Amino acid-containing condensate steam stripping system and tail gas treatment method

A technology containing amino acid and treatment method, which is applied in the field of condensate stripping process, can solve the problems affecting the continuous operation of the whole plant, few control and adjustment measures, and large coupling of the stripping system, so as to avoid corrosion problems and result problems, The effect of reducing the occurrence of corrosive problems and reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

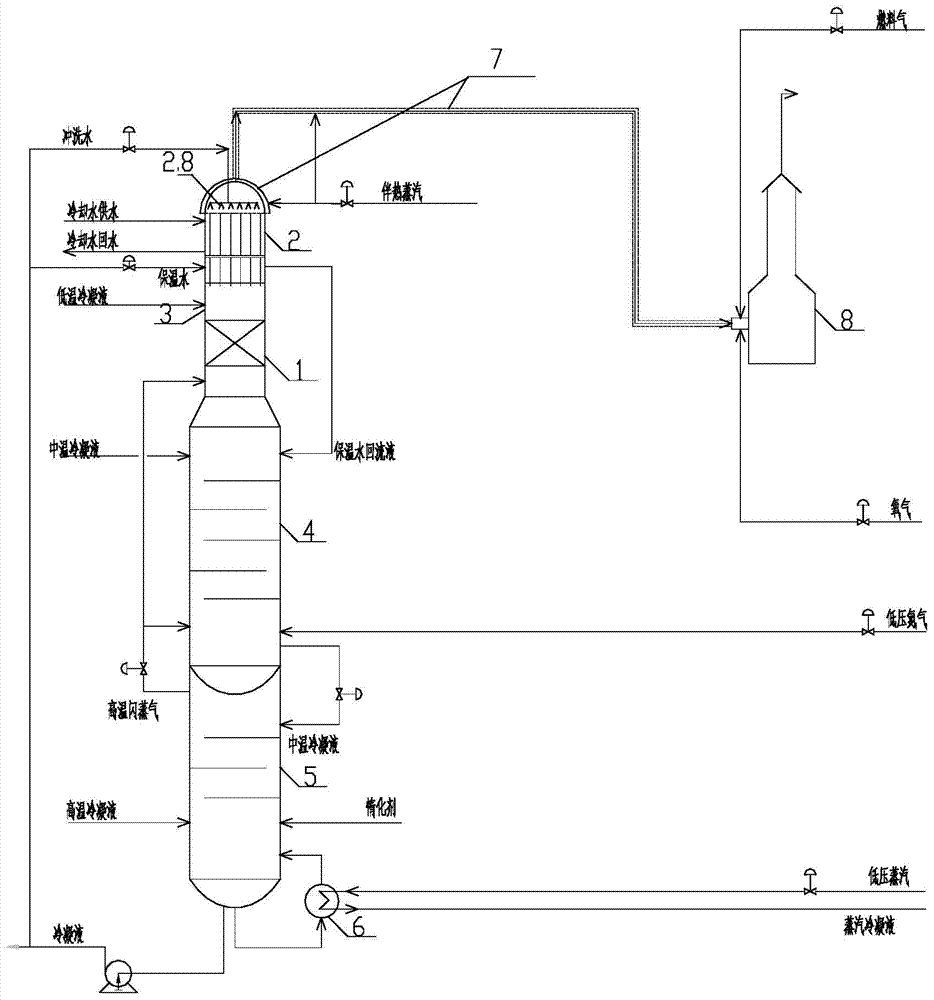

[0032] Below in conjunction with accompanying drawing, process of the present invention is further explained:

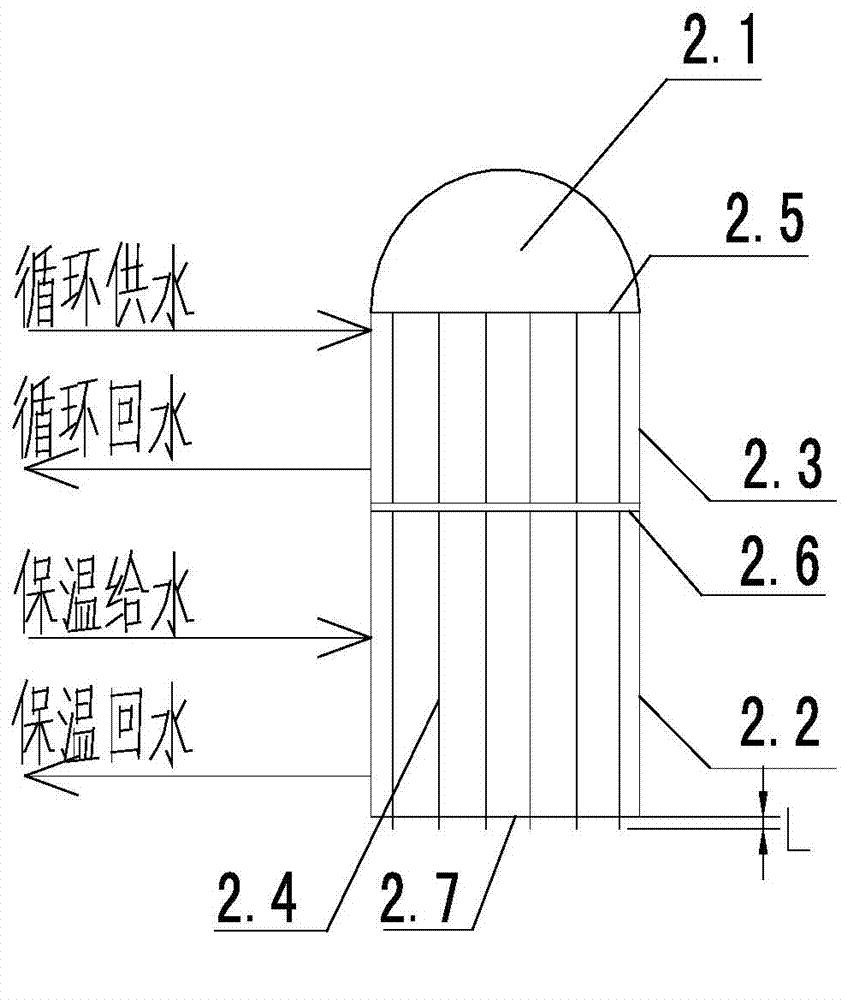

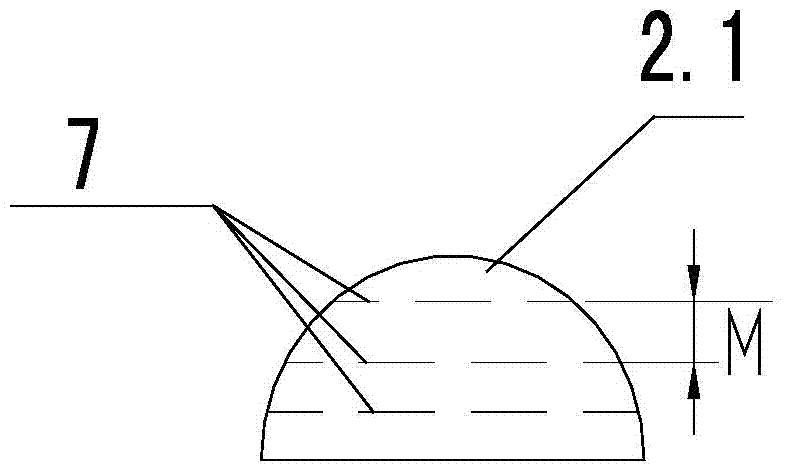

[0033] The stripper 1 of the present invention includes three sections from bottom to top, which are respectively a high-temperature condensate stripping section 5, a medium-temperature condensate stripping section 4, and a low-temperature condensate stripping section 3, and the high-temperature condensate stripping section 5 is equipped with There is a reboiler6. The tower top of described stripper 1 is provided with tower top condenser 2, and described tower top condenser comprises upper tube box 2.1 and the heat exchange section that is connected with upper tube box 2.1, and described heat exchange section is covered by middle tube plate 2.6 Divided into a heat preservation section 2.2 in the lower section and a cooling section 2.3 in the upper section, the upper end of the heat exchange tube 2.4 in the heat exchange section communicates with the upper tube box th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com