A kind of square β molecular sieve and preparation method thereof

A beta molecular sieve and square technology, which is applied in the field of in-situ crystallization and synthesis of square beta molecular sieve, can solve the problems of aluminum loss, little activation of silicon oxide, environmental pollution of waste acid liquid, etc., and achieves loose framework, low cost, and reduction of raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Using commercially available montmorillonite as raw material, take the purified montmorillonite, and mix the montmorillonite with NaOH, K 2 CO 3 , TEAOH mixed alkali solution (NaOH, K in the alkali solution 2 CO 3 , TEAOH mass fractions were 15%, 10% and 5%) at room temperature for 1 h, washed, dried, pulverized to 7 μm, and baked in a muffle furnace at 700 °C for 4 h at a heating rate of 5 °C / min. Prepared activated montmorillonite.

Embodiment 2

[0058] Using commercially available montmorillonite as raw material, take the purified montmorillonite, and mix the montmorillonite in a mixed alkali solution composed of NaOH, KOH, and TEAOH (NaOH, KOH, TEAOH in the alkali solution The mass fractions were 10%, 5% and 5% respectively) at 50 °C for 2 h, washed, dried, pulverized to 10 μm, and baked at 850 °C in a muffle furnace at a heating rate of 10 °C / min for 2 h. Get activated montmorillonite.

Embodiment 3

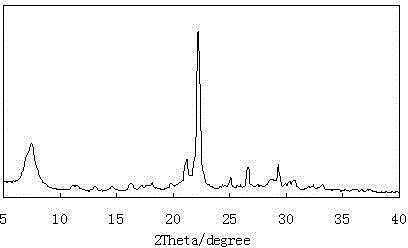

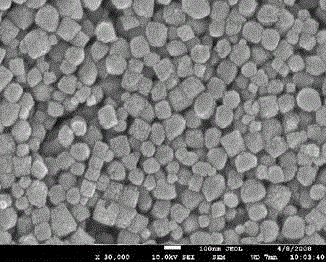

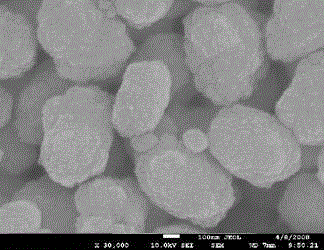

[0060] 30 g of activated montmorillonite in Example 1 was soaked in 60 mL of tetraethylammonium hydroxide with a weight concentration of 25 wt% at 60 °C for 5 h. Then 1.5 g of sodium hydroxide, 0.5 g of sodium chloride, 1.5 g of potassium chloride, 30 mL of distilled water, 40 mL of tetraethylammonium hydroxide with a concentration of 25 wt%, 30 g of white carbon black, and 70 Stirred at ℃ for 4 h to make the mixture gel. The gel was transferred to a stainless steel reactor for static crystallization at 140 °C for 48 h. After the crystallization is completed, cool, filter and separate from the mother liquor, wash and dry the filter cake to obtain a crystallized product. According to X-ray measurement, its phase belongs to β molecular sieve, the relative crystallinity of square β molecular sieve in the product is 80%, and the crystal grain of molecular sieve reaches 80~120 nm. The single-pot yield reached over 70 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com