A state monitoring system and method for ultrasonic cutting acoustic spindle

A condition monitoring system and ultrasonic cutting technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems affecting the real-time, reliability and safety of acoustic spindle state monitoring, lack of ultrasonic cutting acoustic spindle comprehensive fault parameters Monitoring system, affecting the market development of domestic ultrasonic processing equipment, etc., to improve the quality of after-sales service, reduce after-sales service costs, and enhance the competitiveness of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment;

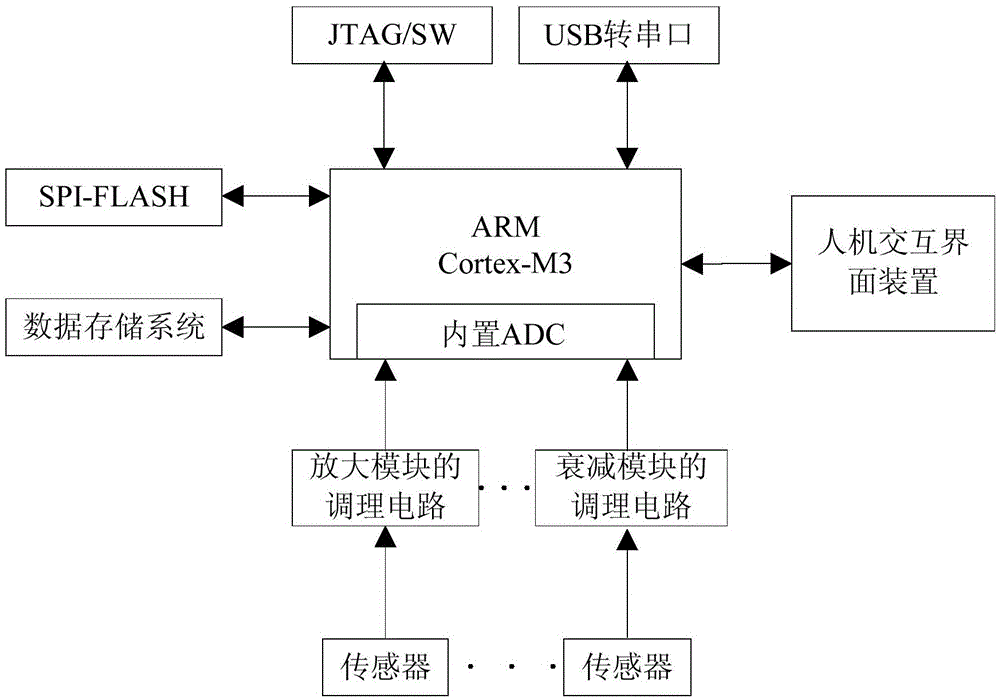

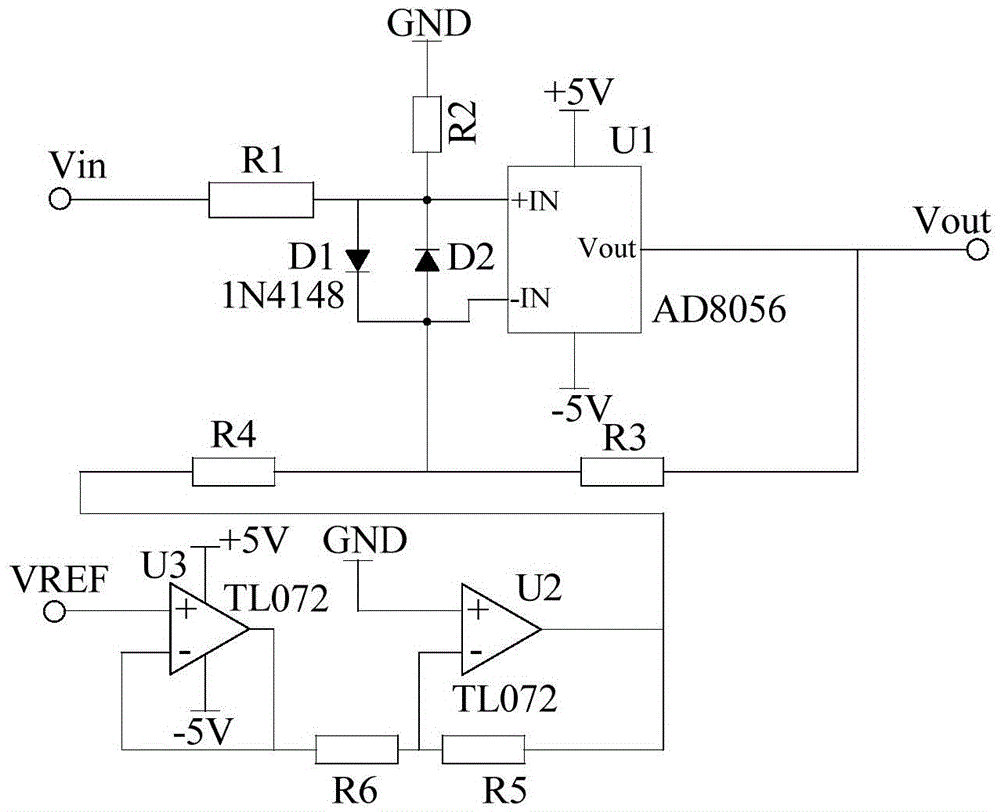

[0035] Such as figure 1 As shown, the ultrasonic cutting acoustic spindle state monitoring system and method provided by the present invention include a main control MCU, a human-machine interface interaction device, a data acquisition system, and a data storage system. The data acquisition system is connected to the ARM Cortex-M3 microprocessor and connected to the sensor used for monitoring to obtain the common fault parameters of the ultrasonic cutting sound spindle. The sensor and the internal ADC amplify and filter the voltage signal output by the sensor through the conditioning circuit. Converted to meet the voltage range of the ADC input; the human-computer interaction interface device is connected with the ARM Cortex-M3 microprocessor for displaying the data of the state monitoring of the ultrasonic cutting sound spindle; the data storage sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com