Nonaqueous electrolyte secondary cell

A non-aqueous electrolyte, secondary battery technology, used in non-aqueous electrolyte batteries, secondary batteries, battery electrodes, etc., can solve problems such as different safety, fire or rupture properties, to ensure electronic conductivity and suppress discharge capacity. the reducing effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

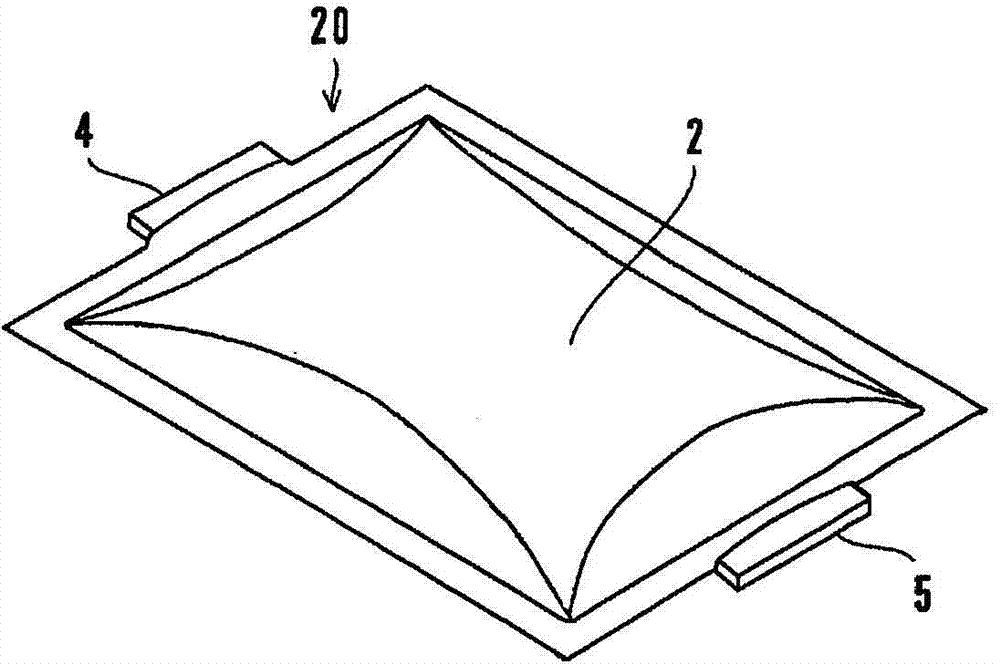

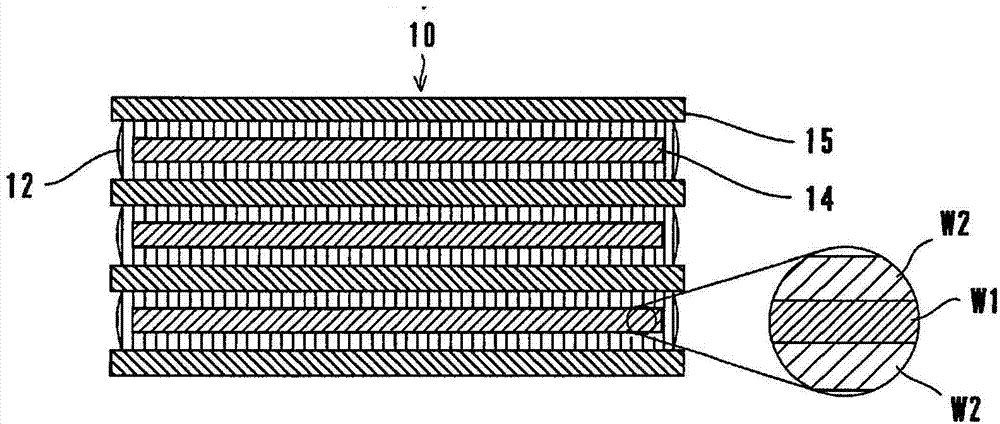

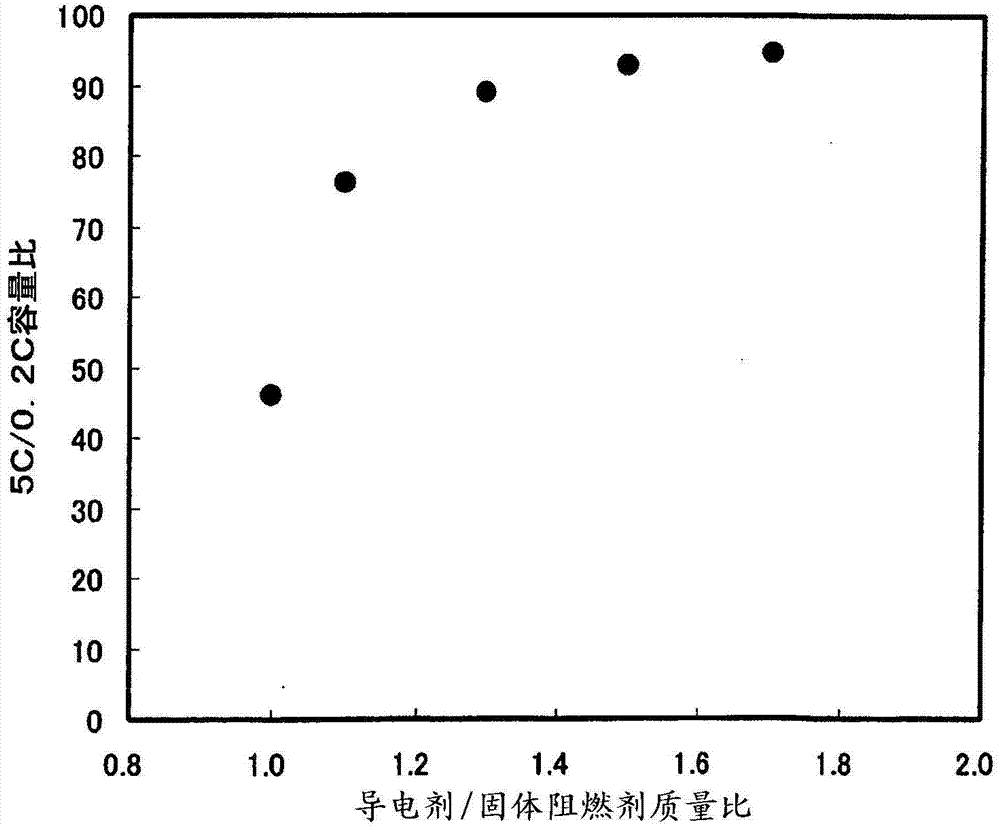

[0042] In Example 1, the amount of the phosphazene compound compounded with the positive electrode mixture was set to be 2.5% by weight relative to the positive electrode active material, and graphite powder (manufactured by Japan Graphite Industry Co., Ltd., trade name JSP, particle size: about 3 μm) and acetylene black (manufactured by Denki Kagaku Kogyo Co., Ltd., trade name HS, particle size: 48 nm) were used as conductive agents. The design capacity of the battery was set to 10 Ah by adjusting the number of laminated electrodes so that the total amount of the positive electrode active material was 130 g (see Table 1). Five types of lithium ion secondary batteries 20 were produced by varying the amount of the conductive agent relative to the amount of the phosphazene compound. The mass ratio of the conductive agent / phosphazene compound was set to 1.0, 1.1, 1.3, 1.5, 1.7.

[0043] Five types of lithium ion secondary batteries 20 were evaluated for high-rate discharge chara...

Embodiment 2)

[0046] In Example 2, the amount of the phosphazene compound compounded in the positive electrode mixture was set to be 5% by weight relative to the positive electrode active material. In the same way as in Example 1, five lithium ion secondary batteries were produced. 20.

[0047] Five types of lithium ion secondary batteries 20 were evaluated in the same manner as in Example 1 for high-rate discharge characteristics. Such as Figure 4 As shown, it was found that as the mass ratio of the conductive agent / solid flame retardant increases, the high-rate discharge characteristics, that is, the capacity ratio of 5C / 0.2C increases. In addition, it has been clarified that by setting the mass ratio of the conductive agent / solid flame retardant in the range of 1.3 to 1.7, high-rate discharge characteristics with a capacity ratio of 80% or more can be obtained. In other words, since the amount of the phosphazene compound was set at 5% by weight relative to the positive electrode activ...

Embodiment 3)

[0049] In Example 3, the amount of the phosphazene compound compounded in the positive electrode mixture was set to be 7.5% by weight relative to the positive electrode active material, and the same operation as in Example 1 was performed except that five kinds of lithium ion batteries were produced. Secondary battery 20.

[0050] About five kinds of lithium ion secondary batteries 20, it carried out similarly to the evaluation of Example 1, and evaluated the high-rate discharge characteristic. Such as Figure 5 As shown, it was found that as the mass ratio of the conductive agent / solid flame retardant increases, the high-rate discharge characteristics, that is, the capacity ratio of 5C / 0.2C increases. In addition, it was clarified that by setting the mass ratio of the conductive agent / solid flame retardant in the range of 1.3 to 1.7, high-rate discharge characteristics with a capacity ratio of basically 80% or more can be obtained. In other words, since the amount of the ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com