Weather-resistant solar glass surface anti-reflective film and preparation method thereof

A technology of solar glass and weather resistance, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., to achieve the effect of improving utilization, good bonding force, good mechanical strength and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

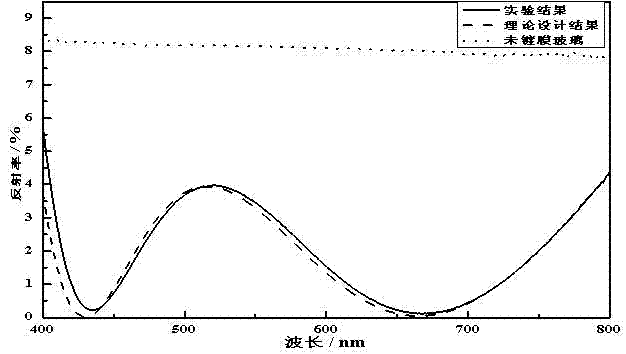

Image

Examples

Embodiment 1

[0026] Butyl titanate (Ti(OC 4 h 9 ) 4 , TBOT), absolute ethanol (EtOH), deionized water (H 2 O), glacial acetic acid (HAc), and acetylacetone (AcAc) in a molar ratio of 1:8:3:1.5:0.2 were fully stirred for 2 hours in an environment with a temperature of about 20 °C and a relative humidity of less than 60%, and then aged for 5 - Obtain transparent titanium oxide sol in 7 days. During the preparation process, first dissolve TBOT in half of EtOH, add HAc dropwise while stirring, and the obtained solution is called A solution; then H 2 O is mixed with the other half of EtOH, and the resulting solution is called B solution; finally, B solution is slowly added dropwise to A solution and stirred evenly.

[0027] Tetraethyl orthosilicate (TEOS), deionized water (H 2 O), hydrochloric acid (HCl) and absolute ethanol (EtOH) according to the molar ratio of 1: 2: 0.2: 40, mixed and stirred evenly, placed in a stable environment (20 ° C, relative humidity 20%) for 7 days to obtain Tr...

Embodiment 2

[0031] Butyl zirconate (Zr(OC 4 h 9 ) 4, TBOZ), absolute ethanol (EtOH), deionized water (H 2 O), glacial acetic acid (HAc), and acetylacetone (AcAc) according to the molar ratio of 1:10:3:2:0.1 were fully stirred at room temperature for 2 hours, and then aged for 5-7 days to obtain a transparent zirconia sol. Pay attention to the order of adding raw materials during the preparation process, AcAc is added to ethanol before TBOZ, and HAc is added before water. Otherwise, the reaction speed is too fast, and the sol will form a suspension or gel.

[0032] The preparation process of silica sol is as described in Example 1.

[0033] Then, in a clean environment with a relative humidity RH lower than 50%, use the pulling method to coat the cleaned ultra-clear glass substrate. During the coating process, a zirconia film was first plated at a speed of V = 12 inch / min, and after the film was dried, it was placed in a muffle furnace for heat treatment at 250°C for 1 hour. After th...

Embodiment 3

[0035] Hafnium tert-butoxide (Hf(OC 4 h 9 ) 4 ), ethanol (EtOH), deionized water (H 2 O), glacial acetic acid (HAc), and acetylacetone (AcAc) according to the molar ratio of 1:8:2.5:2:0.1 were fully stirred at room temperature for 2 hours, and then aged for 5-7 days to obtain a transparent hafnium oxide sol. Pay attention to the order of adding raw materials during the preparation process, AcAc is added to ethanol before hafnium tert-butoxide, and HAc is added before water. Otherwise, the reaction speed is too fast, and the sol will form a suspension or gel.

[0036] The preparation process of silica sol is as described in Example 1.

[0037] Then, in a clean environment with a relative humidity RH lower than 50%, use the pulling method to coat the cleaned ultra-clear glass substrate. During the coating process, the hafnium oxide film was first plated at a speed of V = 11 inch / min. After the film was dried, it was placed in a muffle furnace for heat treatment at 300°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com