Smelting furnace for smelting reduction

A reduction furnace and smelting furnace technology, applied in the field of smelting iron and steel, can solve the problems of high production cost, long smelting time, and slow heating speed, and achieve the effects of low production cost, short smelting time, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

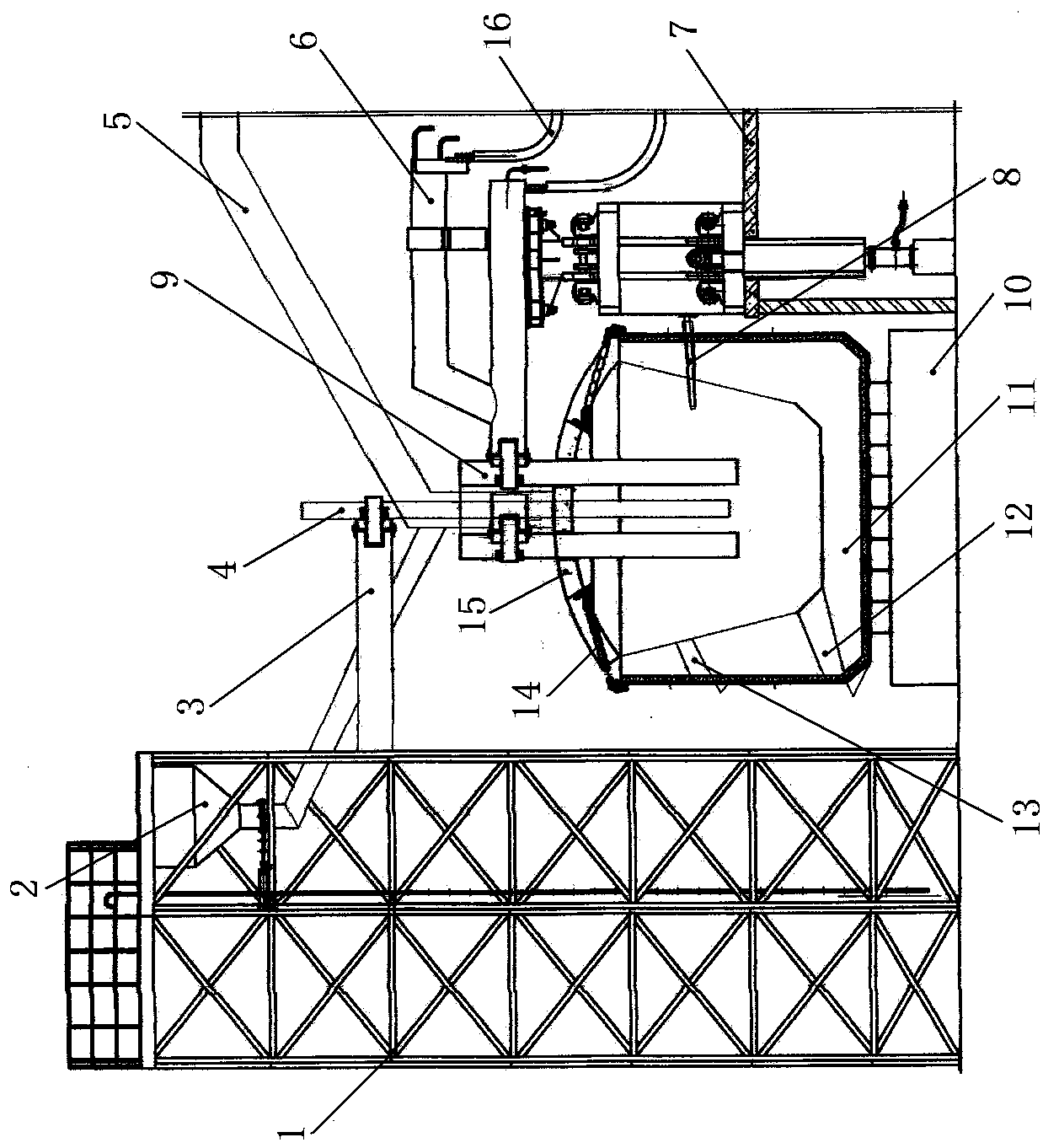

[0007] Referring to the accompanying drawings, it includes a base 10 on which a reduction furnace body 11 made of refractory material is installed, and a furnace cover 15 is connected to the top of the reduction furnace body, and several cooling water pipes 14 are housed in the furnace cover; it is characterized in that: A feed support frame 1 is arranged near the furnace body, and the upper part of the feed pipe 2 is fixed on the feed support frame. There is a feed port on the furnace cover, and the lower end of the feed pipe extends into the feed port on the furnace cover. Several oxygen lance cross arms 3 are also fixed on the support frame, and an oxygen lance 4 is fixed on each oxygen lance cross arm. The oxygen lance extends into the reduction furnace body from the furnace cover or the side wall of the reduction furnace body. It also includes an electrode support frame 7, a plurality of electrode cross arms 6 are fixed on the electrode support frame, each electrode cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com