Novel austenitic stainless steel for ultra (super) critical coal-fired unit

A technology of austenitic stainless steel and thermal power unit, which is applied in the field of heat-resistant austenitic steel to achieve the effect of excellent high temperature tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

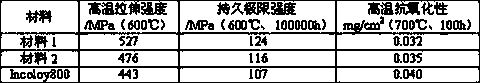

[0020] Material 1 (mass fraction): 0.077%C, 0.47%Si, 0.83%Mn, 0.0029%S, 0.0082%P, 29.73%Ni, 17.84%Cr, 0.39%Nb, 2.03%Mo, 2.73%Al, 0.0086%B , 0.016% N, and the rest is Fe.

[0021] Material 2 (mass fraction): 0.095%C, 0.46%Si, 0.32%Mn, 0.0041%S, 0.009%P, 31.16%Ni, 18.37%Cr, 0.29%Nb, 0.93%Mo, 2.52%Al, 0.0062%B , 0.013% N, and the rest is Fe.

[0022] The material is smelted in a vacuum furnace, and the riser and the bottom of the ingot are removed for forging. The forging process is: heating temperature 1100°C, heating for 2 hours, holding for half an hour, starting forging temperature 1030°C, final forging temperature 960°C, and then proceeding at 1060°C After solution treatment and heat preservation for 1 hour, water cooled to room temperature.

[0023] The austenitic stainless steel involved in the present invention can be cast or rolled as required, and then forged. The process is as follows: heating temperature 1100°C, heating for 2 hours, heat preservation for half an hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com