Dry spinning organic solvent recovery and air circulation process and its device

An organic solvent, dry spinning technology, applied in the direction of rayon recycling, dry spinning, climate sustainability, etc., can solve the problems of increased chemical fiber production costs, poor economy, large power consumption of refrigerators, etc., to achieve solvent The effect of reduced recycling cost, high organic solvent concentration, and reduced solvent unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

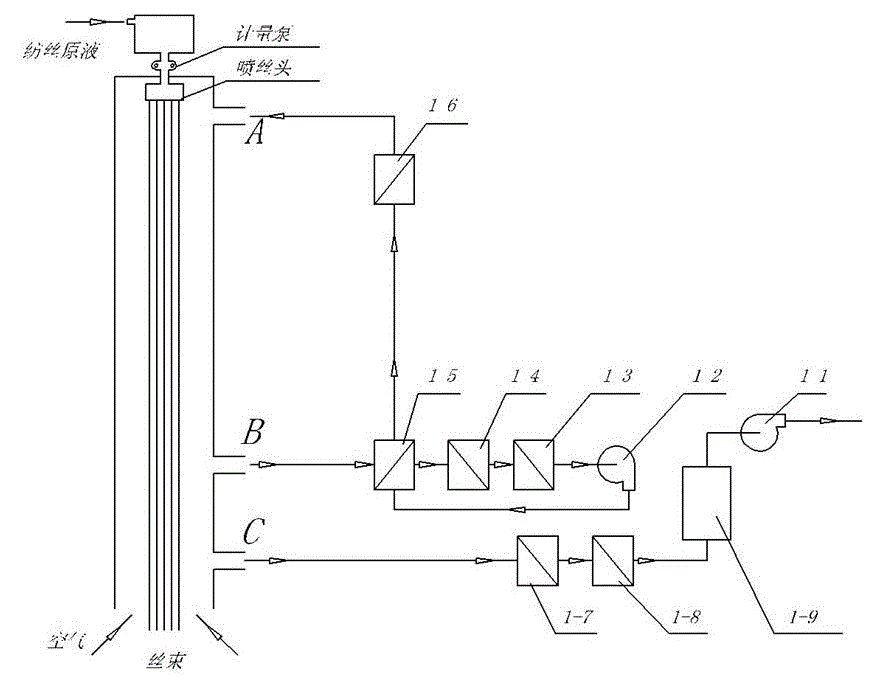

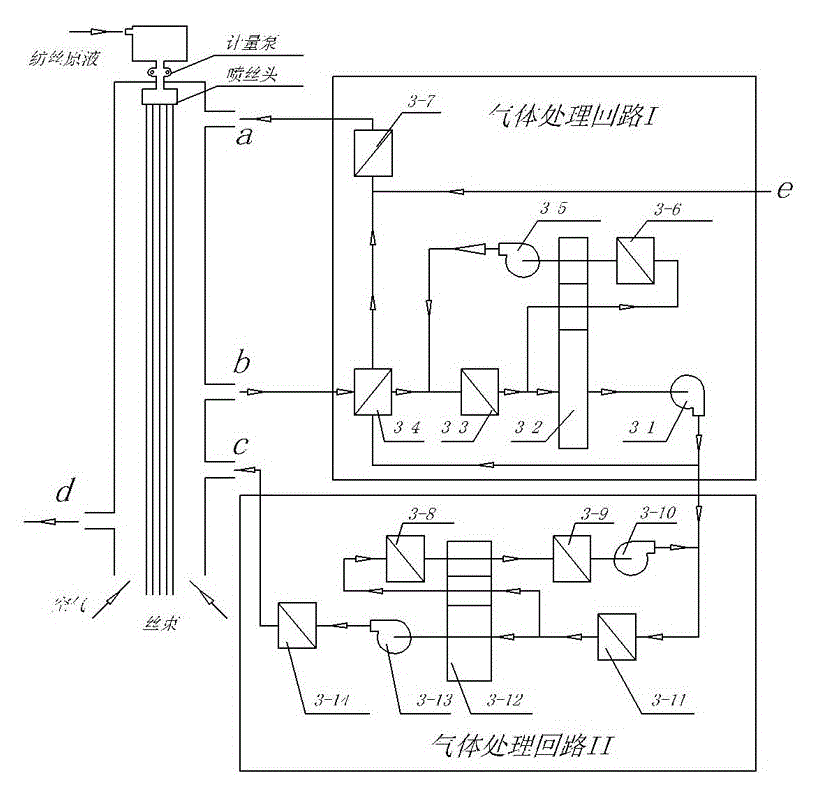

[0034] Such as figure 2 As shown, the dry spinning organic solvent recovery and air recycling process and device of the present invention, point a is the inlet of high temperature gas; point b is the exhaust port of the gas containing organic solvent; point c is the inlet of sub-high temperature gas Port; point d is the exhaust port of the cooling air, and an exhaust fan is installed at point d. Its function is to use workshop air to cool the tow. Most of the air discharged from point d is the air entering from the bottom of the spinning yong. A small amount is the gas that enters the spinning Yonge from point c, and the air discharged from point d does not contain any organic solvents; in addition, the air that enters from the bottom of the spinning Yonge does not enter the gas processing system of the spinning Yonge. That is, in the present invention, there is no phenomenon that the air entering from the bottom of the spinning shaft causes the gas moisture content of the spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com