A kind of hydrogenation catalyst and its preparation method and the method of light oil hydrofinishing

A hydrogenation catalyst and hydrorefining technology, applied in chemical instruments and methods, catalyst carriers, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of high impurity content, etc. Porosity, effect of reducing olefin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

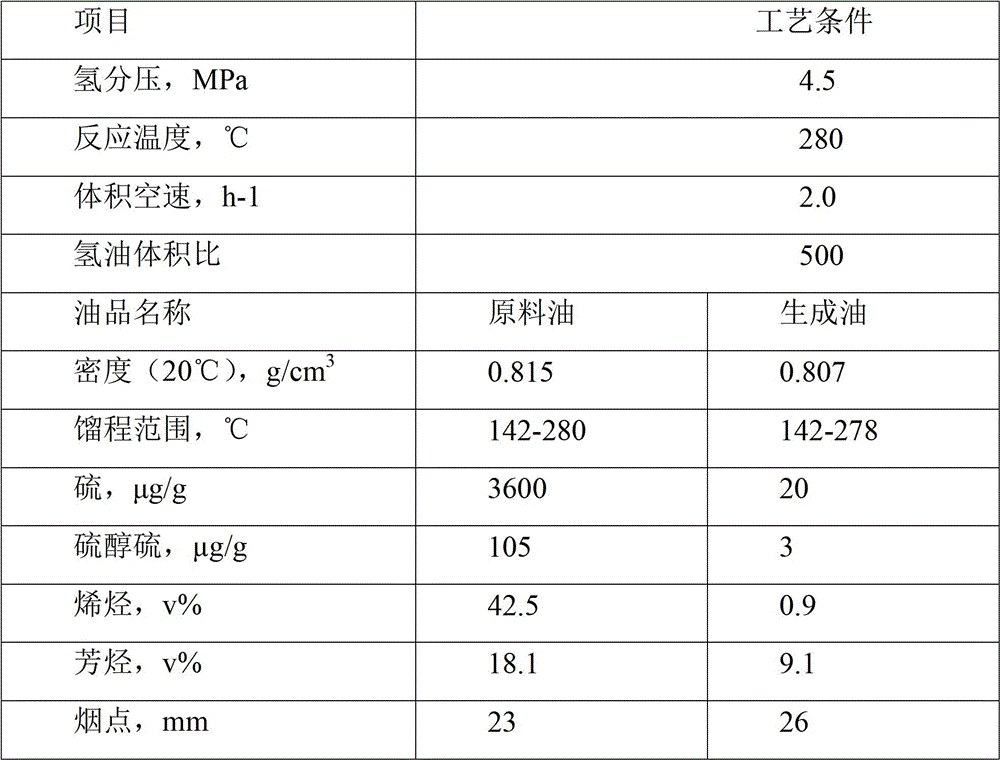

Examples

preparation example Construction

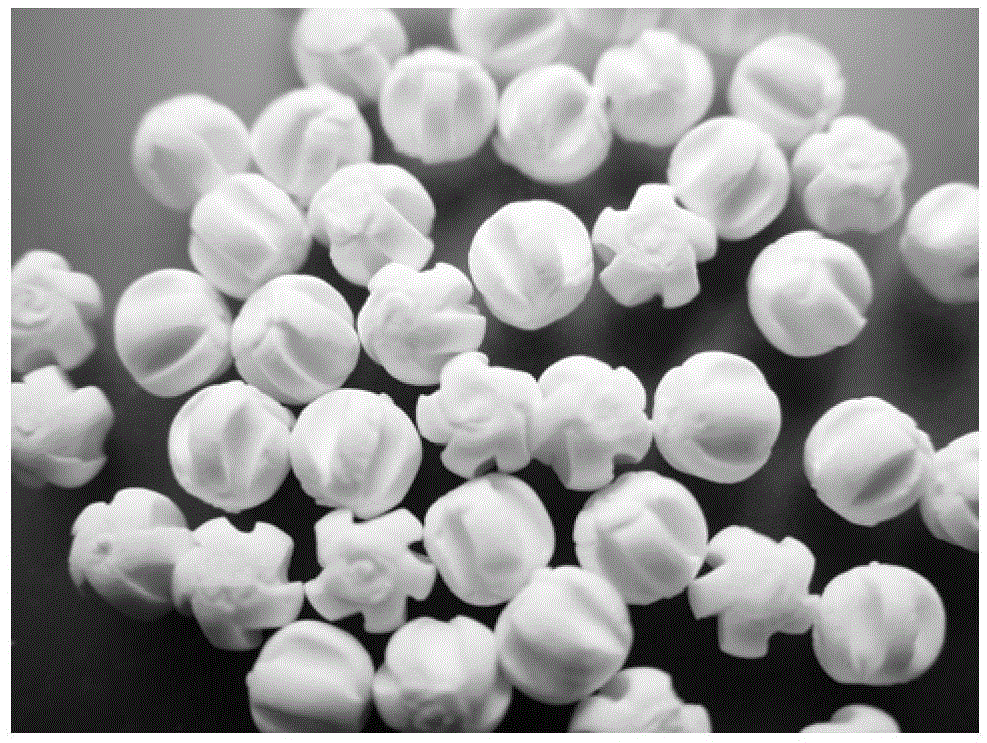

[0028] The present invention also provides a method for preparing a hydrogenation catalyst, which includes the following steps: (1) mixing the aluminum source with a peptizer, a pore-enlarging agent, and a forming aid at a ratio of 1:0.01-0.05:0.01-0.04:0.01- Mix evenly at a weight ratio of 0.06, shape the obtained mixture into a toothed spherical shape, dry and roast to obtain a toothed spherical alumina carrier; (2) mix the soluble salt solution of the VIB group metal component and the VIII group metal component with the step ( 1) The prepared toothed spherical alumina carrier is contacted, and sequentially cured, dried and roasted.

[0029]According to the preparation method provided by the present invention, by mixing the aluminum source with the peptizing agent, the pore expander and the forming aid in the above weight ratio, preferably in a weight ratio of 1:0.01-0.035:0.02-0.03:0.01-0.04, so that The prepared alumina carrier has proper pore volume and specific surface a...

Embodiment 1

[0056] (1) Carrier preparation

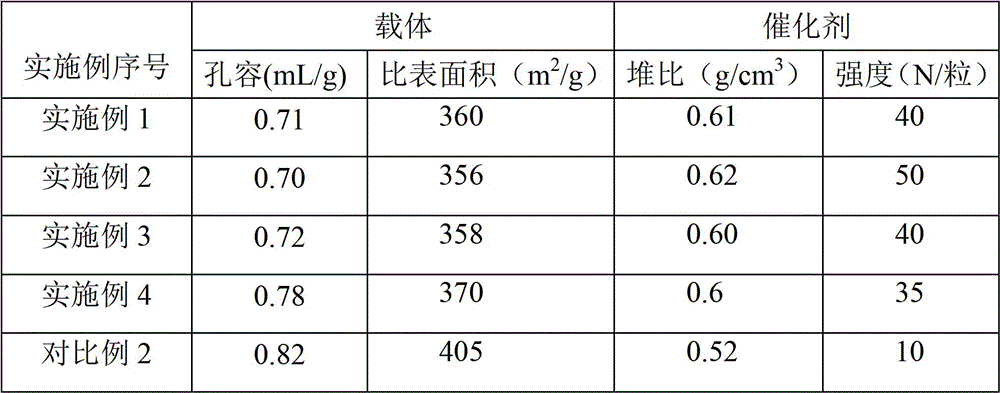

[0057] Mix 100g of aluminum hydroxide dry glue with 22g of 35% by weight phosphoric acid, add 3g of scallop powder, 3g of sodium polyacrylate and mix for 30min, then add 55g of 2% by weight of dilute nitric acid, continue to mix and grind for 40min with a mixer, add In the trough of the extruder, it is extruded through a toothed spherical orifice, and then pelletized by a pelletizing machine to obtain a shaped carrier. Then, it was left standing at 25° C. for 1 hour, dried at 100° C. for 2 hours in an air atmosphere, and then calcined at 500° C. for 4 hours to obtain a toothed spherical alumina carrier with a particle size of 2.5 mm. The appearance of the toothed spherical alumina carrier is as follows figure 1 As shown, each of the toothed spherical alumina carriers has 5 teeth evenly distributed, and the ratio of the maximum width of the groove formed between the teeth to the perimeter of the sphere where the tooth sphere is located is 1:5, ...

Embodiment 2

[0061] (1) Carrier preparation

[0062] Mix 100g of aluminum hydroxide dry glue with 17g of 35% by weight phosphoric acid, add 1g of scallop powder, 3g of sodium polyacrylate and mix for 60min, then add 55g of 6% by weight of dilute nitric acid, continue to mix and grind for 60min with a mixer, add In the trough of the extruder, it is extruded through a toothed spherical orifice, and then pelletized by a pelletizing machine to obtain a shaped carrier. Then, stand at 20°C for 1 hour, dry at 80°C for 4 hours in an air atmosphere, and then bake at 600°C for 3 hours to obtain a toothed spherical oxide with the same shape as in step (1) of Example 1. Aluminum carrier. The pore volume and specific surface area of the toothed spherical alumina carrier are shown in Table 1.

[0063] (2) Catalyst preparation

[0064] Mix 60 g of deionized water, 55 g of ammonium heptamolybdate, and 168 g of nickel nitrate, then add deionized water to prepare a uniform 300 mL solution, and spray th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com