Articles having retained strength

A product and flexural strength technology, applied in the field of products with retained strength, can solve the problem of the decrease of the average flexural strength of glass substrates, and achieve the effect of low average flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

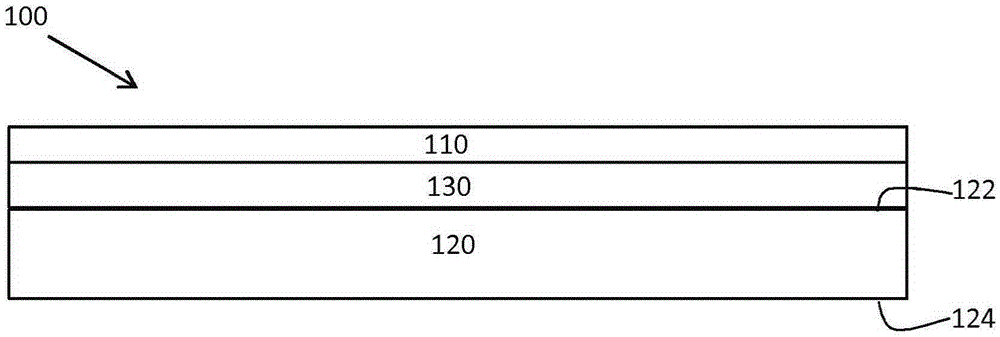

[0144] Examples 1A-1J include articles according to one or more embodiments of the present invention or prior art glass substrates. Examples 1A-1J used commercially available glass substrates of aluminosilicate glass, respectively. The thickness of the glass substrate was 0.7 mm. In Examples 1A-1E, the glass substrate was strengthened by ion exchange to provide a surface compressive stress (CS) of about 690 MPa and a compressive depth of layer (DOL) of about 23 μm. The glass substrate of Example IF was not strengthened by ion exchange. In Examples 1G-1J, the strengthened glass substrate was strengthened by ion exchange to provide a surface compressive stress of about 740 MPa and a depth of compressive layer of about 44 μm. Crack mitigation layers comprising polyimide and / or films comprising indium tin oxide were disposed on strengthened glass substrates and (unstrengthened) glass substrates as provided in Table 1 below. Examples 1A, 1E, 1F, 1G and 1H are shown as comparativ...

Embodiment 2

[0154] Embodiment 2A-2D adopts the glass substrate that comprises following composition respectively: 61mol%≤SiO 2 ≤75mol%; 7mol%≤Al 2 o 3 ≤15mol%; 0mol%≤B 2 o 3 ≤12mol%; 9mol%≤Na 2 O≤21mol%; 0mol%≤K2 O≤4mol%; 0mol%≤MgO≤7mol%; 0mol%≤CaO≤3mol%, and 0mol%≤SnO 2 ≤1 mol%. The glass substrate had a thickness of 0.7 mm, strengthened by ion exchange and bonded crack mitigating layers and / or films were prepared using the same procedure as described above in relation to Examples 1A-1J. The strengthened glass substrates of Examples 2A-2D had a surface compressive stress (CS) of about 776 MPa and a compressive depth of layer (DOL) of about 41.4 μm. A crack mitigation layer comprising polyimide and a film comprising indium tin oxide were disposed on the strengthened glass substrates provided in Table 2 below, using the methods described in relation to Examples 1A-1J to provide examples 2A-2D. products. Adhesion promoters were used in the same manner as in Examples 1B-1D, 1I and 1J...

Embodiment 3

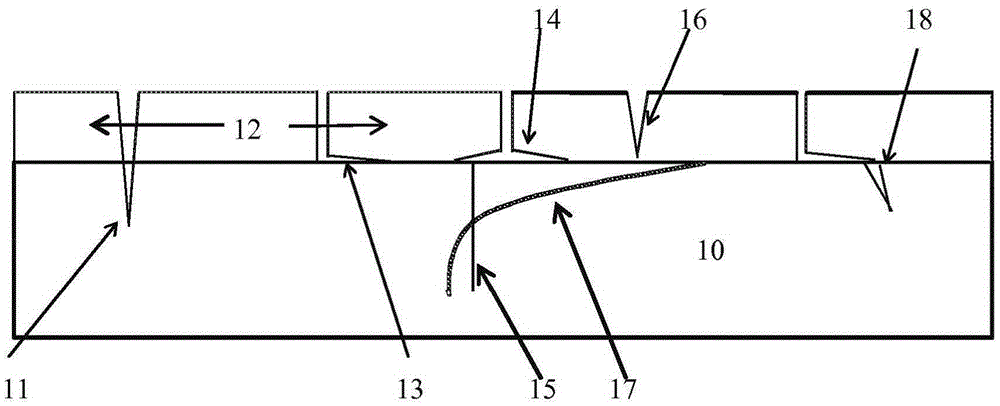

[0160] Embodiments 3A-3C are contemplated embodiments as Figure 7-9 As shown, with Figure 10-12 Correlation model optical reflectance data shown. Examples 3A and 3B are associated with Examples 4C and 4E, respectively, as described below. Examples 3A-3C include articles 300, 310, 320 that include a glass substrate 302, 312, 322, respectively, a crack mitigation layer 304 comprising polyimide disposed on the glass substrate 302, 312, 322, 314, 324, and a film 306, 316, 326 comprising indium tin oxide disposed on said glass substrate 302, 312, 322 such that the crack mitigation layer is between the glass substrate and the film. In Examples 3A-3C, the glass substrates had a thickness of about 0.2-2 mm, respectively. Example 3A included a crack mitigation layer 304 with a thickness of 74 nm and a film 306 with a thickness of 115 nm. Example 3B included a crack mitigation layer 314 with a thickness of 85 nm and a film 316 with a thickness of 23 nm. Example 3C included crack ...

PUM

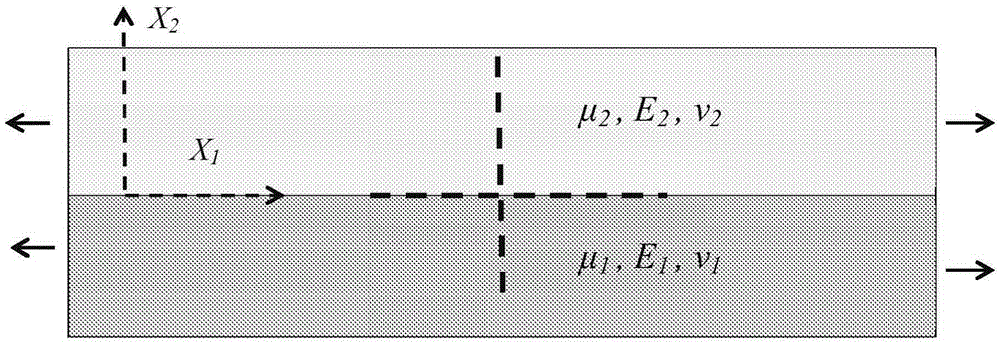

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com