Telescoping venturi siphoning blowdown pipe and design method

A design method and technology for siphon pipes, which are applied in chemical instruments and methods, drainage structures, water/sewage treatment, etc., and can solve problems such as difficult transformation, large pipe diameter, and inability to discharge foam in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

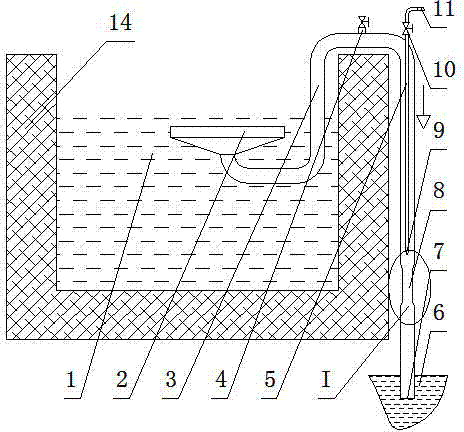

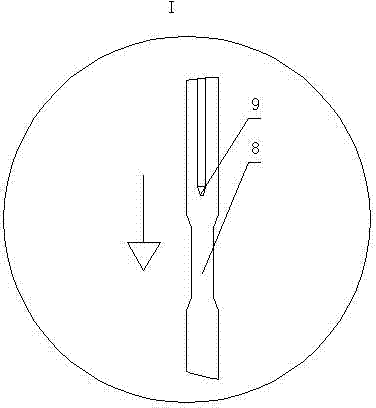

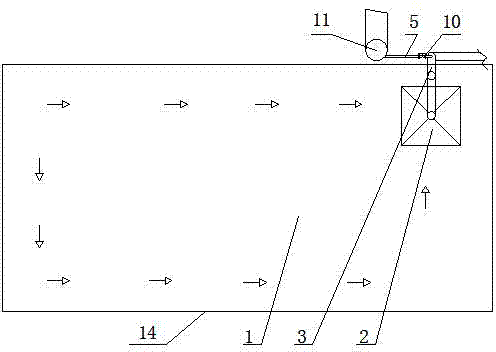

[0113] refer to Figure 1 to Figure 5, the sleeve type Venturi siphon blowdown pipe of the present invention and design method, it comprises siphon pipe 3, air communication valve 4, injection pipe 5 and replenishing water valve 10, and described siphon pipe 3 is serpentine pipe, and the water inlet end of siphon pipe 3 is immersed The bell mouth 2 below the water level 1 of the sump and the outlet 7 are immersed below the water level 7 of the sewage well, and the highest point of the siphon 3 is sealed and connected to the air communication valve 4, and the variable diameter section 8 is set above the outlet 7 of the siphon 3; One end of the injection pipe 5 is provided with a variable diameter head 9 fixedly connected as one, and the other end is sealed and connected with the first group of return water branch pipes 11 of the circulating water through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com