Roll cutting continuous excavator

An excavator and rolling cutting technology, applied in the field of rolling cutting continuous mining machines, can solve the problems of large impact of hydraulic system, short service life, low integration, etc., and achieve large cutting face and long service life. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

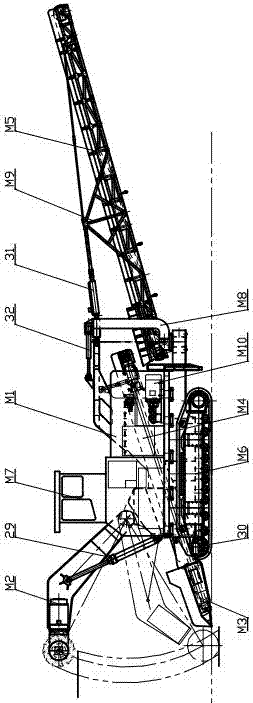

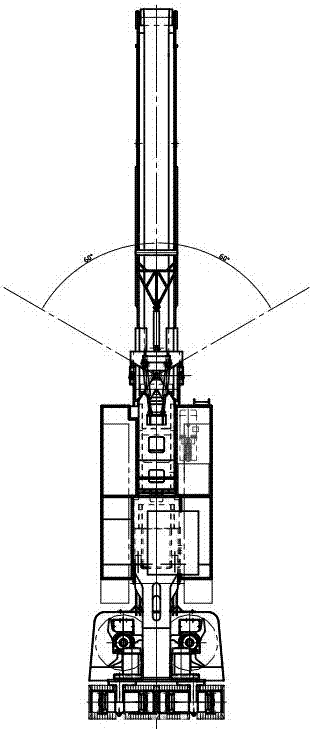

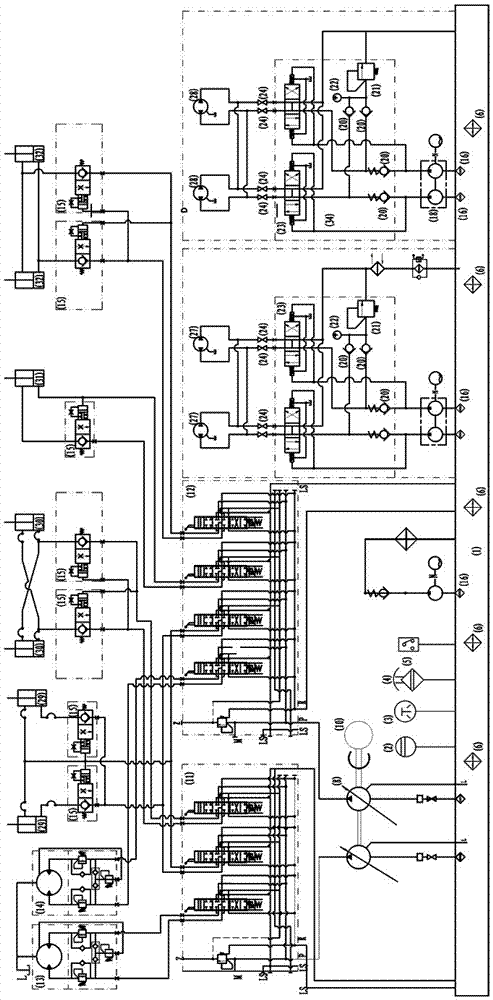

[0063] Such as Figure 1-2 As shown, the roll-cutting continuous excavator mainly includes a frame body M1, a cutting mechanism M2, a star wheel loading mechanism M3, a scraper conveyor M4, a belt conveyor M5 and a hydraulic control system M10. The frame body M1 has a walking track assembly M6 and a cab M7, the walking track assembly includes a left traveling motor 13 and a right traveling motor 14; the cutting mechanism is hinged on the front side of the frame body, and the cutting mechanism Between the middle part of the working arm 101 and the lower part of the front side of the frame body, a working arm lifting cylinder 29 is arranged; The driving roller of the scraper conveyor is driven by the scraper hydraulic motor 27; the star wheel loading mechanism is installed at the front end of the scraper conveyor, and a shovel is arranged between the star wheel loading mechanism and the frame body M1 The lifting cylinder 30, the star wheel of the star wheel loading mechanism is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com