Method for preparing lanthanum-loaded charcoal used for purifying phosphorus polluted water

A biochar and phosphorus pollution technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., to achieve the effects of strong phosphorus removal, reduced environmental risks, and low preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

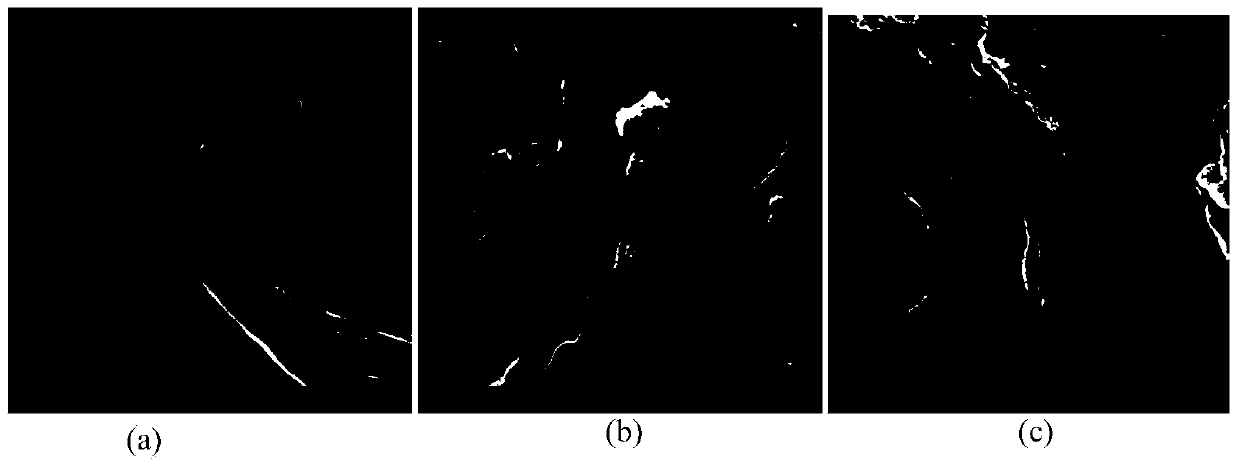

Image

Examples

preparation example Construction

[0024] In the preparation method (process) of the biochar loaded with lanthanum according to the present invention, the ratio of lanthanum element to corn stalk, i.e. w(La) / w (straw), residence time and pyrolysis temperature are all within their respective variation ranges. It may have an important impact on the phosphate removal rate of the final biochar, so the response surface method is used to optimize the preparation process in order to obtain the preparation parameters that can remove phosphate to the greatest extent and reduce the production cost to a certain extent.

[0025] Embodiments 1, 2, and 3 carry out single-factor experiments in the scope involved in the preparation method respectively, so as to determine the variables involved in the response surface method and their scope, so as to improve the fitting degree of the model, and make the optimization result have a higher Credibility and representativeness.

Embodiment 1

[0027]A preparation method of lanthanum-loaded biochar for purifying phosphorus-contaminated water bodies. One of the factors that mainly affects the phosphorus removal effect during the production process is the addition ratio of lanthanum. Phosphate removal effect of the prepared lanthanum-loaded biochar. Its specific implementation is as follows:

[0028] 1) Preparation of biochar raw material A 0 : the same technical scheme as mentioned above;

[0029] 2) Preparation of biochar raw material and lanthanum mixture A 1 : first lanthanum chloride (LaCl 3 ·7H 2 O) add to distilled water, then add A 0 , and its addition ratio is: A 0 The mass volume ratio with distilled water is 1:10 (g / mL), and the mass ratio with lanthanum is 5%, 10%, 15%; while stirring the above mixed solution, add 6M NaOH dropwise until the solution is pH ≥ 10, Continue to stir for 1 hour, then centrifuge at 5000rpm for 5 minutes, pour off the supernatant, wash the remaining solid with ethanol for 3 ...

Embodiment 2

[0033] A preparation method of lanthanum-loaded biochar for purifying phosphorus-contaminated water bodies. One of the factors that mainly affect the adsorption effect during the production process is the roasting temperature of biochar. This example measures the biochar prepared under different roasting temperature conditions. Phosphate removal effect of lanthanum-loaded biochar. Its specific implementation is as follows:

[0034] 1) Preparation of biochar raw material A 0 : the same technical scheme as mentioned above;

[0035] 2) Preparation of biochar raw material and lanthanum mixture A 1 : the same technical scheme as mentioned above;

[0036] 3) Preparation of lanthanum-supported biochar A 2 : put A 1 Crush it and place it in a crucible, then put it into a muffle furnace for 300°C, 400°C, 500°C, 600°C and roast for 60 minutes, cool to room temperature, take it out, and wash the material that has passed through a 60-mesh sieve by centrifugation with distilled water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pyrolysis temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com