High temperature resistance tag device

A high-temperature-resistant, labeling technology, applied to record carriers, instruments, computer parts, etc. used in machines, can solve the problems of reducing transportation efficiency and production efficiency, slow and busy information query, and improve transportation efficiency and production efficiency. Improve the degree of automation and the effect of small design volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

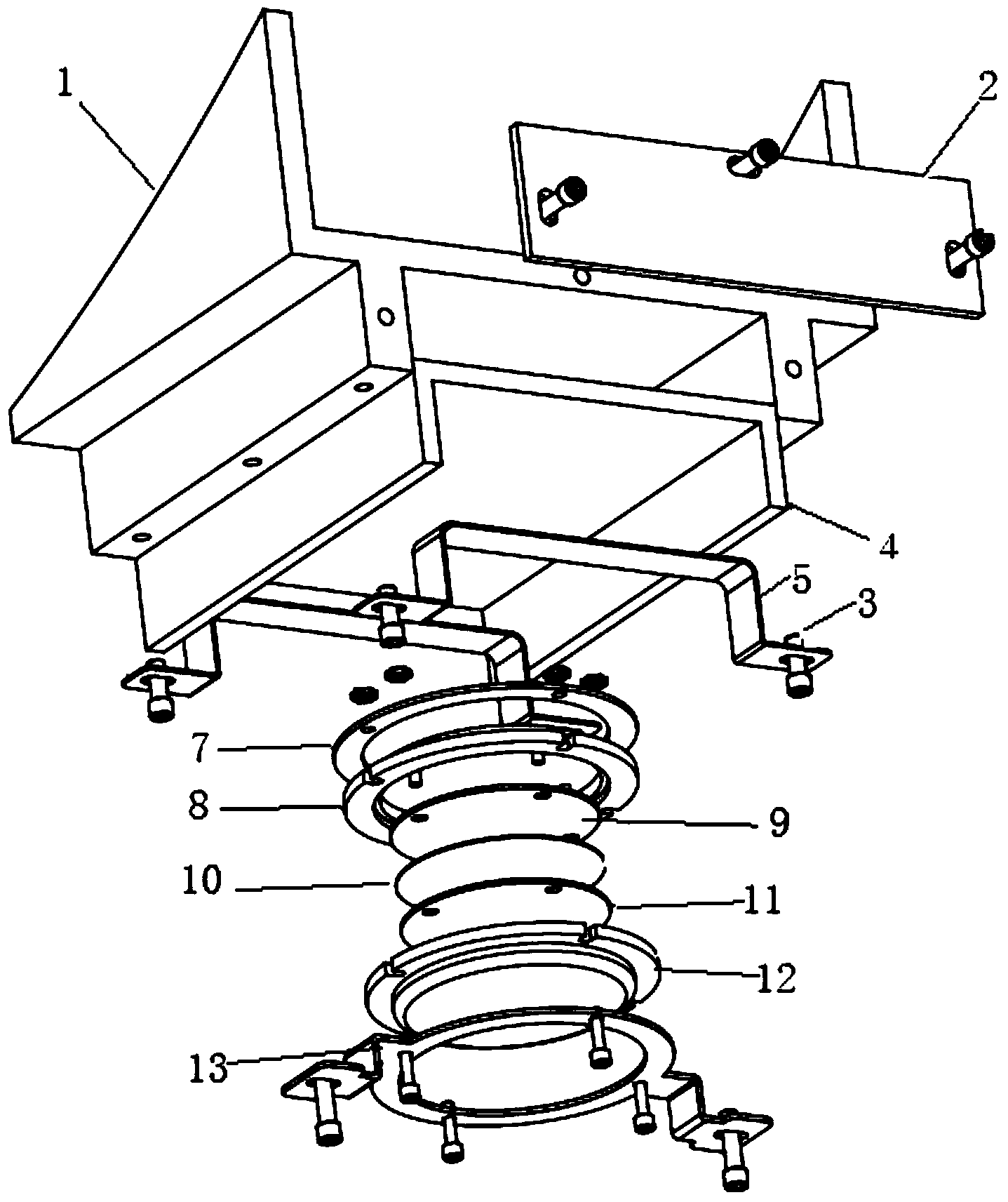

[0024] The high temperature resistant shell includes a silica gel upper cover 8, a first asbestos gasket 9, a second asbestos gasket 11, and a silica gel lower cover 12; the silica gel upper cover and the silica gel lower cover cooperate to form a closed cavity, and the closed cavity A first asbestos gasket and a second asbestos gasket are arranged in the middle, and the RFID tag 10 is placed between the first asbestos gasket and the second asbestos gasket.

[0025] The high temperature resistant shell also includes a first silica gel fixing ring 7 and a second silica gel fixing ring 13; the first silica gel fixing ring is arranged above the silica gel upper cover 8 for fixing the silica gel upper cover on the label base, and the second Two silica gel fixing rings 13 are arranged under the silica gel lower cover and are used to fix the high temperature resistant shell on the label base.

[0026] An airgel pad 4 is also included, and the airgel pad is arranged between the first...

Embodiment 2

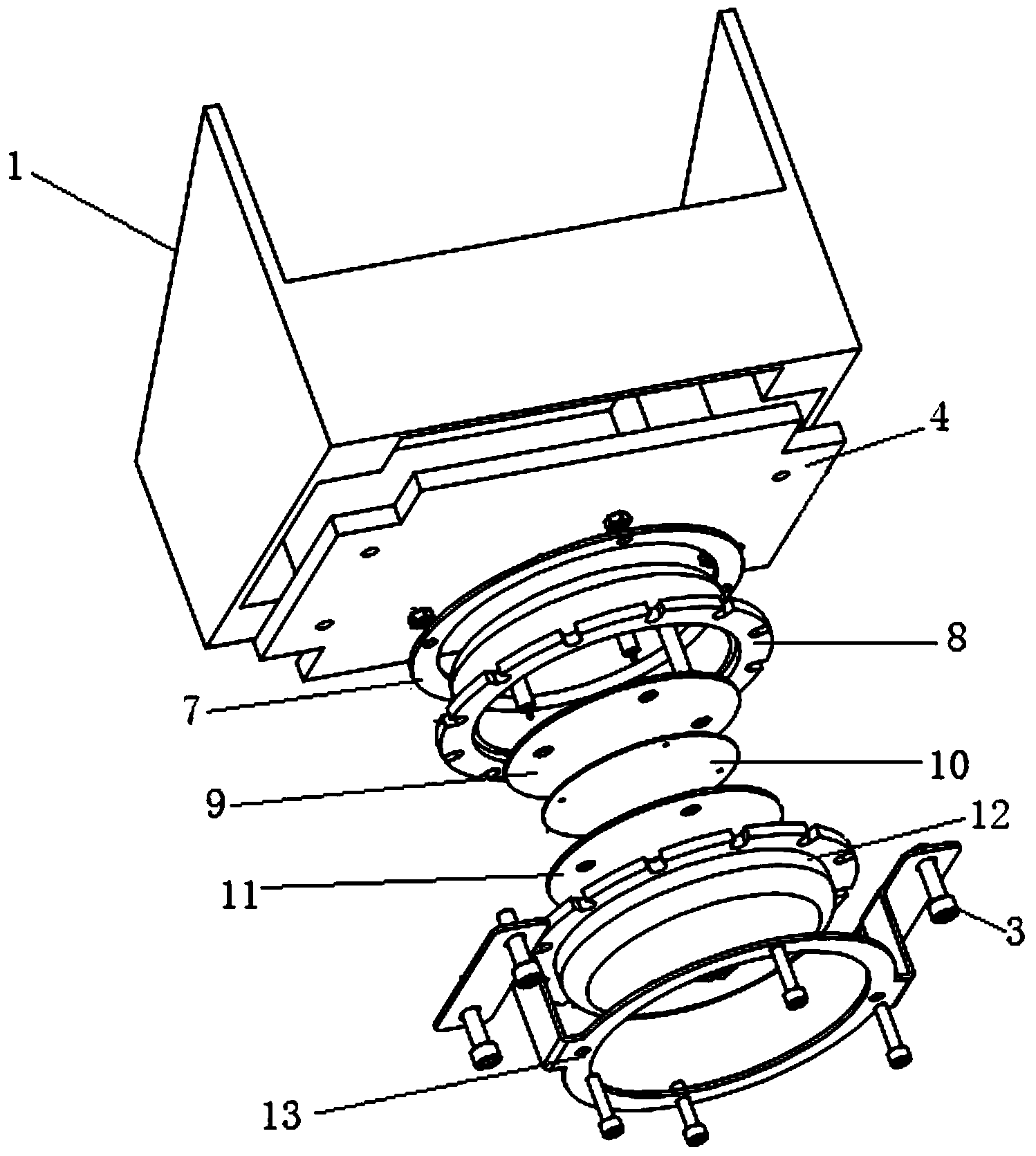

[0034] The high temperature resistant shell includes a silica gel upper cover 8, a first asbestos gasket 9, a second asbestos gasket 11, and a silica gel lower cover 12; the silica gel upper cover and the silica gel lower cover cooperate to form a closed cavity, and the closed cavity A first asbestos gasket and a second asbestos gasket are arranged in the middle, and the RFID tag 10 is placed between the first asbestos gasket and the second asbestos gasket. The silica gel upper cover and the silica gel lower cover are used to protect and fix the label, and have a certain effect of heat resistance and heat insulation. The asbestos gasket is a good thermal insulation material, which can withstand high temperature up to 1700 degrees Celsius.

[0035] The high temperature resistant shell also includes a first silica gel fixing ring 7 and a second silica gel fixing ring 13; the first silica gel fixing ring is arranged above the silica gel upper cover 8 for fixing the silica gel upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com