Method for comprehensive reclaiming elements by treating laterite-nickel ore by combination of chemical waste sulfuric acid and hydrochloric acid

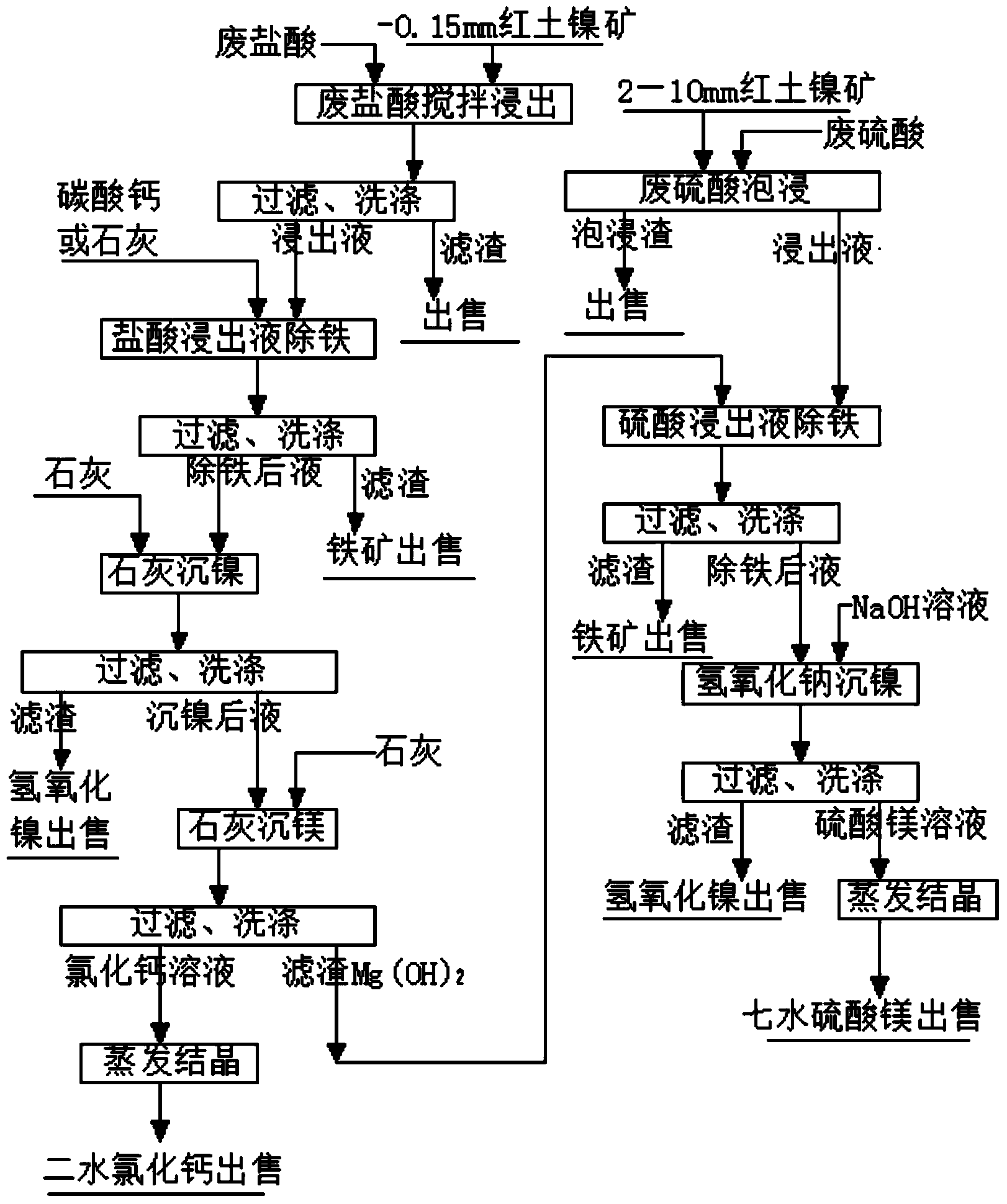

A technology of laterite nickel ore and waste sulfuric acid, which is applied in the direction of improving process efficiency, can solve the problems of high processing cost and cannot be comprehensively utilized, and achieves the effects of simple process path, small production scale and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Stirring and leaching with hydrochloric acid

[0030] at 12m 3 Put into the mixing tank after preparation of laterite nickel ore ore - 0.15mm (less than 0.15mm) pulp 5t. Its chemical composition is shown in the table below.

[0031] -0.15mm pulp chemical composition

[0032] weight t

Concentration%

containing dry ore

Ni%

Fe%

Mg%

SiO 2 %

5

30

1.5

1.6

18

8.0

40

[0033] Add 4.5t of waste hydrochloric acid with a mass fraction of 20% HCl, heat to a temperature of 80°C, stir and leaching for 3 hours at ℃, and the leaching is completed. 2 Filter with a plate and frame filter press, add 0.75t of water to the filter press and wash the filter residue directly, and combine the filtrate and washing water. Obtain leaching residue, hydrochloric acid leaching solution, its chemical composition is as follows.

[0034] Chemical composition of leaching residue

[0035] wet weight

dry weight ...

Embodiment 2

[0086] 1. Stirring and leaching with hydrochloric acid

[0087] at 2m 3 1t of laterite nickel ore preparation - 0.15mm slurry is put into the stirring tank. Its chemical composition is shown in the table below.

[0088] -0.15mm pulp chemical composition

[0089] weight t

Concentration%

containing dry ore

Ni%

Fe%

Mg%

SiO 2 %

1

30

0.3

1.4

18

7.6

41

[0090] Add 0.9t of waste hydrochloric acid with a mass fraction of 20% HCl, heat to a temperature of 70°C, stir and leaching for 6 hours, the leaching is complete, and use a filter area of 10m 2 Filter with a plate and frame filter press, add 0.15t of water to the filter press and wash the filter residue directly, and combine the filtrate and washing water. Obtain leaching residue, hydrochloric acid leaching solution, its chemical composition is as follows.

[0091] Chemical composition of leaching residue

[0092] wet weight

...

Embodiment 3

[0143] 1. Stirring and leaching with hydrochloric acid

[0144] at 3m 3 1t of laterite nickel ore preparation - 0.15mm slurry is put into the stirring tank. Its chemical composition is shown in the table below.

[0145] -0.15mm pulp chemical composition

[0146] weight t

Concentration%

containing dry ore

Ni%

Fe%

Mg%

SiO 2 %

1

30

0.3

1.7

20

6.0

41

[0147] Add 1.8t of waste hydrochloric acid with a HCl mass fraction of 10%, heat to a temperature of 75°C, stir and leaching for 4.5h, the leaching is complete, and use a filter area of 10m 2 Filter with a plate and frame filter press, add 0.15t of water to the filter press and wash the filter residue directly, and combine the filtrate and washing water. Obtain leaching residue, hydrochloric acid leaching solution, its chemical composition is as follows.

[0148] Chemical composition of leaching residue

[0149] wet weight

Mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com