Flow mixing method for bauxite forward flotation

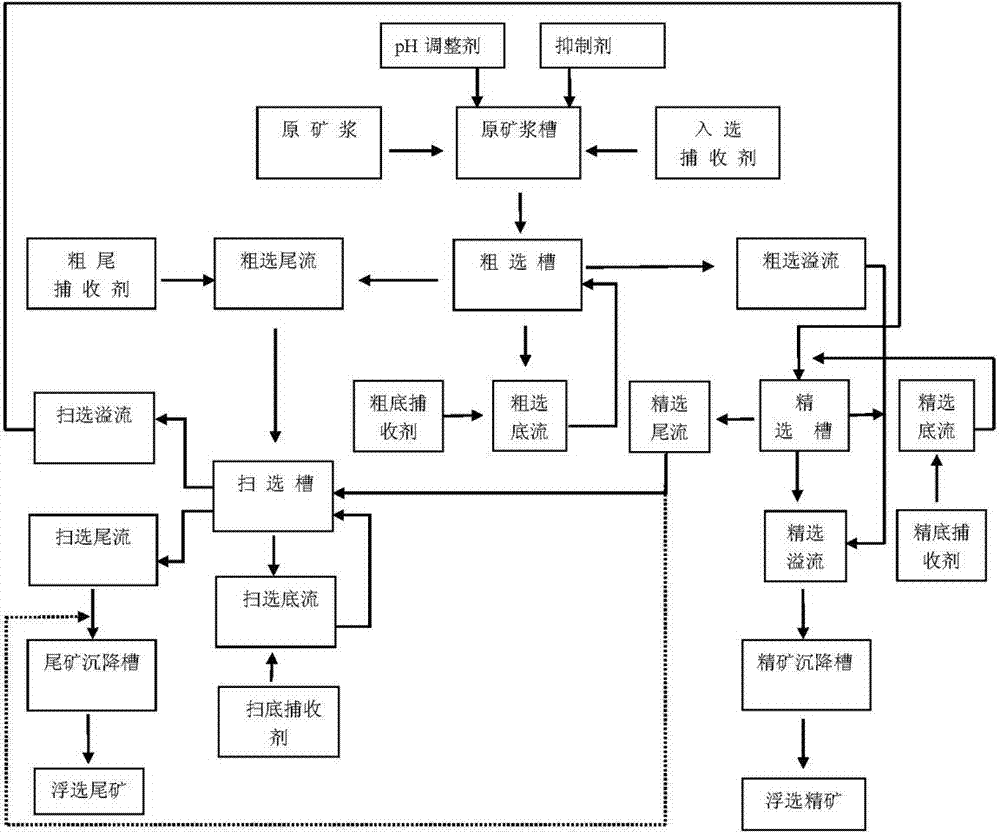

A positive flotation, bauxite technology, applied in flotation, solid separation and other directions, can solve the problems of low yield, long time, large consumption of collectors, etc., to achieve reasonable process configuration, smooth material transfer, The effect of stable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] After passing through the 200-mesh sieve, the raw ore pulp on the sieve is input into the three-step micro-bubble self-circulating flotation machine for flotation, that is, the raw ore pulp enters the raw ore pulp tank, and sodium carbonate is added to adjust the pH value of the raw ore pulp to 8.8, and it is stirred evenly Add sodium hexametaphosphate and selected collector again, add 5g sodium hexametaphosphate and 500g selected collector for every ton of raw ore pulp, stir evenly; The rougher tail flow out of the rougher is mixed with the rougher collector and then enters the sweeping tank. Add 100g of the rougher collector per ton of raw ore pulp, and the rougher underflow from the rougher is mixed with the coarser collector and returns to the rougher Circulate in the selection tank, add 200g of coarse bottom collector per ton of raw ore pulp; the scavenging tail flow from the scavenging tank enters the tailings settlement tank to obtain flotation tailings, after the...

Embodiment 2

[0017] After passing through the 200-mesh sieve, the raw ore pulp on the screen is input into the three-step micro-bubble self-circulating flotation machine for flotation, that is, the raw ore pulp enters the raw ore pulp tank, and sodium carbonate is added to adjust the pH of the raw ore pulp to 8.9, and it is stirred evenly Add sodium hexametaphosphate and the selected collector again, add 47g sodium hexametaphosphate and 300g selected collector for every ton of raw ore pulp, stir evenly, the mixed slurry that comes out from the raw ore pulp tank enters in the rougher tank, and the rougher tank The rougher tail flow out of the rougher is mixed with the rougher collector and then enters the scavenging tank, and 200g of the rougher collector is added per ton of raw ore pulp, and the rougher underflow from the rougher is mixed with the coarser collector and returned to the rougher Circulate in the selection tank, add 100g of coarse bottom collector per ton of raw ore pulp; the s...

Embodiment 3

[0019] After passing through the 200-mesh sieve, the raw ore pulp on the sieve is input into the three-step micro-bubble self-circulating flotation machine for flotation, that is, the raw ore pulp enters the raw ore pulp tank, and sodium carbonate is added to adjust the pH value of the raw ore pulp to 9.0. Stir evenly Add sodium hexametaphosphate and the selected collector again, add 100g sodium hexametaphosphate and 100g selected collector for every ton of raw ore pulp, stir evenly, and the mixed slurry coming out of the raw ore pulp tank enters the rougher tank, and the rougher tank The rougher tail flow out of the rougher is mixed with the rougher collector and then enters the scavenging tank, 300g of the rougher collector is added per ton of raw ore pulp, and the rougher underflow from the rougher is mixed with the coarser collector and returned to the rougher Circulate in the selection tank, add 200g of coarse bottom collector per ton of raw ore pulp; the scavenging tail f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com