Method for processing copper surface of interconnected wire

A copper surface, copper interconnect technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as reducing the reliability of semiconductor devices, and achieve the effect of preventing the diffusion of copper atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

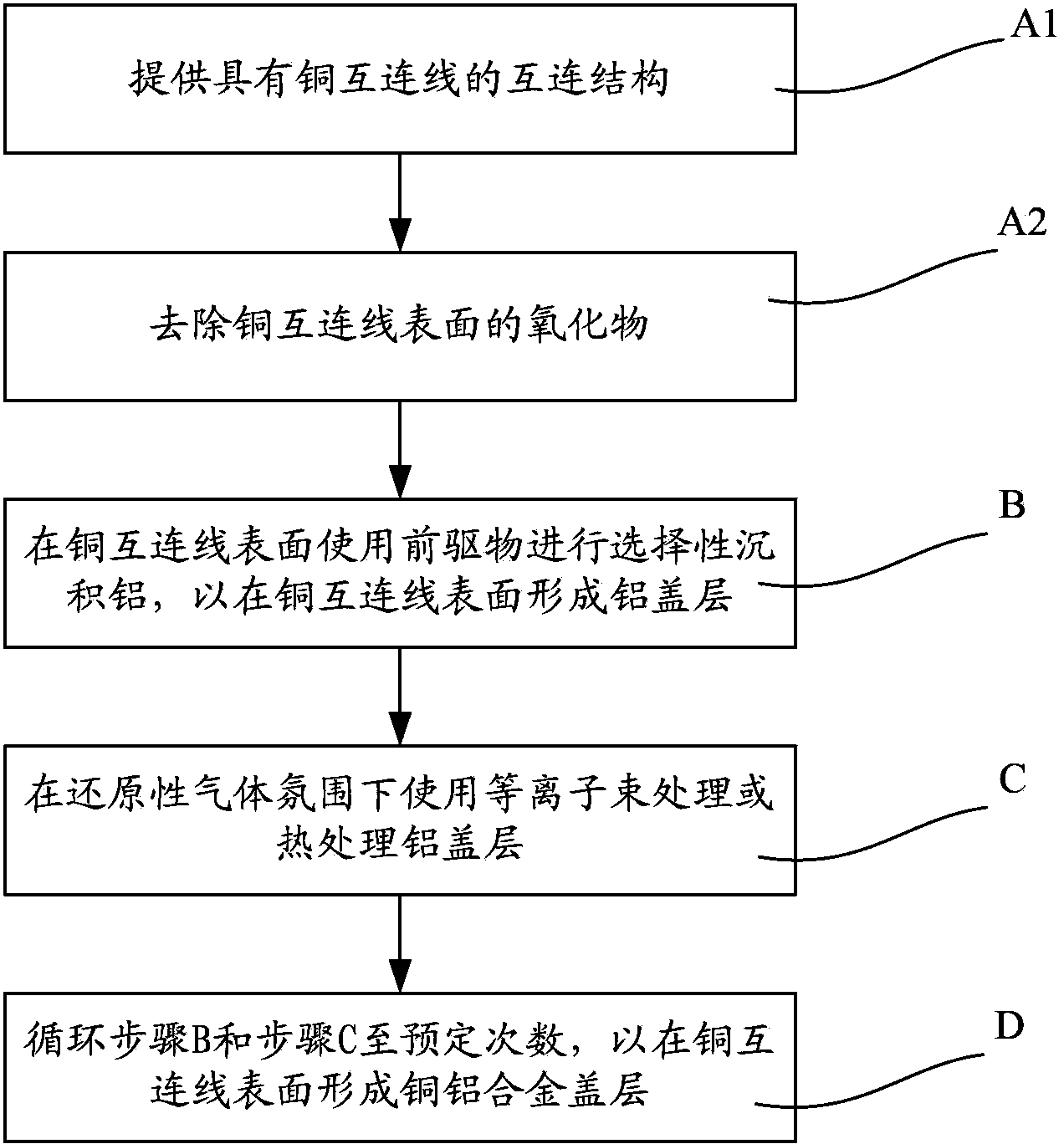

[0022] As a typical embodiment of the copper surface treatment method in a kind of interconnection of the present invention, such as figure 1 shown, including:

[0023] Step A1: providing an interconnection structure with copper interconnection lines;

[0024] Step A2: use plasma beam treatment or heat treatment on the surface of the copper interconnection in a reducing gas atmosphere to remove oxides, preferably, use a plasma beam treatment or heat treatment on the surface of the copper interconnection in a reducing gas atmosphere to remove Oxide, wherein, including using one or any combination of hydrogen, ammonia, helium, or argon, the gas flow rate is 10sccm to 1000sccm, and the temperature is 50 degrees Celsiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com