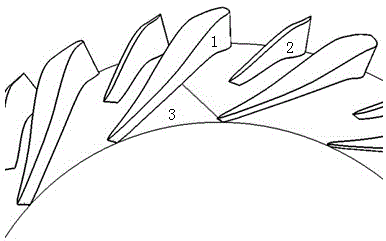

Swept torsion three-dimensional vane diffuser and its design method

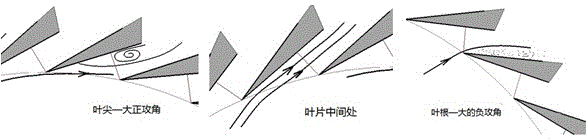

A technology of three-dimensional blades and diffusers, which is applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., and can solve the problem of reducing the working range of the diffuser, decreasing the diffusion capacity of the diffuser, and increasing the degree of shrinkage, etc. problems, to achieve the effect of eliminating airflow separation and load loss on the blade surface, improving flow and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

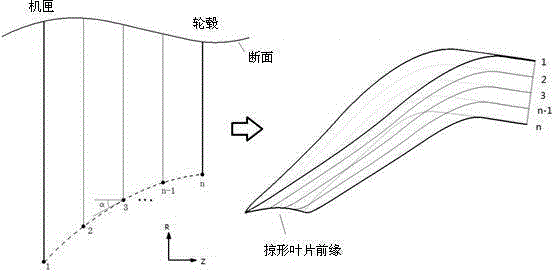

[0054] 1) Determine the overall size of the diffuser, including the inlet diameter of 300mm, the inlet blade height of 15mm, the maximum diameter of 450mm and the axial length of 95mm, and design the shape of the meridian flow channel. Divide the meridian channel of the diffuser into seven sections along the span direction (blade height direction).

[0055] 2) Given that the sweep angle is a constant value of 15° along the span direction, that is, forward sweep, the inlet diameter of the third section (middle section) is the design value of 300mm, combined with the inlet blade height of 15mm, the inlet leading edge curve can be determined (such as attached image 3 Middle left panel, where the grazing angle α =15°, section n=7), and then determine the inlet diameter of section 1~7 d 1 ~ d 7 .

[0056] 3) Determine the channel angles at the inlets of the seven sections according to the distribution law of the incoming airflow angle along the span direction β 1 ~ β 7 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com