Full-automatic continuous adjustable extractor hood adopting capacitance-type sensor

A technology of capacitive sensor and range hood, which is applied in the direction of removing oil fume, application, household stove, etc., can solve the problems of normal use, inapplicability, functional failure, etc., so as to avoid the sucking of oil fume, and ensure the service life and work. Stable and smooth smoke exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

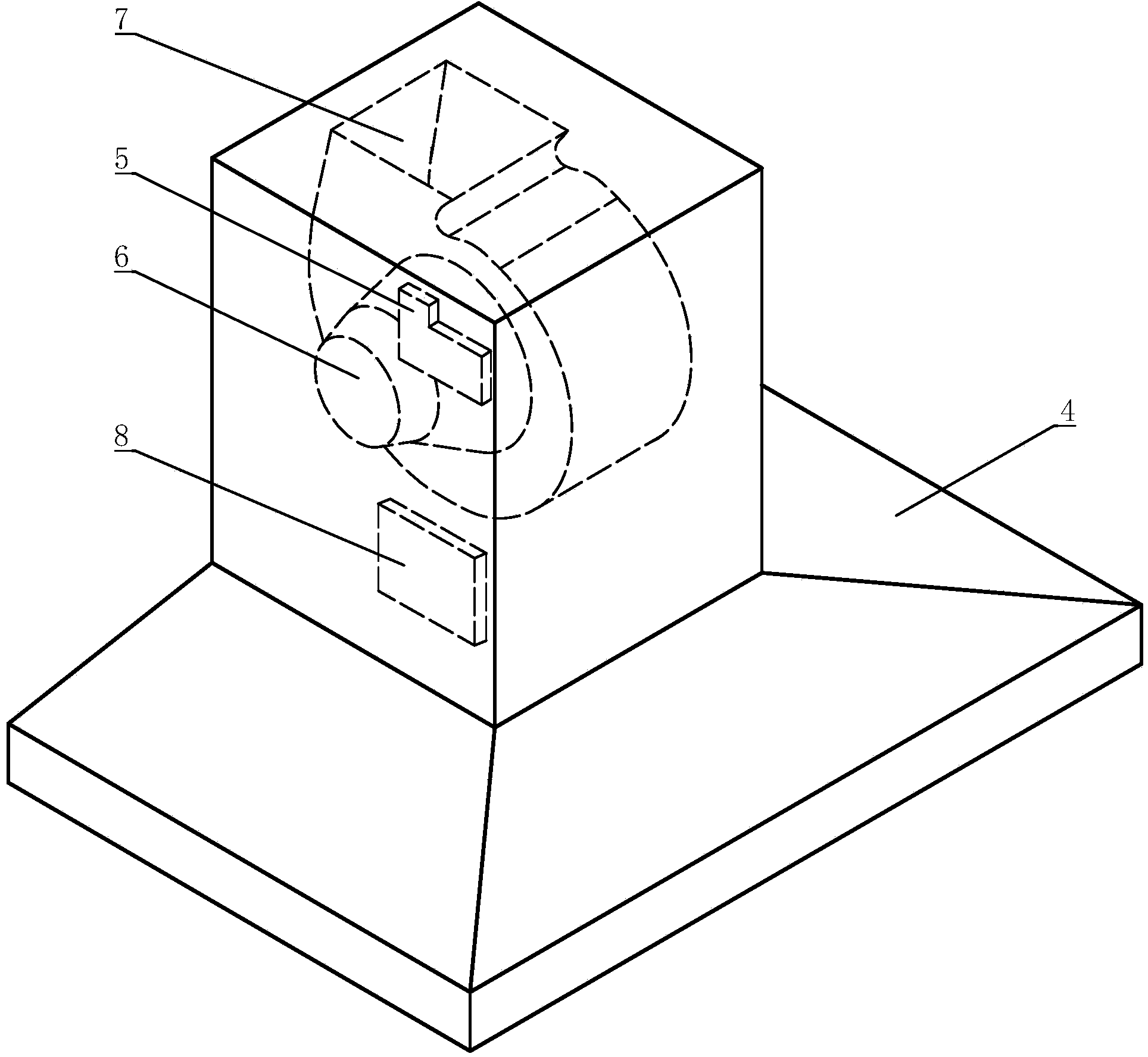

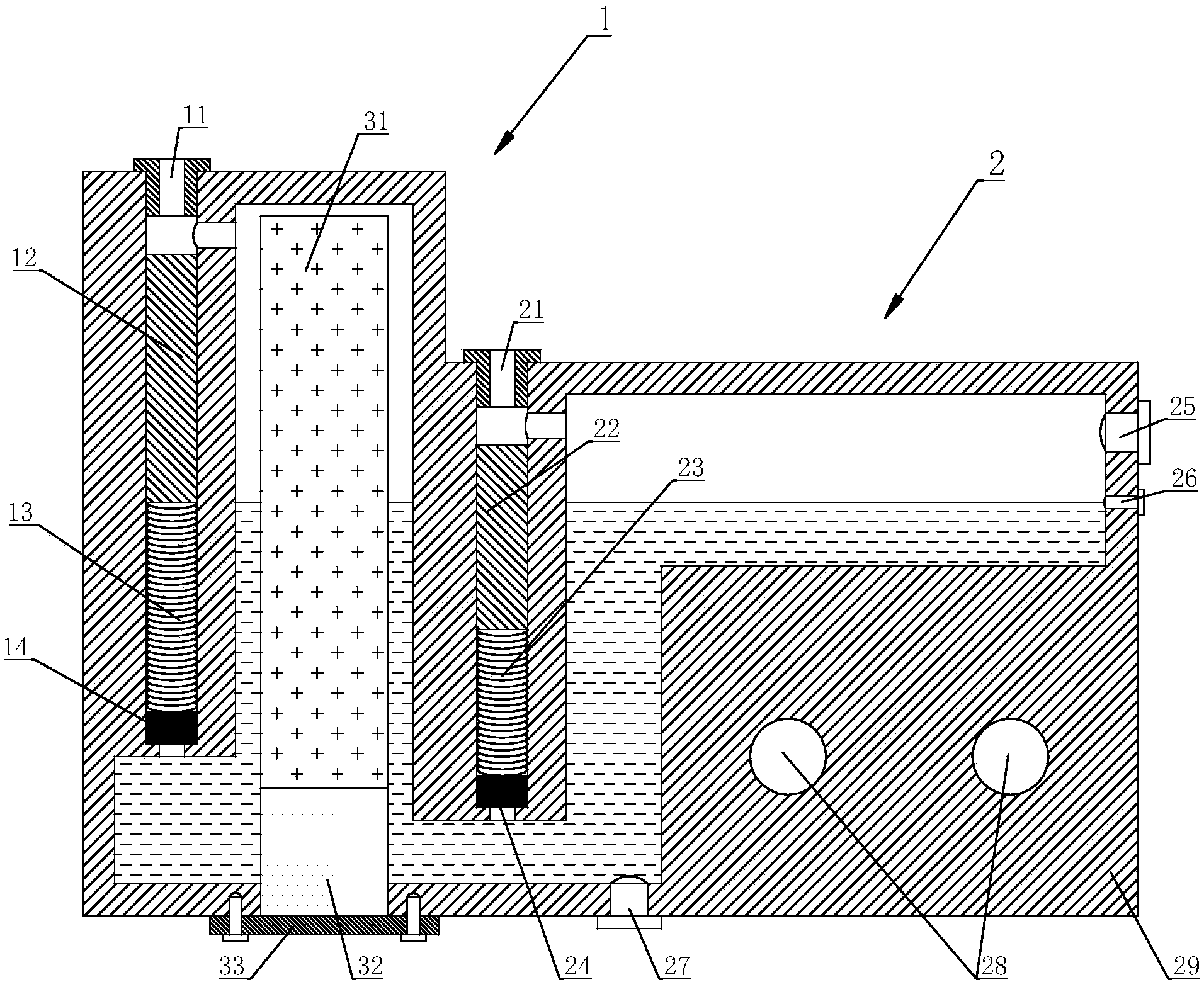

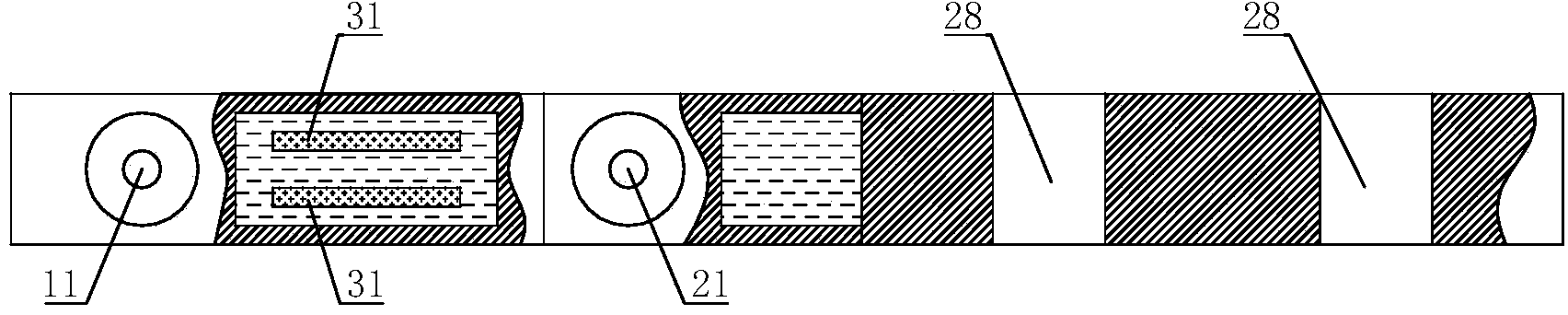

[0031] The present invention adopts the fully automatic continuous adjustable range hood of capacitive sensor, such as figure 1 As shown, it includes a range hood housing 4, a capacitive sensor 5 arranged in the range hood housing 4, a fan 7 driven by a motor 6 and a speed control circuit 8 for controlling the motor 6; as figure 2 As shown, the capacitive sensor 5 includes a body seat with a first chamber 1 and a second chamber 2 inside, and a sensor housing that cooperates with the body seat; the first chamber 1 and the second chamber 2 The bottom is connected, and the inside is filled with a liquid insulating medium; in this preferred example, the liquid insulating medium is transformer oil, which has a relative density of 0.895 and low viscosity, which can meet the use requirements. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com