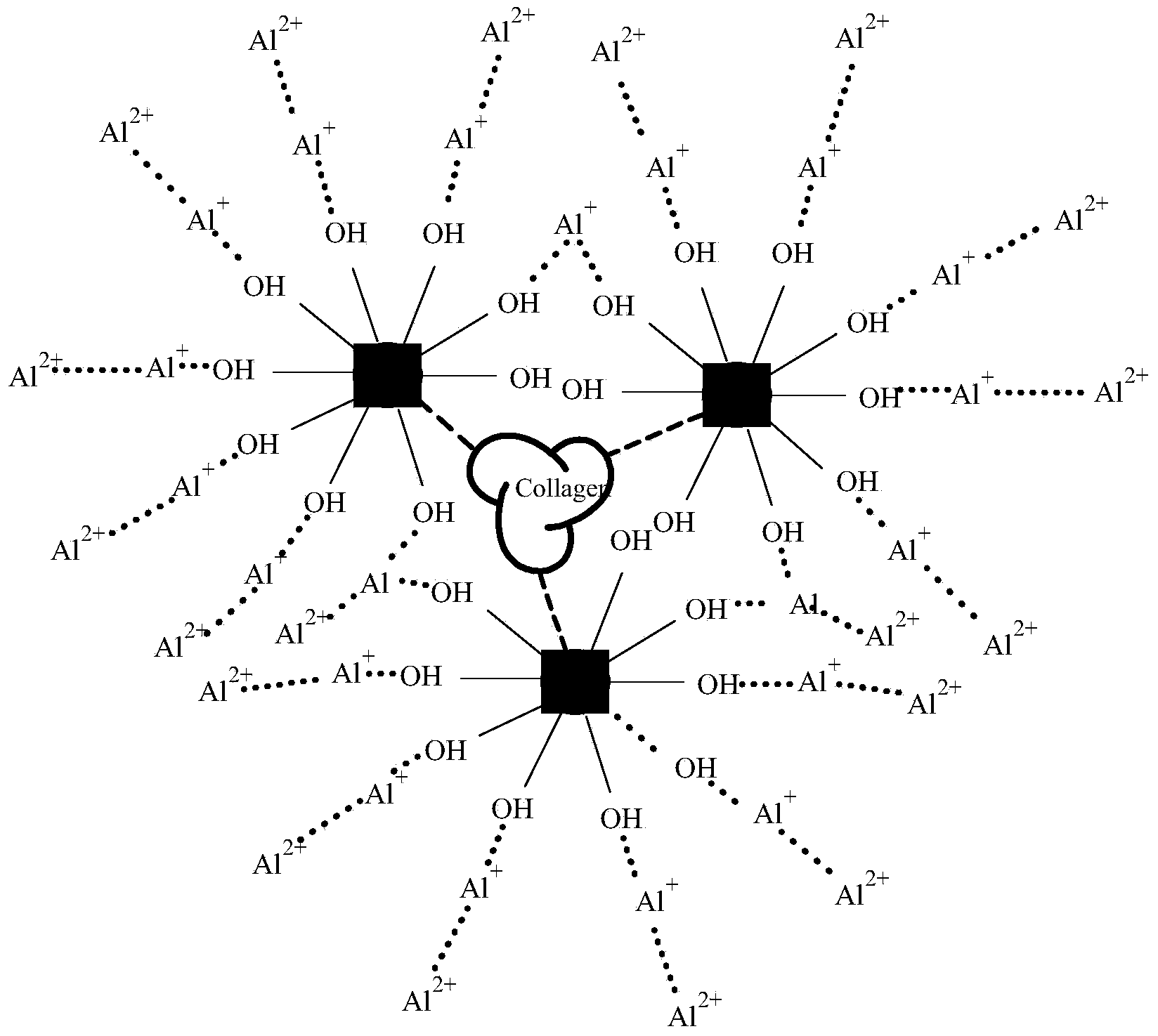

Synthetic method of collagen hyperbranched polyester/metallic ion loaded fluoride adsorbent

A technology of hyperbranched polyester and collagen, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of large amount of adsorbent, secondary pollution, incomplete adsorption, etc., and achieve cost Inexpensive, easy to recycle, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The synthesis method of the collagen-loaded hyperbranched polyester / metal ion fluoride adsorbent of the present invention includes the following steps:

[0024] 1) Synthesis of loaded hyperbranched polyester collagen

[0025] 1.1) Dissolve the hydroxyl-terminated hyperbranched polyester in a hydrophilic organic solvent, and then add a crosslinking agent to it, wherein the molar ratio of the hydroxyl-terminated hyperbranched polyester to the crosslinking agent is (8~32): 1. Adjust the pH to 4.5~10, and then react at 30~50℃ for 1.5~3h; among them, the hydroxyl-terminated hyperbranched polyester is Boltorn H20, Boltorn H30 or Boltorn H40. Boltorn H20 is the only one that has reached the pilot scale in the world. The hyperbranched polyester produced is a second-generation hyperbranched polyester synthesized by the "divergent method" using ethoxylated pentaerythritol and dimethylolpropionic acid as raw materials. Its theoretical molecular terminal hydroxyl number is 16, and its r...

Embodiment 1

[0034] 1) Synthesis of loaded hyperbranched polyester collagen

[0035] 1.1) Dissolve Boltorn H20 in 10 mL of dimethyl sulfoxide (DMSO), add epichlorohydrin, and the molar ratio of hydroxyl to epichlorohydrin on the surface of the hydroxyl-terminated hyperbranched polyester is 8:1, by dropping 1 mol / L NaOH solution to adjust the system pH to 10, react at 30°C for 2h;

[0036] 1.2) After the reaction, rinse with deionized water until no epoxy groups are detected in the cleaning solution;

[0037] 1.3) Wash the collagen with 10%, 30%, 50% DMSO aqueous solution, and vacuum the cleaning solution after each cleaning. According to the molar ratio of the amino groups on the collagen surface to the epichlorohydrin is about 0.8:1, add DMSO to the clean collagen to prepare a collagen suspension, and add Boltorn H20 activated by epichlorohydrin to the collagen suspension In the liquid. The reaction system was heated to 50°C and reacted for 18 hours under sealed conditions. The product obtai...

Embodiment 2

[0041] 1) Synthesis of loaded hyperbranched polyester collagen

[0042] 1.1) Dissolve Boltorn H30 in 10 mL of N,N-dimethylformamide (DMF), add divinyl sulfone, and the molar ratio of the hydroxyl-terminated hyperbranched polyester surface to the crosslinking agent is 16:1. Add 0.5mol / L HCl solution to adjust the pH of the system to 4.5, and react at 40℃ for 2h;

[0043] 1.2) After the reaction, rinse with deionized water until no divinyl sulfoxide is detected in the cleaning solution;

[0044] 1.3) Wash the collagen with 10%, 30%, 50% DMF aqueous solution, and vacuum the cleaning solution after each cleaning. According to the molar ratio of the amino groups on the collagen surface to the divinyl sulfoxide of about 1:1, add DMF to the clean collagen to prepare a collagen suspension, and add Boltorn H30 activated by divinyl sulfoxide to the collagen Protein suspension. The reaction system was heated to 60°C and reacted for 15 hours under sealed conditions. The product obtained was w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com