Efficient grooving resin wheel for preventing workpiece from being burnt and application thereof

A resin grinding wheel, high-efficiency technology, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems affecting production efficiency, short dressing cycle, large grinding depth, etc., achieve long dressing cycle, high grinding efficiency, reduce Effect of grinding heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

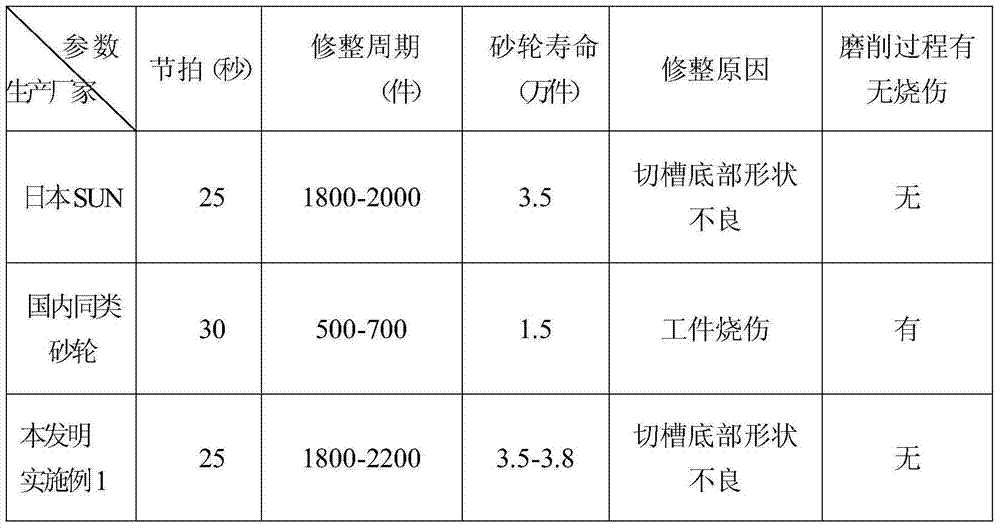

Embodiment 1

[0017] The manufacturing process of grinding wheel adopts general resin bond CBN grinding wheel. The steps of the preparation process are: production preparation, lower abrasive formula, simultaneous rough turning of aluminum substrate with compounding materials, forming of grinding wheel blank, rough turning of grinding wheel substrate, fine turning of grinding wheel substrate, and outer circle dressing of grinding wheel , appearance treatment, final inspection. The mixed filler is calculated by volume ratio: ultrafine WA10 with a particle size of 10-20 μm, and nano-sized SiO with a particle size of 0.03-0.05 μm 2 5. Ultrafine Cu8 with a particle size of 0.5-1.0μm and nano-sized TiO with a particle size of 0.03-0.05μm 2 3, FeS2; polycrystalline diamond 3, CBN20.

Embodiment 2

[0019] The preparation process steps are the same as in Example 1, except that the mixed filler is calculated by volume ratio: ultrafine WA15 with a particle size of 10-20 μm, and nano-sized SiO with a particle size of 0.03-0.05 μm 2 10. Ultrafine Cu10 with a particle size of 0.5-1.0 μm and nano-sized TiO with a particle size of 0.03-0.05 μm 2 5, FeS1; polycrystalline diamond 5, CBN15.

Embodiment 3

[0021] The preparation process steps are the same as in Example 1, except that the mixed filler is calculated by volume ratio: ultrafine WA20 with a particle size of 10-20 μm, and nano-sized SiO with a particle size of 0.03-0.05 μm 2 10. Ultrafine Cu15 with a particle size of 0.5-1.0 μm and nano-sized TiO with a particle size of 0.03-0.05 μm 2 2, FeS3; polycrystalline diamond 8, CBN15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com