total, and finally the solid matter C dried in a vacuum oven for 12 hours to obtain graphite oxide.

[0058] (2) Add the graphite oxide prepared in (1) into deionized water, and use an ultrasonic cleaner to son...

Embodiment 2

[0063] (1) Weigh 5 g of graphite with a purity of 99.5%, add it to a mixed solution consisting of 475 mL of concentrated sulfuric acid with a mass fraction of 98% and 120 mL of concentrated nitric acid with a mass fraction of 65%, and place the mixture in an ice-water mixing bath environment Stir for 20 minutes; then slowly add 20 g of potassium permanganate to the mixture, stir for 1 hour, heat the mixture to 85° C. and keep it for 30 minutes; add 92 mL of deionized water and continue to keep it at 85° C. for 30 minutes; Add 30mL of hydrogen peroxide solution with a mass fraction of 30%, and stir for 10 minutes; filter the mixture with suction, and then wash the solid matter with 300mL dilute hydrochloric acid and 450mL deionized water successively, washing three times in total, and finally C dried in a vacuum oven for 12 hours to obtain graphite oxide.

[0064] (2) Add the graphite oxide prepared in (1) into deionized water, and use an ultrasonic cleaning machine with a powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com