Preparation method for efficient low-impedance antibacterial air purification filter membrane

A technology of air purification and membrane filtration, which is applied in the field of preparation of air filtration membranes, can solve problems such as poor antibacterial properties, high filtration resistance, and low filtration efficiency of composite nanofiber membranes, and achieve high air permeability, reduce filtration resistance, and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 100g of PET into 500ml of TFA / DCM (the volume ratio of TFA and DCM is 4:1) mixed solvent, stir at room temperature for 3 hours until completely dissolved, and prepare PET spinning solution, then add 0.2g After stirring and dissolving, the graphene oxide was prepared into a homogeneous solution for use.

[0020] (2) Add 14g of PA6 into 50ml of formic acid solution, stir for 6 hours until PA6 is completely dissolved in formic acid, then add 0.02g of graphene oxide, stir to dissolve, and obtain a uniform solution for use.

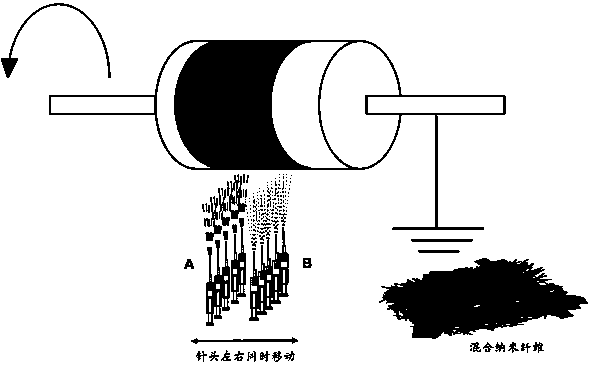

[0021] (3) Put all the above two solutions into the syringe respectively, such as figure 1 As shown, controlling the feed rate of the PET solution to be 10 μl / min and the control voltage to be 20 kV, the feed rate of the PA6 solution to be 4 μl / min and the control voltage to be 18 kV, a PET / PA6 filter membrane is obtained. The average diameter of PET electrospun nanofibers is 700nm, the average diameter of PA6 electrospun nanofibers is only 130...

Embodiment 2

[0024] (1) Dissolve 100g of PAN in 500ml of dimethylformamide (DMF) solvent to prepare PAN spinning solution, stir at room temperature for 4h until completely dissolved, then add 0.5g of graphene oxide, stir to dissolve, A homogeneous solution was obtained.

[0025] (2) Dissolve 12g of PES in 50ml of dimethylformamide (DMF) solvent, stir for 6 hours until PES is completely dissolved in DMF, then add 0.05g of graphene oxide, stir and dissolve to obtain a uniform solution.

[0026] (3) Put all the above two solutions into the syringe respectively, such as figure 1 As shown, the feed rate of PAN solution is controlled to be 15 μl / min and the control voltage is 18 kV, the feed rate of PES solution is 8 μl / min and the control voltage is 22 kV to obtain a PAN / PES filter membrane. The average diameter of PAN electrospun nanofibers is 850 nm, the average diameter of PES electrospun nanofibers is only 200 nm, and the total film thickness is 68 μm.

[0027] After testing, the filter m...

Embodiment 3

[0029] (1) Dissolve 40g PS in 500ml of DMF solvent, stir at room temperature for 4h until completely dissolved, then add 0.5g of graphene oxide, stir and dissolve to obtain a uniform solution.

[0030] (2) Add 10g of PA66 into 50ml of formic acid solution, stir for 6 hours until PA66 is completely dissolved in formic acid, then add 0.05g of graphene oxide, stir and dissolve to obtain a uniform solution.

[0031] (3) Put all the above two solutions into the syringe respectively, such as figure 1 As shown, control the inflow rate of PS solution to be 15 μl / min and the control voltage to be 19kV, the inflow rate of PA66 solution to be 7 μl / min and the control voltage to be 20kV to obtain PS / PA66 filter membrane. The average diameter of PS electrospun nanofibers is 870 nm, the average diameter of PA66 electrospun nanofibers is only 150 nm, and the total film thickness is 30 μm.

[0032] After testing, the filter material has a retention rate of more than 96% for sodium chloride a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com